Anti-loosening threaded pair comprising limiting faces and anti-loosening threaded parts

A technology of limiting surfaces and threaded parts, which is applied in the direction of threaded fasteners, nuts, bolts, etc., can solve the problems of broken threaded connection structural parts, loose threaded connection failure, and reduced connection force, so as to improve fastness and facilitate The effect of repeated use and moderate tightening torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

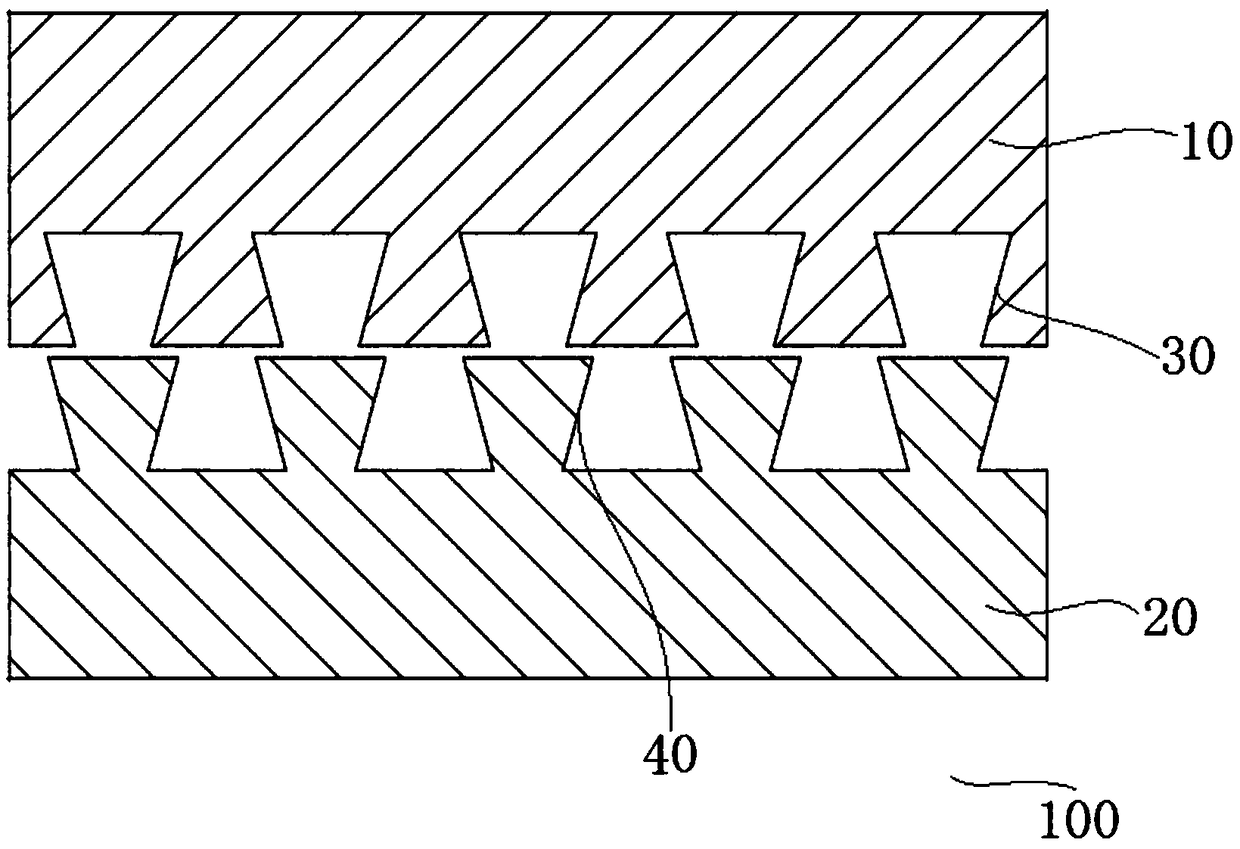

[0085] As shown in FIG. 1( a ) and FIG. 1( b ), the anti-loosening thread pair 100 including the limiting surface is mainly composed of a first threaded part 10 and a second threaded part 20 . An inner hole may be processed on the first screw member 10, and the inner wall of the inner hole may be processed with first thread teeth extending along a helical line. A rod-shaped structure can be processed on the second screw member 20, and the outer wall surface of the rod-shaped structure of the second screw member 20 can be processed with second thread teeth extending along a helical line, and the second thread teeth can correspond to the first thread teeth . In this embodiment 1, the first threaded member 10 is tightened to the left relative to the second threaded member 20, and the left-right direction shown in Figure 1(b) is the load-bearing direction, thereby forming a force-bearing mating surface and a non-bearing Force fit surface.

[0086] The first limiting surface 30 i...

Embodiment 2

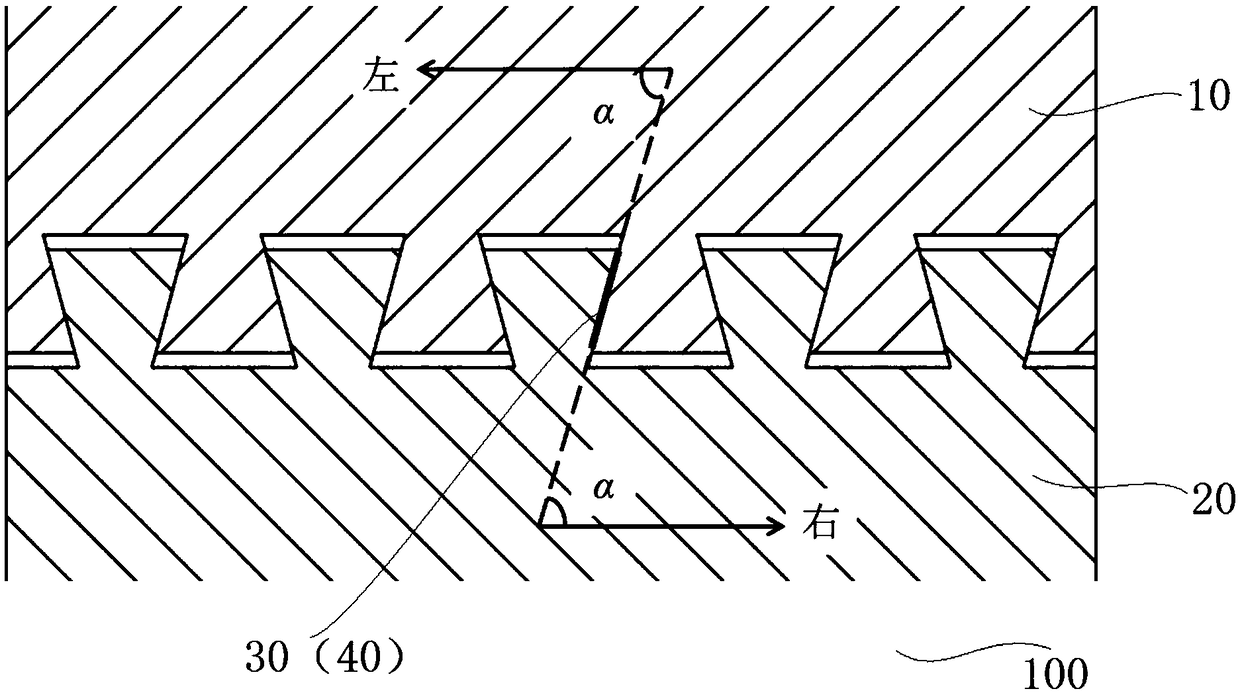

[0088] As shown in Figure 2 (a) and Figure 2 (b), the main structure of the anti-loosening thread pair 100 comprising the limiting surface in the present embodiment 2 is basically the same as the above-mentioned embodiment, in the present embodiment 2, the first A threaded member 10 is screwed leftward relative to the second threaded member 20, and the left-right direction as shown in FIG. 2(b) is the bearing direction, thereby forming a force-bearing mating surface and a non-force-bearing mating surface.

[0089] The first limiting surface 30 is processed as a part of the first force-bearing mating surface of the first threaded part 10, and the second limiting surface 40 is processed as a part of the second force-bearing mating surface of the second threaded part 20, The first limit surface 30 and the second limit surface 40 overlap and form a straight line in the cross-sectional view shown in Figure 2 (b), the extension of the straight line (i.e. the extension of the coincide...

Embodiment 3

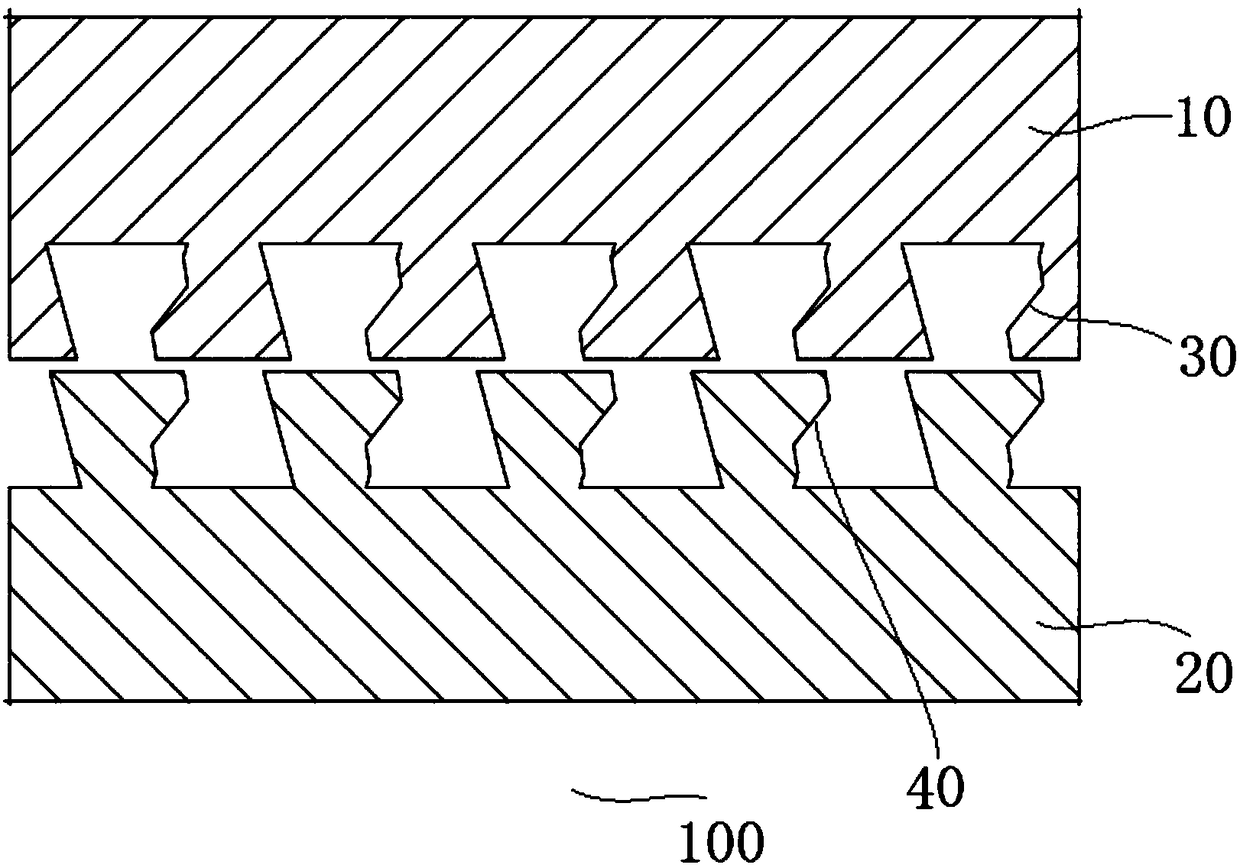

[0091] As shown in Figure 3 (a) and Figure 3 (b), the main structure of the anti-loosening thread pair 100 comprising the limiting surface in the present embodiment 3 is basically the same as the above-mentioned embodiment, in the present embodiment 3, the first A threaded member 10 is tightened to the left relative to the second threaded member 20, and the left and right direction as shown in FIG.

[0092] The first limiting surface 30 is processed as a part of the curved surface on the first force-bearing mating surface of the first threaded part 10 , and the second limiting surface 40 is processed as a part of the second force-bearing mating surface of the second threaded part 20 Curved surface, the first limit surface 30 and the second limit surface 40 overlap and form a curve segment in the cross-sectional view shown in Fig. The angle formed by the bearing directions of the first threaded member 10 and the second threaded member 20 is an acute angle α, which effectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com