Wide-temperature-range high-speed impact wear testing machine

A high-speed impact and wear test technology, applied in the direction of testing wear resistance, using repeated force/pulsation force to test material strength, measuring devices, etc., can solve the problem that the impact angle cannot be changed, and achieve convenient research, controllable speed, The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

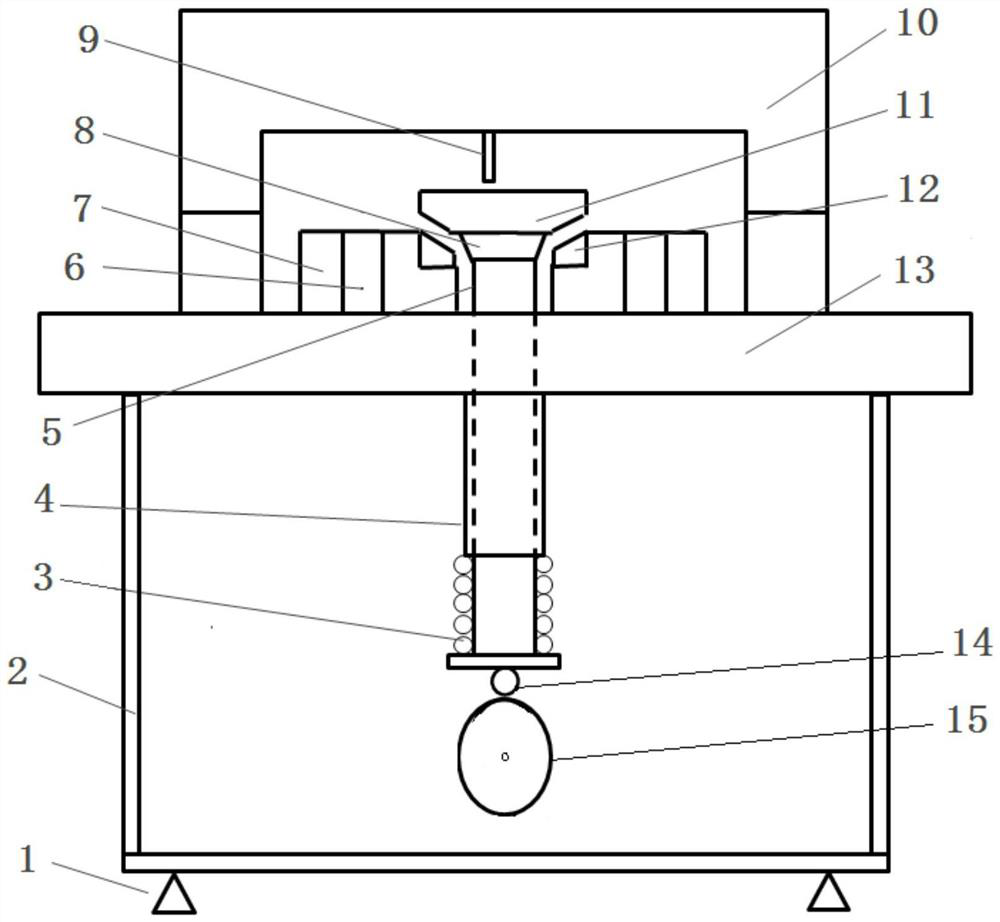

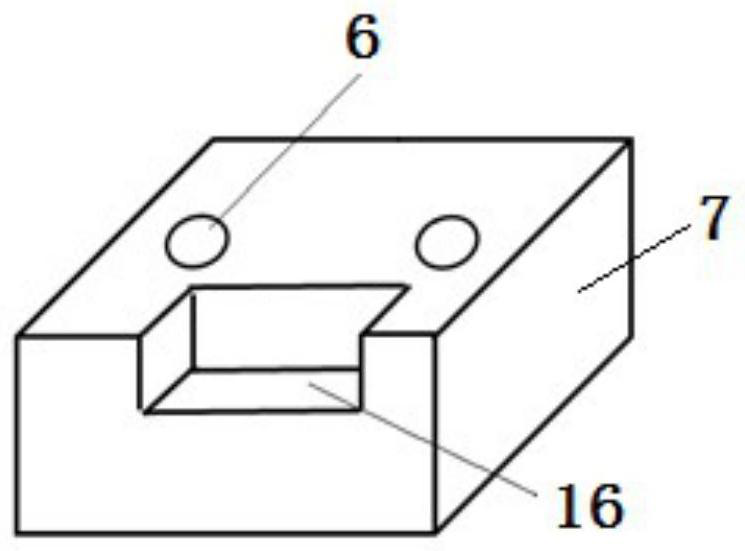

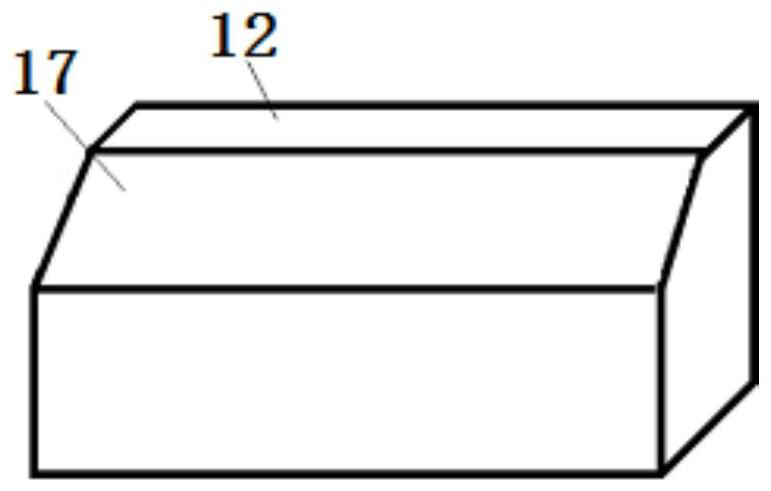

[0033] Such as figure 1 and Figure 4 As shown, a wide temperature range high-speed impact wear testing machine provided by the present invention includes a test frame, a working platform 13 is arranged above the test frame; a high-temperature furnace 10 is arranged on the working platform 13, and an impact test module is arranged in the high-temperature furnace 10 , the impact test module includes two oppositely arranged test block mounts 7, the test block mounts 7 are connected to the working platform 13, the test block mounts 7 are provided with mounting grooves 16, and the test block 12 is installed in the mounting grooves 16, and the test block 12 is provided with a threaded hole 6. When in use, the test block 12 is installed in the installation groove 16 by bolts. The impact block mounting seat 8 is slidably arranged between the two test block mounting seats 7. The impact block mounting seat 8 is disassembled and connected with Impact block 11, the driving mechanism is ...

Embodiment 2

[0043] Such as Figure 5 As shown, on the basis of Example 1, the present invention provides a wide temperature range high-speed impact wear tester, wherein the cam 15 is arranged on one side of the lower end of the ejector rod 5, and also includes a connecting rod 19 whose middle position rotates Erected on the test stand, both ends of the connecting rod 19 are connected with rollers 14, one of which is in contact with the lower end of the push rod 5, and the other roller 14 is in contact with the contour surface of the cam 15.

[0044] A lever-type connecting rod is designed and installed between the cam 15 and the ejector rod 5, and the leverage principle is used to reduce the requirement for the torque power of the servo motor. 14 moves down, the roller 14 on the other side moves up, and the ejector rod 5 moves upwards under the action of the connecting rod 19. The rod 5 moves down under the active force of the spring, and the impact block 11 collides with the test block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com