Method for simulating electric drive control system under brake working condition of electric-wheel truck

A technology for electric wheel vehicles and dynamic braking, applied in general control systems, control/regulation systems, brakes, etc., can solve the problems of increased system debugging, difficulty in controller design, difficulty, etc., to save experimental costs and shorten development cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

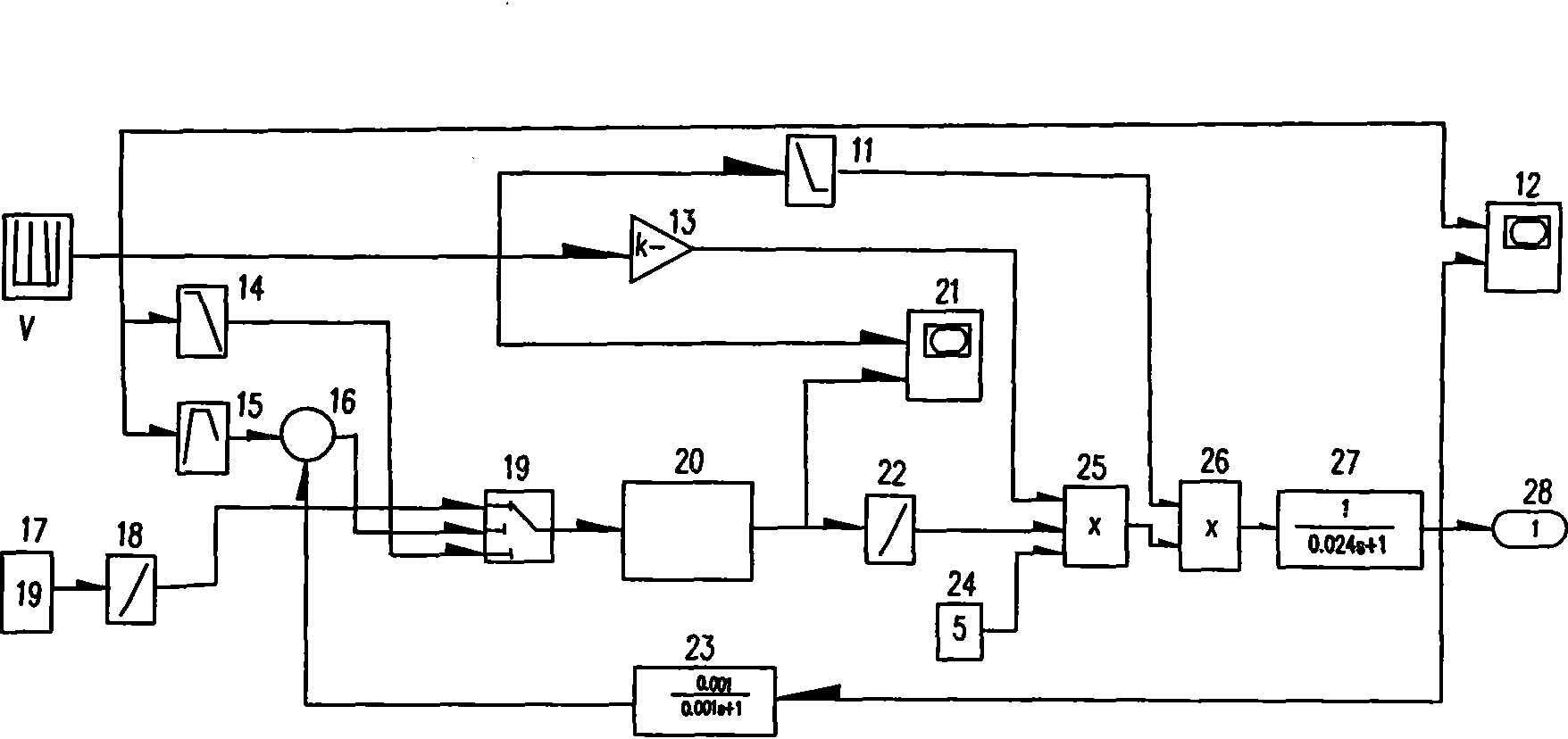

[0035] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

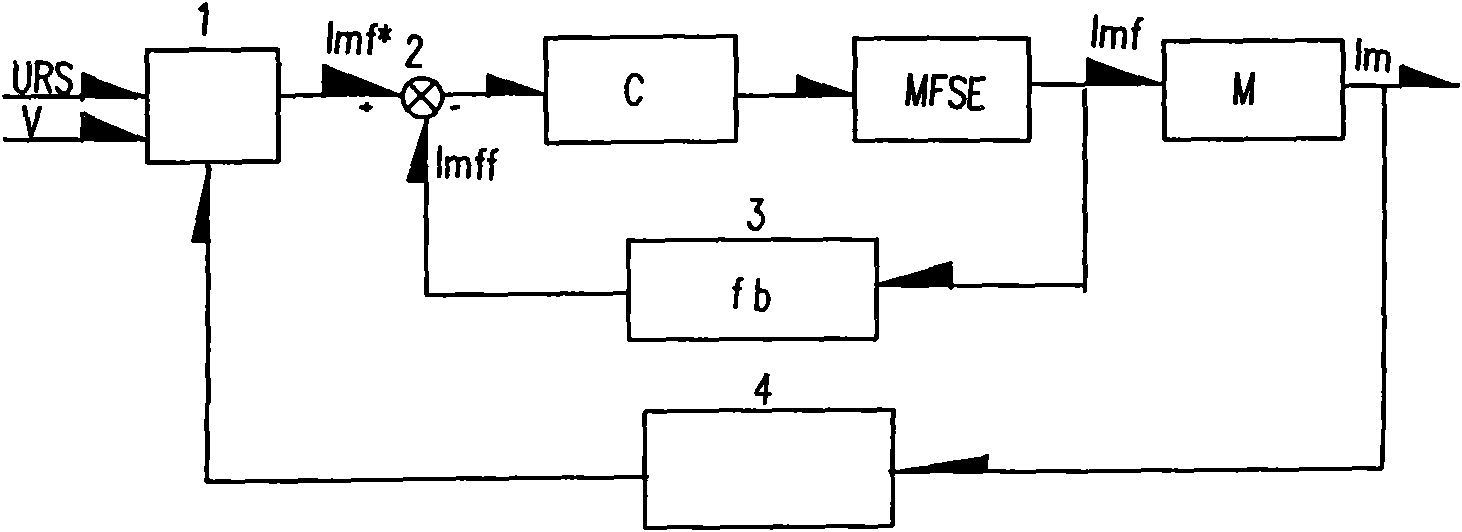

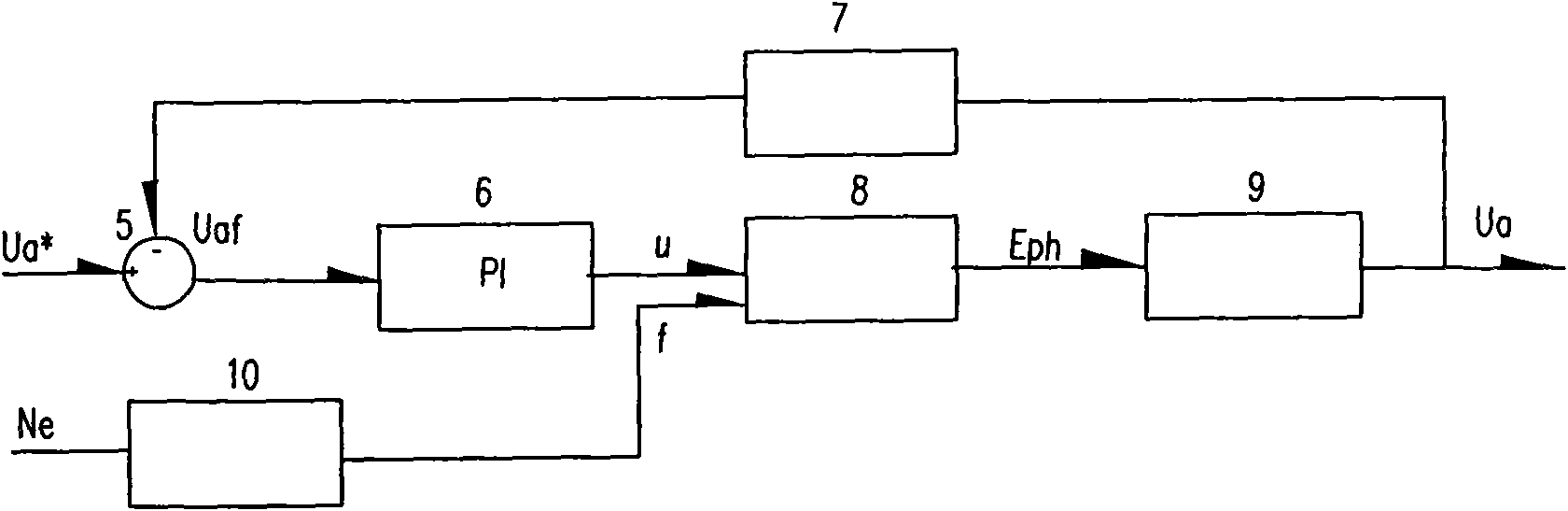

[0036] The simulation method of the electric transmission control system under the dynamic braking condition of an electric wheel vehicle according to the present invention is characterized in that under the dynamic braking condition, the control system is composed of a wheel motor control part and a main generator control part:

[0037] 1) wheel motor control part:

[0038] (1) Calculate the characteristic curves of excitation current and armature current according to the data of relevant technical materials,

[0039] (2) Analyze the working logic under braking conditions, and get U RS -Imf*, V-Imf*, V-Ia*, Imf*-Imf, V-1 / R characteristic curves of each link, where U RS is the brake pedal signal, Imf* is the excitation current of the wheel motor, V is the vehicle speed, Ia* is the armature current of the wheel motor, Imf is the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com