Rotation detection sensor mounting structure and hub unit

A technology of rotation detection and installation structure, applied in the field of hub unit, can solve problems such as the inability to guarantee the stable output and detection of the sensor, the need for stability and safety, and the inability to guarantee the detection of wheel rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

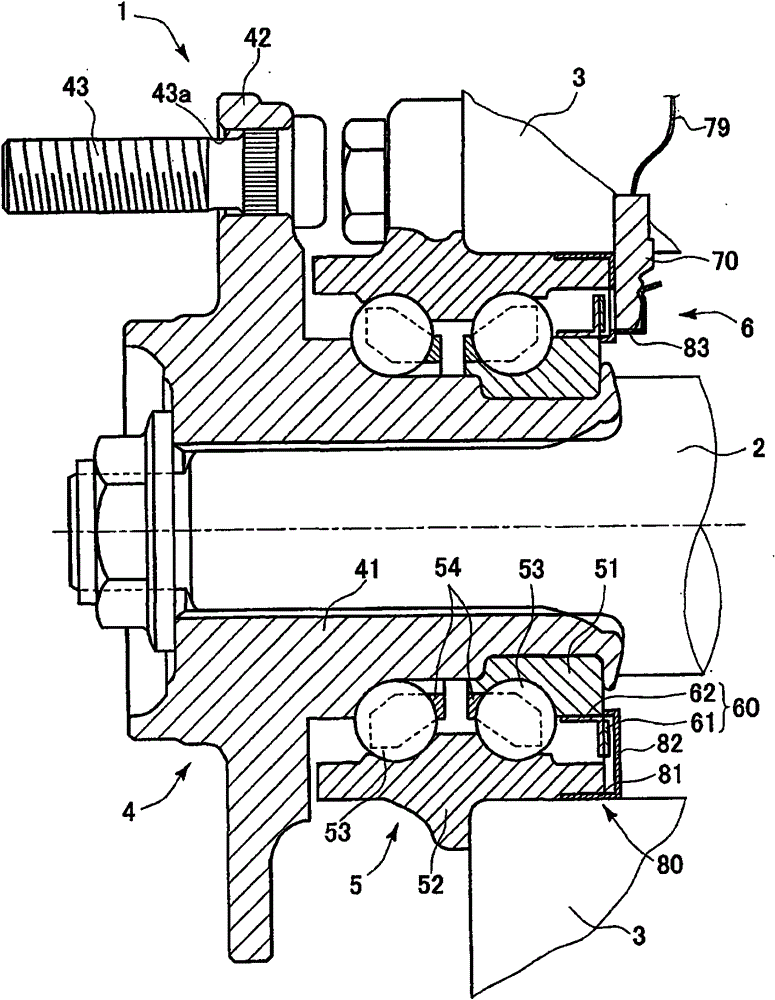

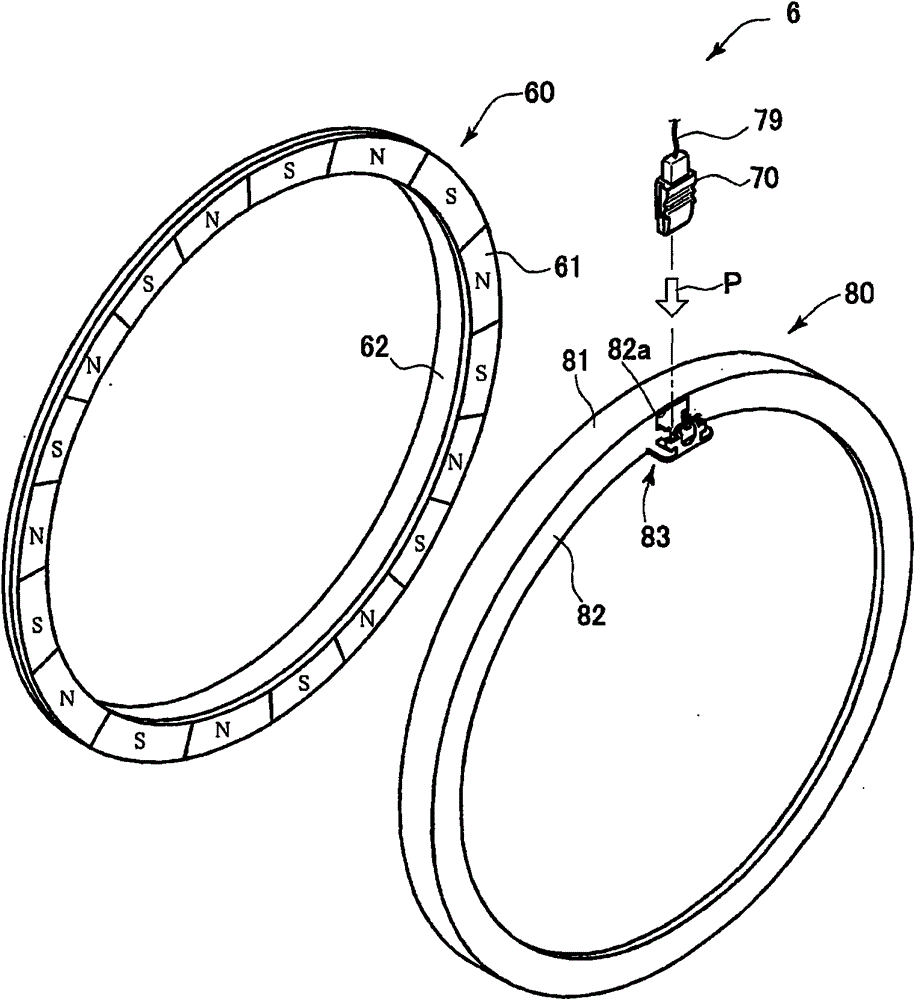

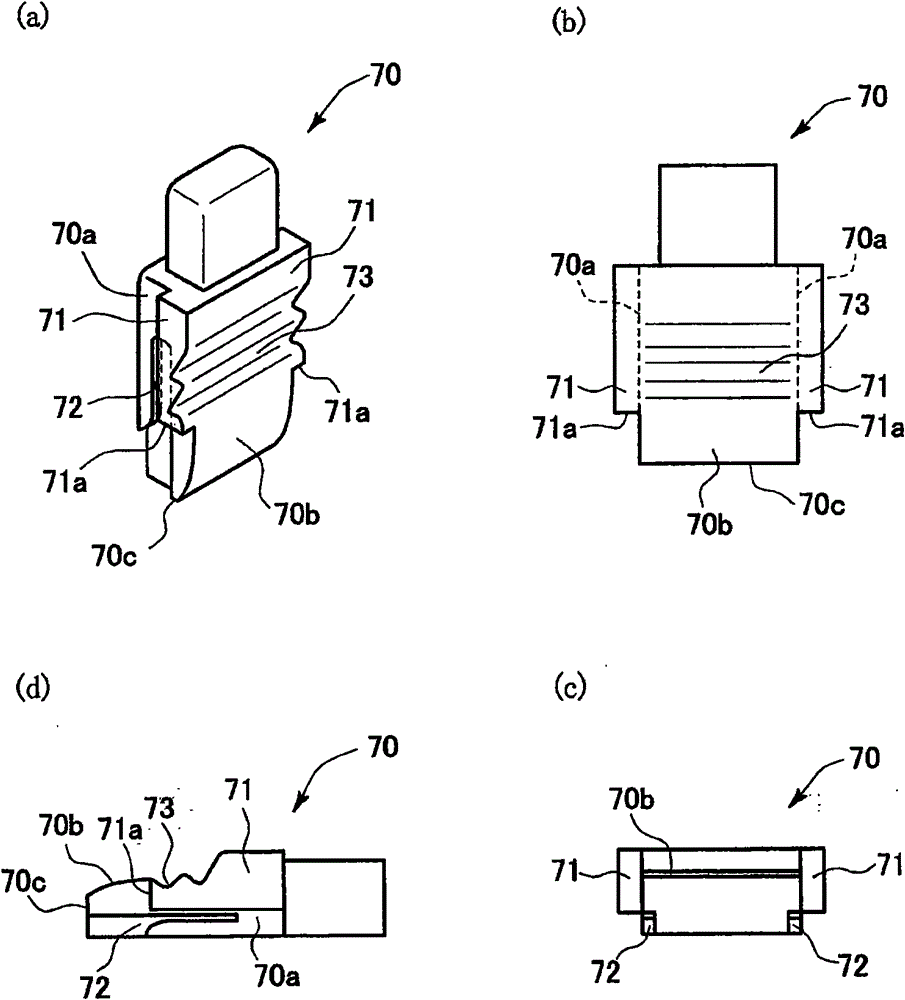

[0056] A first embodiment of the present invention will be described below with reference to the embodiments shown in the drawings. figure 1 is a schematic diagram showing an example of a sectional configuration of a hub unit equipped with the rotation detection unit of the present invention, figure 2 is an exploded perspective view showing an example of a rotation detection unit according to an embodiment of the present invention, image 3 are perspective, plan, front and side views showing an example of a head, Figure 4 is a perspective view, a plan view, a front view and a side view showing an example of a holding portion, Figure 5 is a perspective view showing an example of a state where the head is mounted in the holding portion, and Image 6 yes Figure 5 side view. It should be noted that in figure 1 In , the left-hand side in the figure indicates the vehicle outer side, and the right-hand side in the figure indicates the vehicle inner side.

[0057] Such as f...

no. 2 example

[0075] Next, an embodiment of a rotation detection sensor mounting structure according to a second embodiment of the present invention will be described with reference to the drawings. Figure 7 are perspective and side views showing an example of a head, Figure 8 is a perspective view, a plan view, a front view and a side view showing an example of a holding portion, Figure 9 is a perspective view showing an example of a state where the head is mounted in the holding portion, and Figure 10 yes Figure 9 side view. It should be noted that in the following description, different parts from the embodiments described above will be mainly described, and parts similar to those of the foregoing embodiments are given like reference numerals so that descriptions are omitted or simplified.

[0076] Next, pass Figure 7 with 8 Detailed forms of the head portion 70 and the holding portion 83 in the second embodiment will be described. As in the case of the foregoing embodiments,...

no. 3 example

[0092] Next, an embodiment of a rotation detection sensor mounting structure according to a third embodiment will be described with reference to the drawings. Figure 16 are perspective and side views showing an example of a head, Figure 17 is a perspective view and a side view showing an example of a holding portion, Figure 18 is a perspective view showing an example of a state where the head is mounted in the holding portion, and Figure 19 yes Figure 18 side view.

[0093] As in the case of the foregoing embodiments, the head portion 70 and the holding portion 83 constitute a part of the rotation detection unit 6 for detecting a change in rotation of the drive shaft 2 of the hub unit 1 . The head 70 detects the rotation of the pulsar ring 60 in the hub unit 1, and the holding portion 83 is arranged on the annular cover member 80 to hold the head 70 on the vehicle inner side (refer to figure 1 , 2 ). The head portion 70 is formed of a polymer material such as resin,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com