Large-scale turbocharged diesel engine with energy recovery device

A diesel engine and turbocharging technology, applied to engine components, combustion engines, machines/engines, etc., can solve the problem of converting energy that cannot be recovered into a more useful form, reducing the response of the turbocharger to accelerate, and the overall structure is huge and other problems, to achieve the effect of reducing the heat exchange area, increasing the gas velocity, and reducing the amount of piping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the following detailed description, a large turbocharged diesel engine in the form of a large two-stroke diesel engine according to the invention will be described by means of a preferred embodiment.

[0053] The construction and operation of large turbocharged diesel engines, such as large two-stroke diesel engines of the crosshead type, are well known and need not be further described herein. A detailed description regarding boost operation and the exhaust system is provided below.

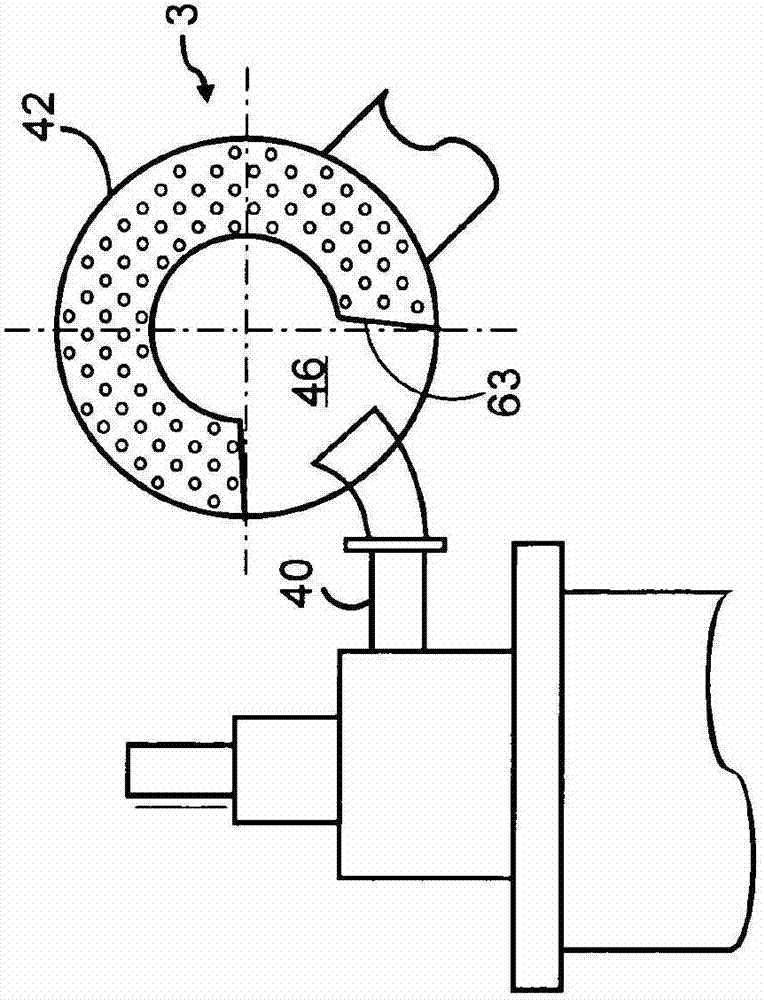

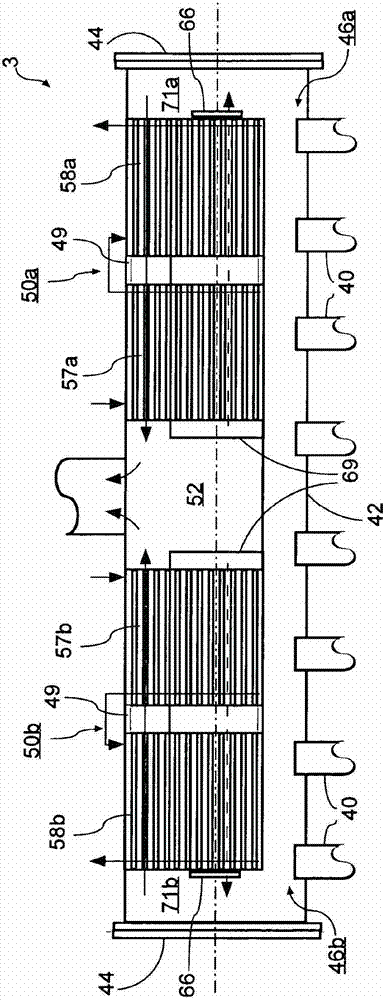

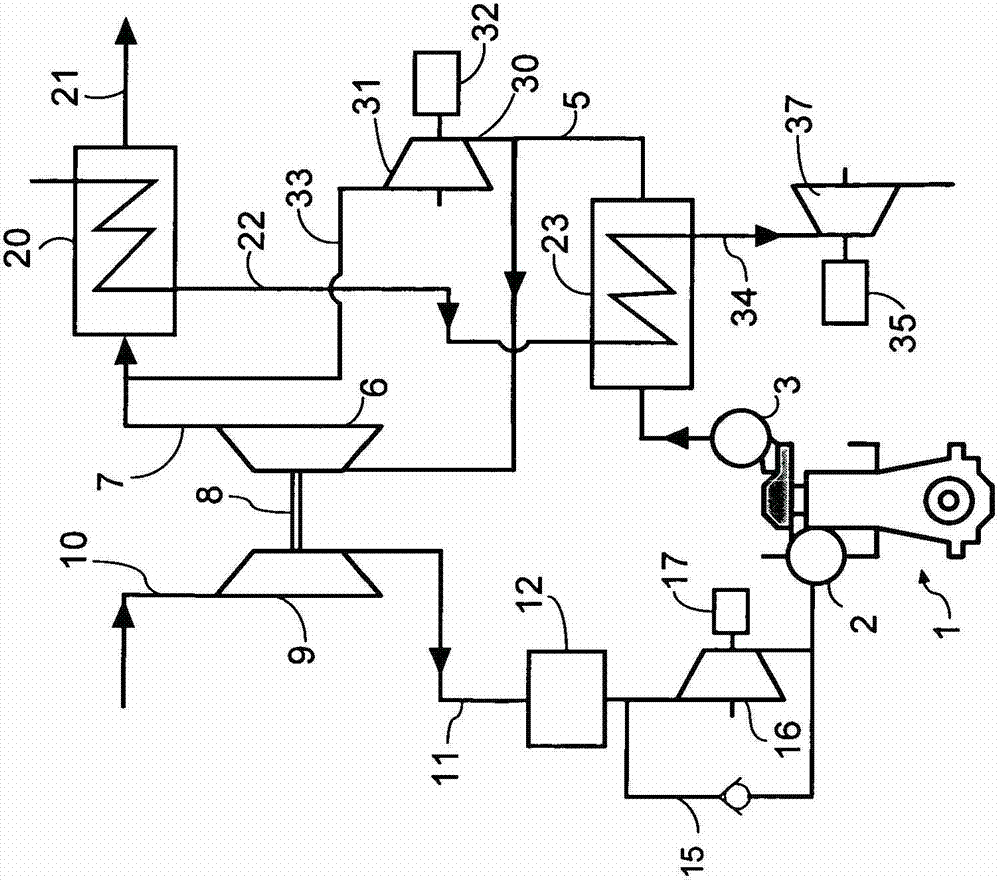

[0054] figure 1 A first embodiment of the upper region of a large two-stroke diesel engine 1 according to the invention is shown. The engine is provided with a plurality of cylinders arranged in-line alongside each other. Each cylinder is provided with an exhaust valve (not shown) associated with the cylinder head. The exhaust passage can be opened or closed by an exhaust valve. The manifold connects the corresponding exhaust channel to the exhaust receiver 3 . The exhaust receive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com