High-strength hot-dip galvanized steel sheet and method for producing the same

A technology of hot-dip galvanized steel sheet and manufacturing method, which can be applied to manufacturing tools, hot-dip galvanizing process, heat treatment furnace, etc., and can solve the problems of reduced workability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

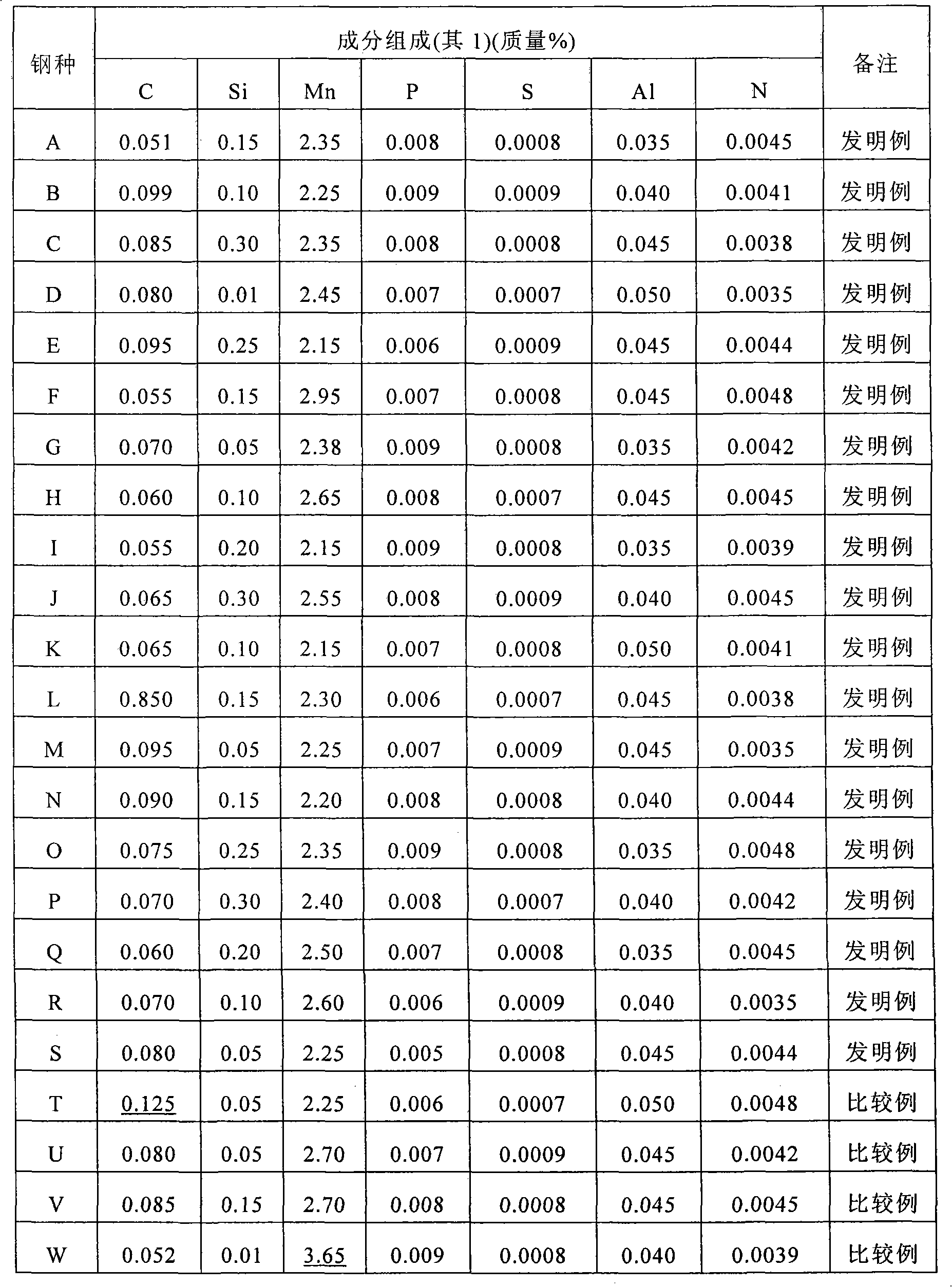

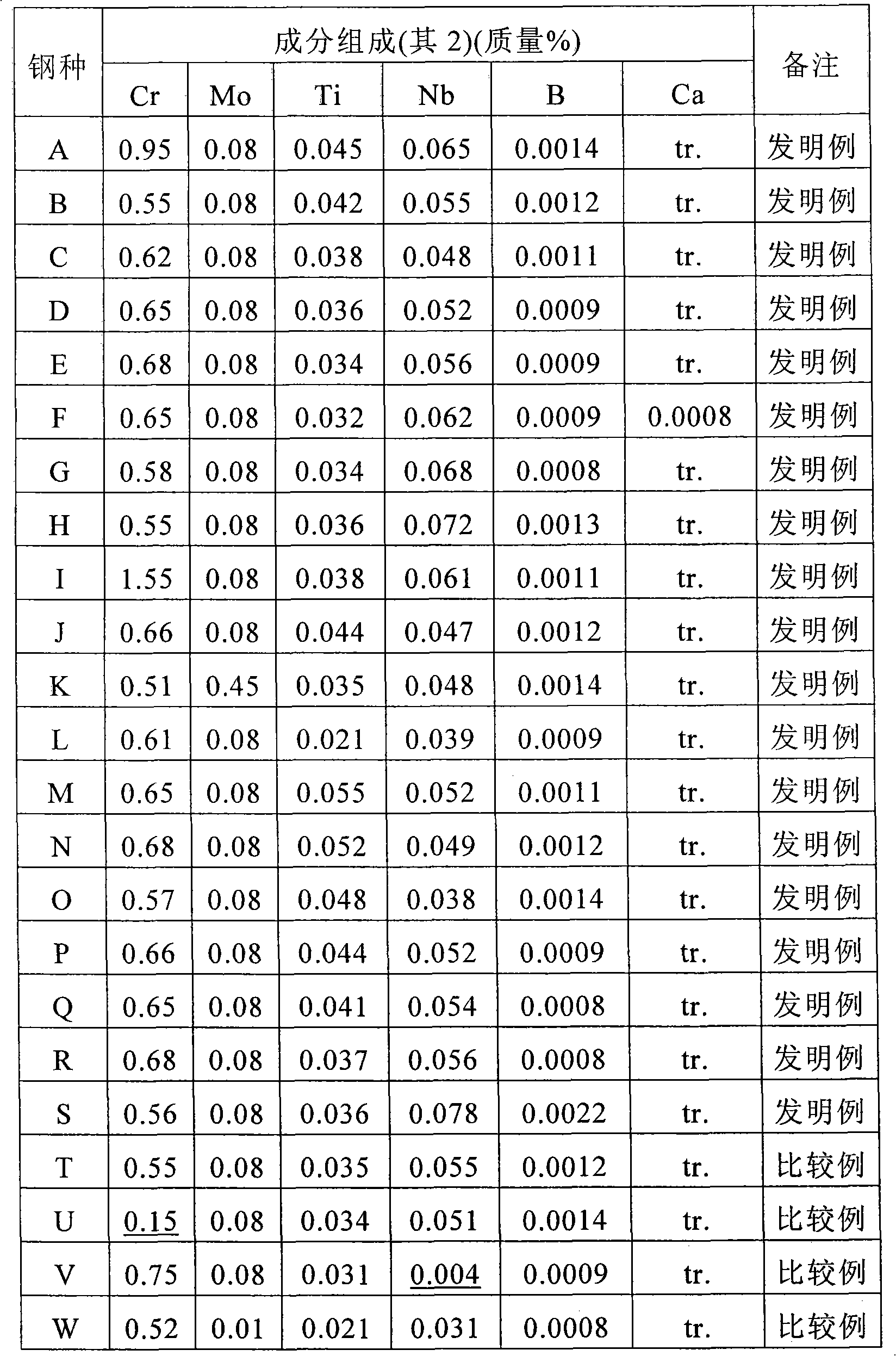

[0127] The steels with the compositions shown in Tables 1 and 2 were melted to form steel slabs, and then hot-rolled, pickled, cold-rolled at a rolling ratio of 50%, and Continuous annealing and plating treatment, the thickness of the manufactured plate is 1.4mm and the coating weight per single side is 45g / m 2 Hot-dip galvanized steel sheet and alloyed hot-dip galvanized steel sheet.

[0128] The obtained galvanized steel sheets and alloyed galvanized steel sheets were subjected to the following material tests to study material properties.

[0129] The obtained results are shown in Tables 7 to 10.

[0130] In addition, the material test and evaluation methods of material properties are as follows.

[0131] (1) Structure of steel plate

[0132] The cross-section in the rolling direction and the sheet thickness: 1 / 4 plane position were studied by an optical microscope or a scanning electron microscope (SEM). The grain size of the ferrite phase is measured according to the m...

Embodiment 2

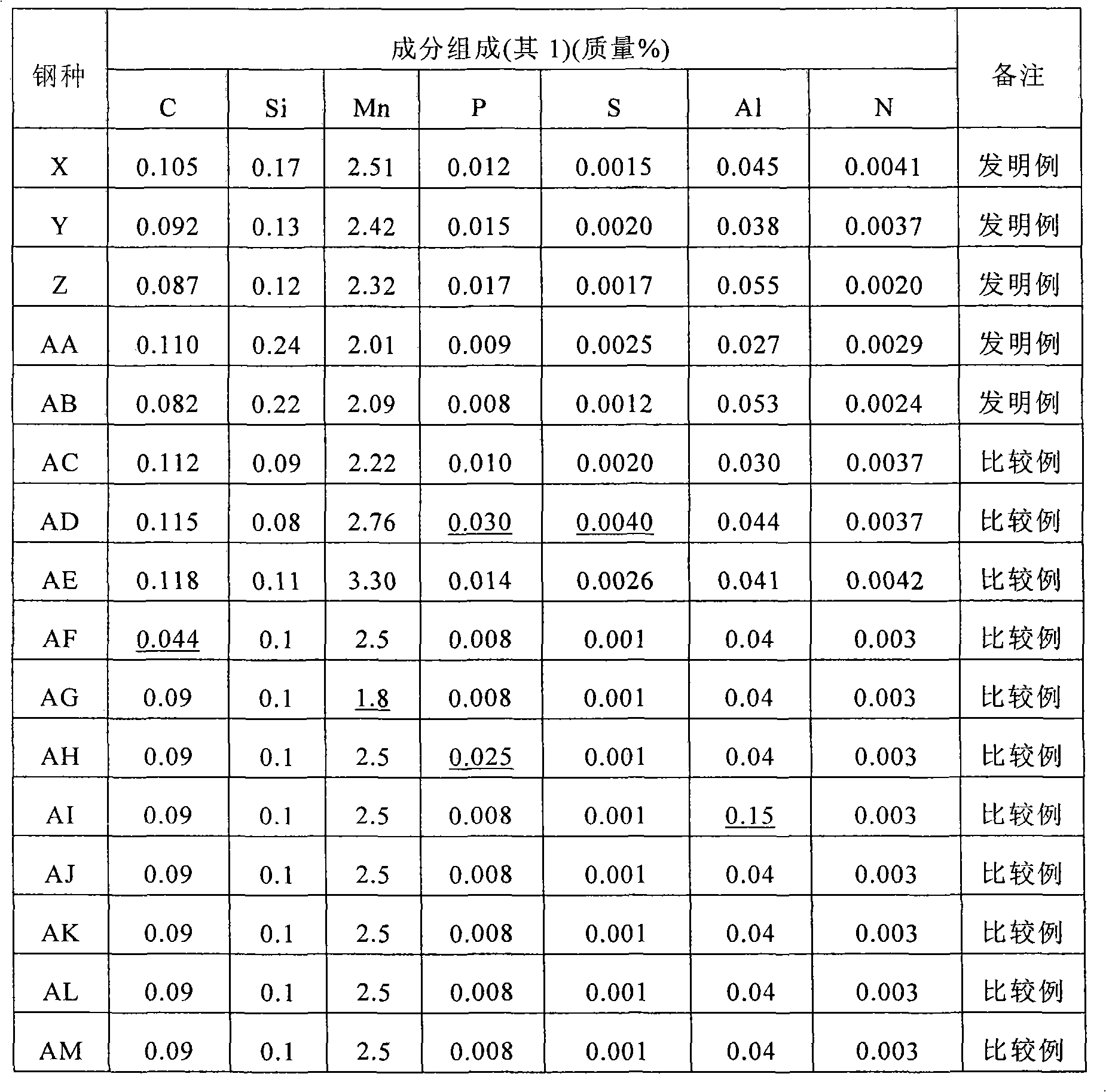

[0179] Hot-dip galvanized steel sheets were manufactured in the same manner as in Example 1 using steels having the composition shown in Table 11. Here, the manufacturing conditions were determined as follows.

[0180] Billet Heating Temperature SRT: 1200°C Finishing Rolling Temperature FT: 910°C

[0181] ·Average cooling rate from finish rolling temperature to (finish rolling temperature -100°C): 40°C / sec

[0182] Coiling temperature CT: 500°C

[0183] ·One-time average heating rate: 20°C / s ·Intermediate temperature: 700°C

[0184] Secondary average heating rate: 5°C / sec

[0185] ·Annealing temperature: 800℃ ·Holding time: 60 seconds

[0186] ・Average cooling rate from holding the annealing temperature: 10°C / sec

[0187] ·Cooling stop temperature: 500℃

[0188] Alloying treatment conditions: plating bath temperature 460°C, alloying treatment conditions 520°C for 20 seconds

[0189] ·Skin pass rate%: 0.3%

[0190] Table 12 and Table 13 show the properties of each hot-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com