Pulsation generating mechanism, connecting flow channel tube, and fluid ejecting apparatus

A technology of fluid jetting and connecting flow paths, applied in the fields of fluid jet scalpel, medical science, surgery, etc., it can solve the problems of insufficient internal pressure, rise, and inability to perform pulsating discharge, and achieve the effect of improving convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

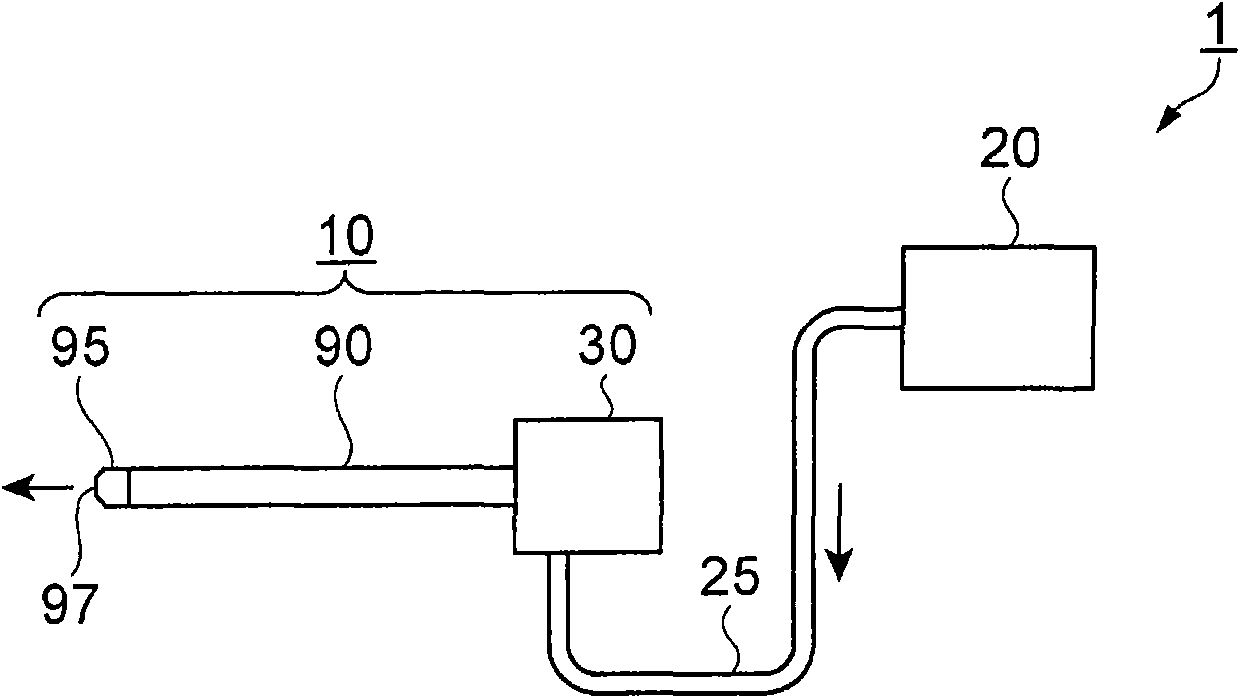

[0063] Next, the configuration of the fluid ejection device 10 according to Embodiment 1 will be described.

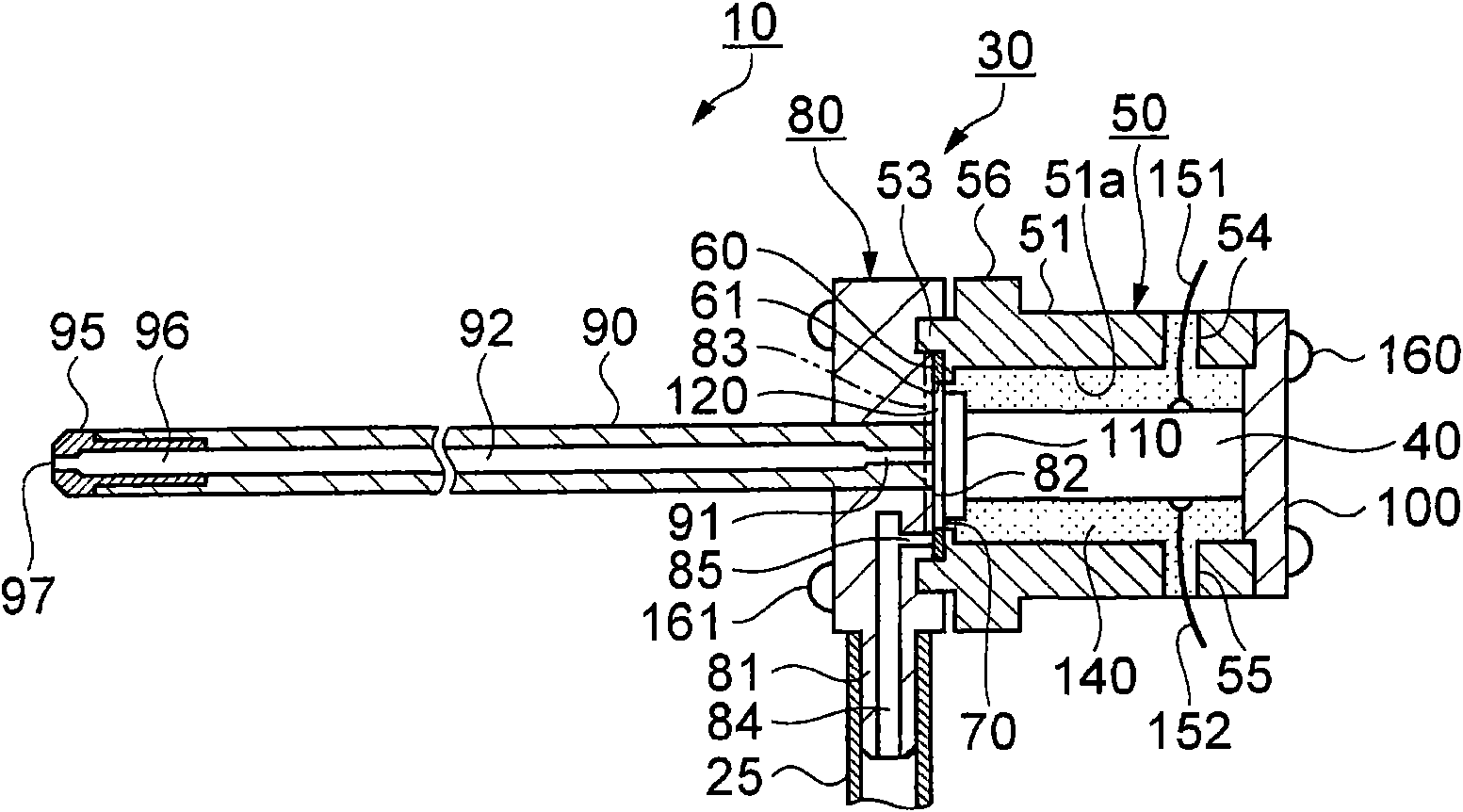

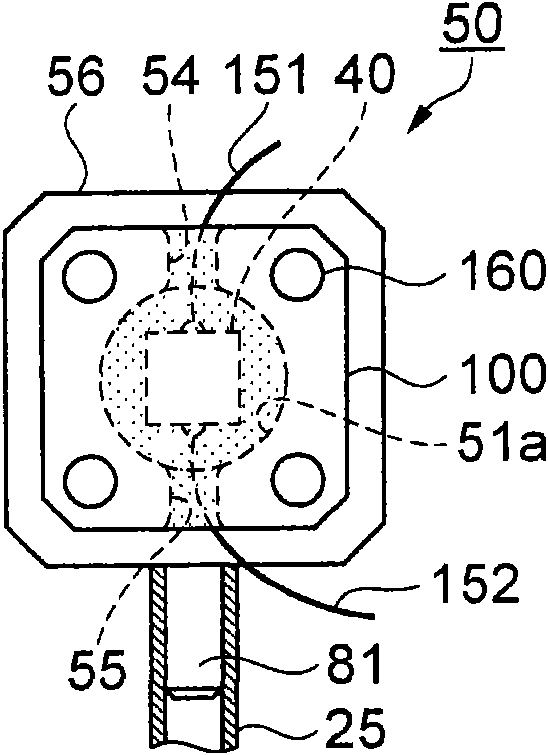

[0064] figure 2 It is a cross-sectional view showing the main structure of the pulsation generating mechanism according to Embodiment 1 cut along the flow path direction of the liquid, image 3 It is a side view shown from the right side of the pulsation generating mechanism, Figure 4 It is a side view shown from the left side of the pulsation generating mechanism.

[0065] First, refer to Figure 2 ~ Figure 4 A schematic configuration of the fluid ejection device 10 will now be described. The fluid ejection device 10 is composed of: a pulsation generating mechanism 30 including a pulsation generating unit that generates pulsation of liquid; and a connection channel pipe 90 having an outlet connection channel 92 and a nozzle 95 for discharging liquid.

[0066] The pulsation generating mechanism 30 has a fluid chamber 120, and the fluid chamber 120 is configured s...

Embodiment approach 2

[0128] Next, Embodiment 2 will be described with reference to the drawings. Embodiment 2 has a feature that, compared to Embodiment 1, an outlet flow path is provided in the first frame, and an outlet connection flow path provided in a connection flow pipe is communicated with the outlet flow path. Therefore, the description will focus on differences from Embodiment 1. FIG.

[0129] Figure 9 It is a sectional view showing a part of the fluid ejection device according to Embodiment 2. exist Figure 9 In the first machine frame 80, an outlet flow path 88 communicating with the fluid chamber 120 is opened, and a connection flow pipe insertion portion 80a protrudes from the opposite side of the fluid chamber 120, and a connecting flow pipe insertion portion 80a is pierced in its central part. Insertion hole 80c.

[0130] Then, the connecting channel tube 90 is inserted into the connecting channel tube insertion portion 80a. An outlet connection flow path 92 is opened in the ...

Embodiment approach 3

[0138] Next, a fluid ejection device according to Embodiment 3 will be described with reference to the drawings. In Embodiment 1 and Embodiment 2, the connection flow pipe 90 is press-fitted and fixed in the pulsation generating mechanism 30 (the first machine frame 80 ), while the feature of Embodiment 3 is that the connection flow pipe 90 can be mounted on the pulsation generating mechanism 30 To disassemble. Therefore, the description will focus on differences from the first and second embodiments described above.

[0139] Figure 10 A fluid ejection device according to Embodiment 3 is shown, Figure 10 (a) is a sectional view showing a part of the fluid ejection device, Figure 10 (b) is to show Figure 10 The cross-sectional view of the E-E cut plane of (a). exist Figure 10 Among them, the fluid ejection device 10 is configured such that in the pulsation generating mechanism 30 , the connecting channel tubes 90 are screwed and fixed to the threaded portions of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com