Reciprocating cutter

A technology of cutting tools and reciprocating rods, which is applied to manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve the problems of limiting the movement range of the guide wheel bracket, limiting the movement range of the guide wheel bracket, etc., and achieves flexible use and structure. Simple, compact and quick-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

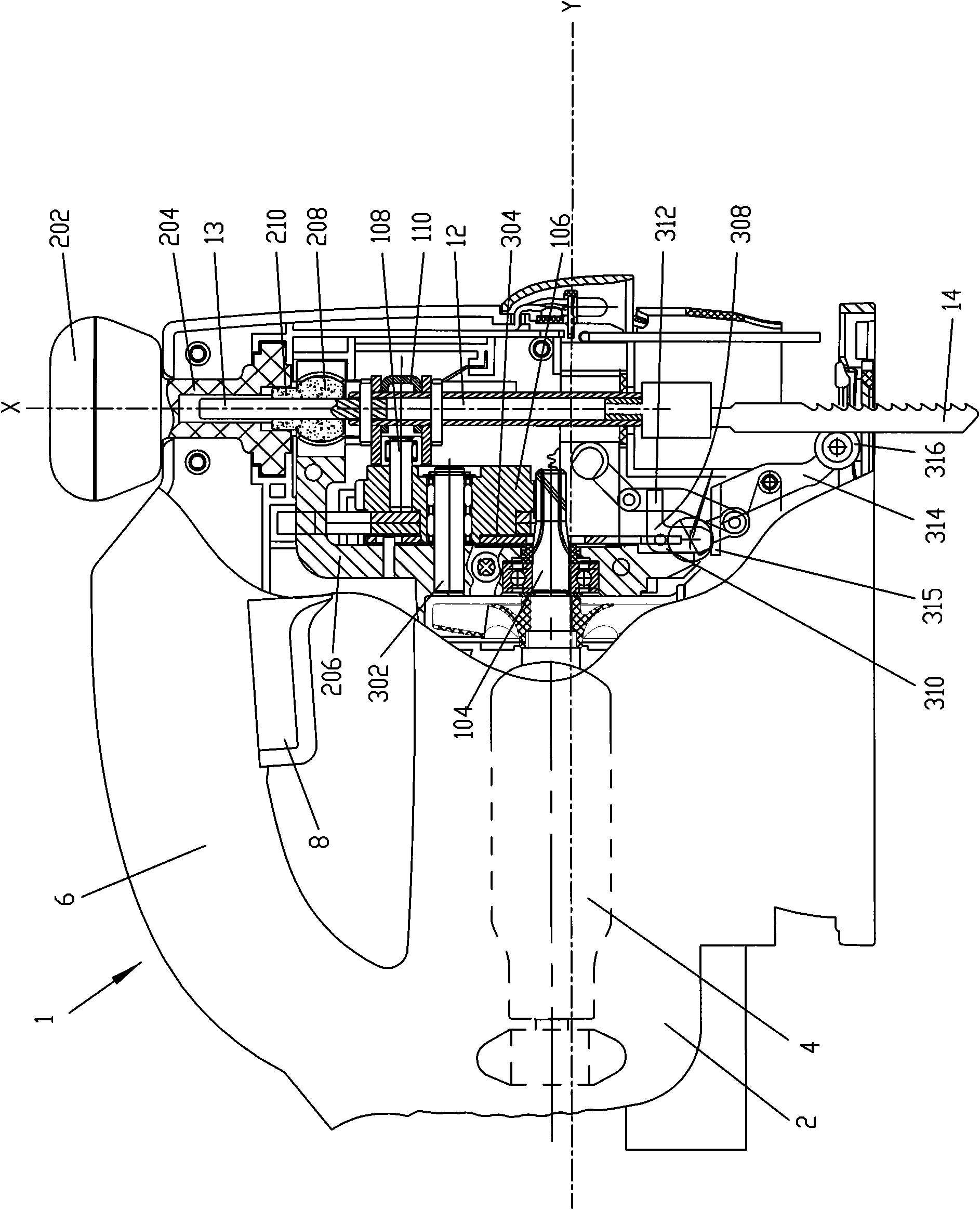

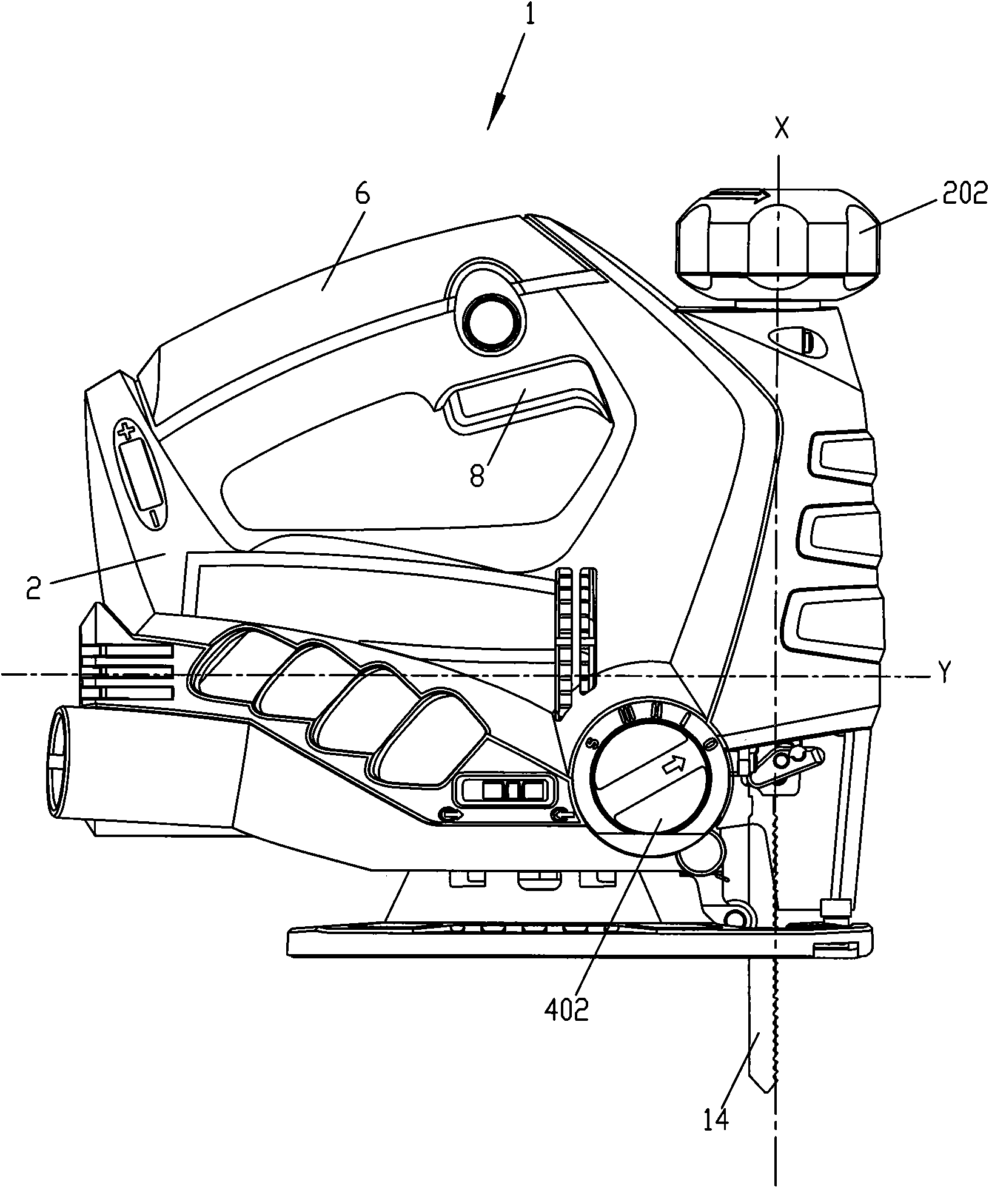

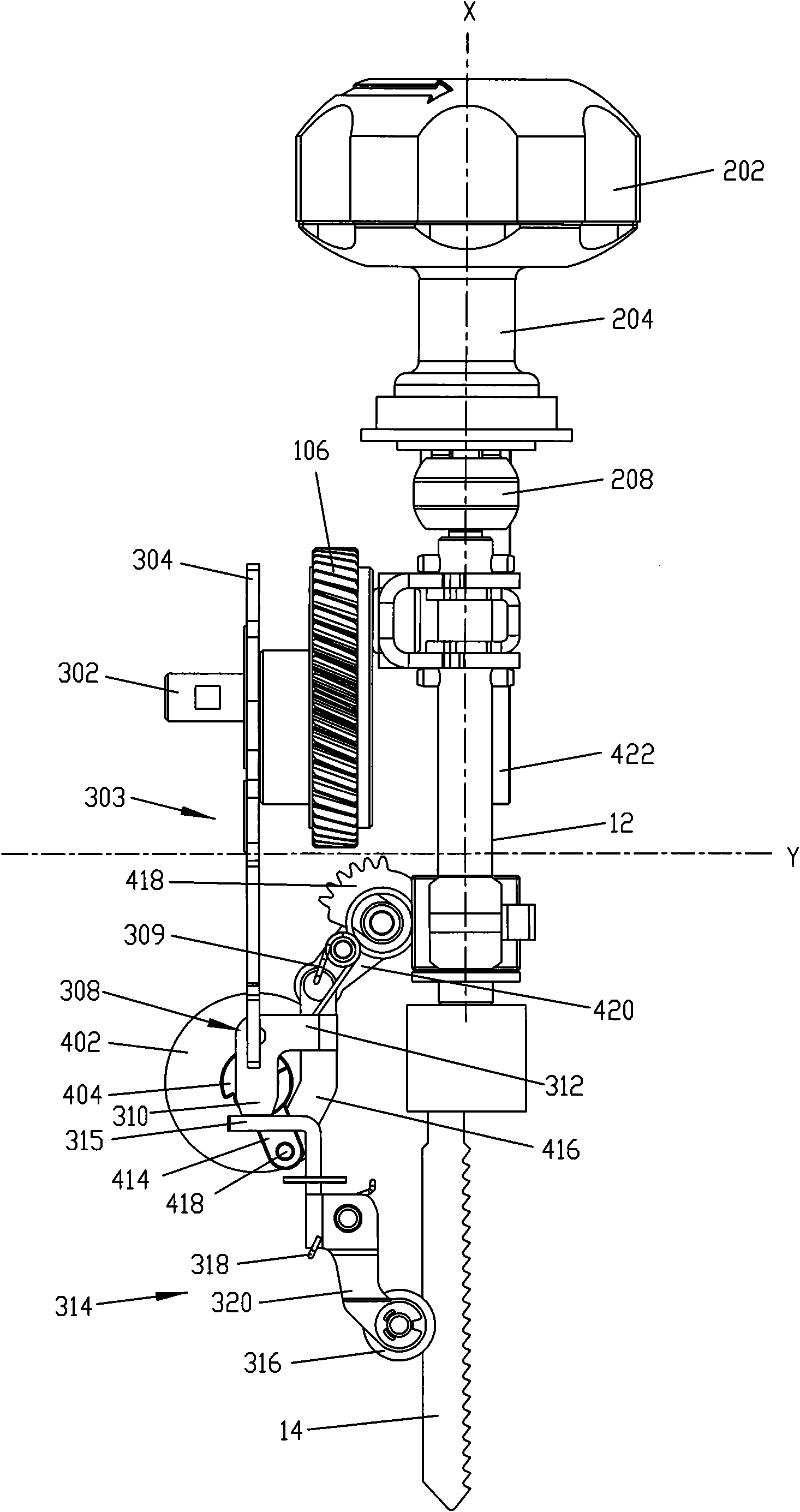

[0048] The preferred embodiment of the reciprocating cutting tool of the present invention is a jig saw. Such as figure 1 As shown, the left side of the jig saw 1 of this embodiment is defined as the rear of the jig saw 1, the right side is defined as the front, the upper side is defined as the upper side, and the lower side is defined as the lower side. The jig saw 1 has a reciprocating axis X extending in the up-down direction and a housing longitudinal axis Y extending in the front-rear direction, and the axis X and the axis Y are perpendicular to each other.

[0049] Such as figure 1 The jig saw 1 includes a housing 2, and a power source is fixedly arranged in the housing 2. In this embodiment, it is preferably a motor 4. The motor 4 is connected to and rotationally drives the main shaft 104. One end of the main shaft 104 is connected to the motor 4, and the other end A gear is formed, and the gear meshes with the outer peripheral surface of the large gear 106. The large gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com