Optical performance recovery device, recovery method and optical system used for the device

A technology of optical system and optical equipment, applied in the field of invention, can solve problems such as difficult long-term monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

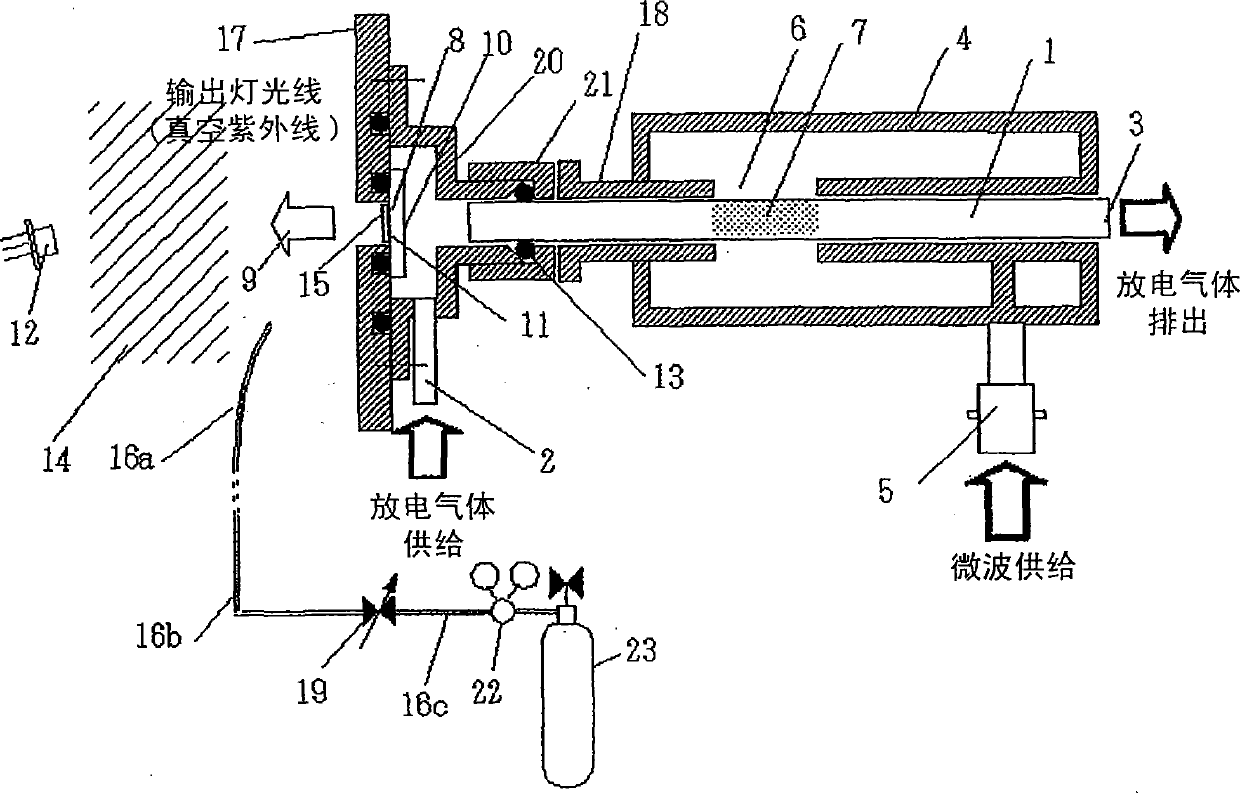

[0135] figure 1 It is a diagram showing the structure of the microwave excited hydrogen ultraviolet lamp according to the first example of the first preferred embodiment of the present invention.

[0136] The holder (flange) 17 connected to the light transmission window 8 is of a disc shape, and its center is aligned with the hole of the discharge tube 1, and it includes an opening with a larger diameter than the inner diameter of the discharge tube. The window flange 17 includes an O-ring groove to seal the entire opening of the light transmission window 8, a hollow cover-shaped assembly frame 20, a bolt hole for attaching it, and is connected to the discharge tube 1 for use with a window flange 17 O-ring groove to maintain vacuum.

[0137] The internal structure of the assembling frame 20 adopts two levels of concentric circles and limits the space for accommodating the light transmission window 8 and the space surrounded by the discharge tube 1. At the end surrounding the disc...

Embodiment 2

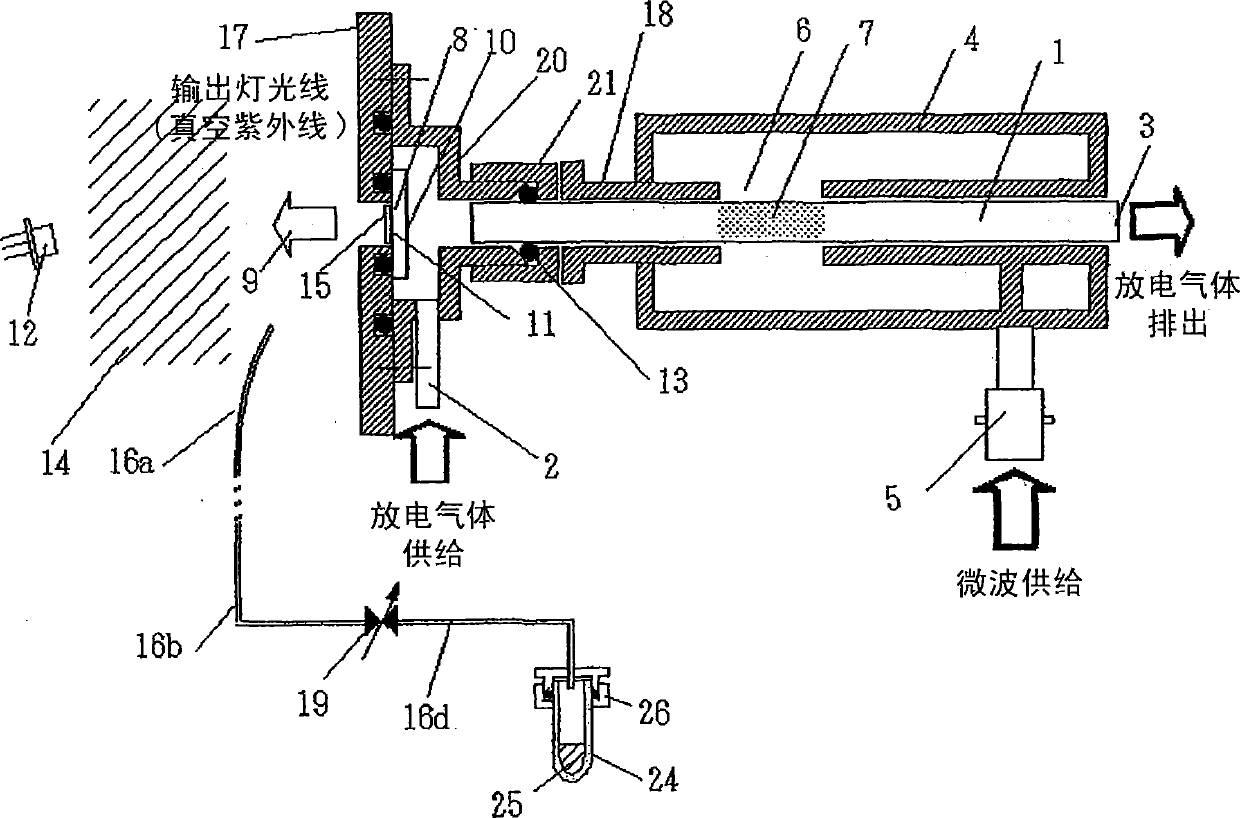

[0161] figure 2 It is a diagram showing a microwave-excited hydrogen ultraviolet lamp for explaining the second example of the first preferred embodiment of the present invention. Other detailed descriptions of the same structure and operating elements as those described in Embodiment 1 are omitted here. The specifications of the light transmission window 8 are the same as those described in the first embodiment. In addition, the photodiode 12 is positioned as a device for monitoring the light output of the lamp to receive the light output of the light emitted by the lamp 9.

[0162] The steam is supplied to the vacuum zone 14 by the following method and adjusted to a prescribed gas partial pressure. A glass tube 24 (diameter of Φ6 mm) filled with 1 mL of water 25 (purified water for distillation, ion exchange treatment, and filtration) is connected to a tube 16d through a flange 17. The structure of the flange 17 of the combined O-ring seals the glass tube to isolate it from ...

Embodiment 3

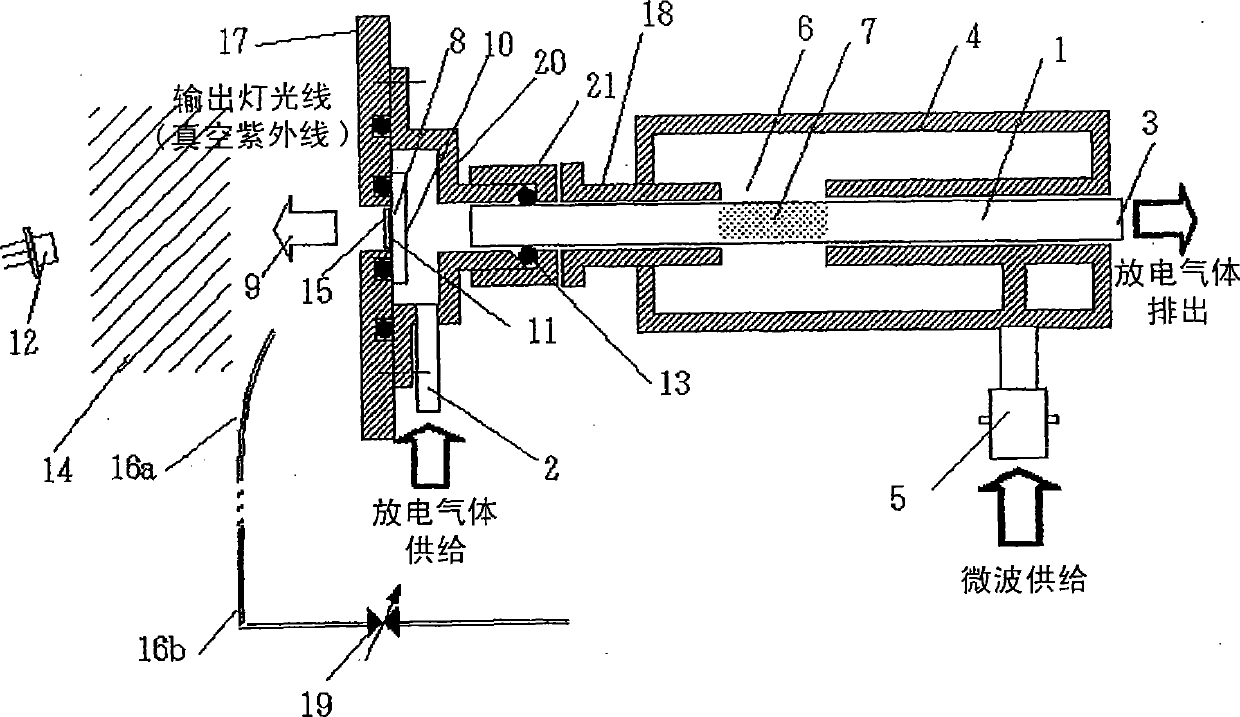

[0173] image 3 It is a diagram showing a microwave-excited hydrogen ultraviolet lamp for explaining the third example of the first preferred embodiment of the present invention. Other detailed descriptions of the same structure and operating elements as those described in Embodiment 1 are omitted here. The specifications of the light transmission window 8 are the same as those described in the first embodiment. In addition, the photodiode 12 as a device for monitoring the output of the lamp is positioned to receive the light output of the light 9 emitted by the lamp.

[0174] The atmospheric components are supplied to the vacuum zone 14 and adjusted to the prescribed gas partial pressure by the following prescribed method.

[0175] After passing through the adjustable hole of the variable leakage valve 19, the atmospheric components are supplied to the vacuum zone 14 through a tube open to the atmosphere allowing the atmospheric components to flow through the tube 16b, and enter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com