Neoprene latex adhesive and preparation method thereof

A chloroprene latex and adhesive technology, applied in the direction of chloroprene adhesives, adhesives, adhesive types, etc., can solve the problem of not mentioning antifreeze performance and low temperature storage stability, difficult to use normally, unstable storage, etc. problems, to achieve the effect of improving antifreeze performance and low temperature storage stability, improving low temperature storage stability, and a wide range of low temperature applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

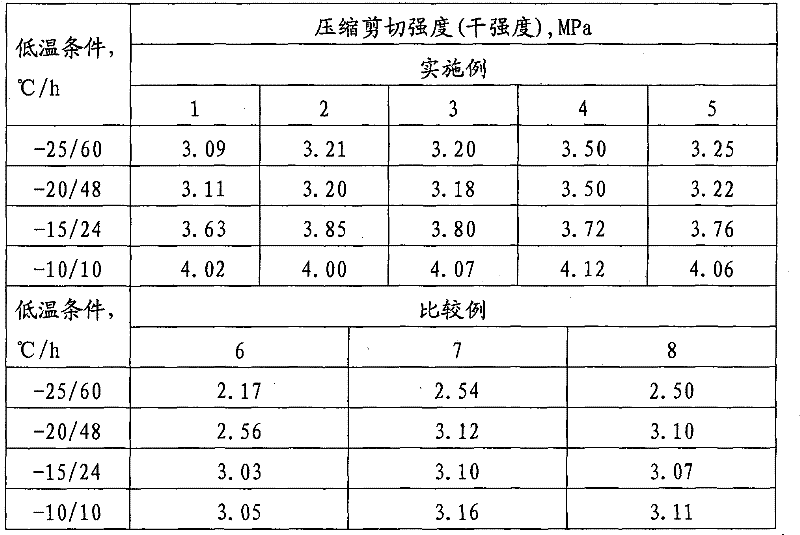

Embodiment 1

[0033] According to the formula weight ratio, 70 parts of neoprene latex CRL50G neoprene latex are added in the reactor, and at 300 rev / min rotating speed, disperse for 5 minutes; Add zinc oxide aqueous dispersion (proportion by weight: zinc oxide: Fatty acid polyoxyethylene methyl ether: soft water = 5: 3: 2, just mix and ball mill evenly) 6 parts, 2,6-di-tert-butyl p-cresol aqueous dispersion (proportion by weight: 2,6-di tert-butyl-p-cresol: fatty acid polyoxyethylene methyl ether: soft water=5:3:2, mix and ball mill evenly) 1.2 parts, compound antifreeze (proportioning by weight: sodium salicylate: leveling agent O: propylene glycol = 0.7: 0.3: 9, just mix well) 5 parts, dipropylene glycol monobutyl ether 0.39 part, under 500 rev / min rotating speeds, disperse for 30 minutes; Add tackifier (proportion by weight: two Toluene denatured resin NIKANOL L: rosin resin: fatty acid polyoxyethylene methyl ether: soft water = 2: 3: 3: 2, mixed and ball-milled evenly) 8 parts, acceler...

Embodiment 2

[0035] According to the proportioning by weight of the formula, 60 parts of neoprene latex CRL41I carboxylated neoprene latex are added in the reactor, and dispersed for 5 minutes at a speed of 300 rpm; : Alkyl polyglucoside: soft water=5:3:2, just mix and ball mill evenly) 5 parts, 2,6-di-tert-butyl p-cresol aqueous dispersion (proportioning by weight: 2,6-di-tert Butyl p-cresol: alkyl polyglucoside: soft water=5: 3: 2, mix and ball mill evenly) 1.2 parts, composite antifreeze (proportioning by weight: sodium salicylate: leveling agent O: propylene glycol =0.6:0.2:8, just mix evenly) 6 parts, 0.59 parts of dipropylene glycol monobutyl ether, at 500 rev / min rotating speed, disperse for 15 minutes; add tackifier (proportion by weight: xylene modified resin NIKANOL LL: rosin resin: alkyl polyglucoside: soft water = 1:4:3:2, just mix and ball mill evenly) 12 parts, water dispersion of accelerator (proportion by weight: ethylene thiourea: alkyl Polyglucoside: soft water = 5:3:2, ...

Embodiment 3

[0037] According to the formula weight ratio, 77 parts of neoprene latex CRL40G water-based neoprene latex are added to the reactor, and dispersed for 5 minutes at a speed of 300 rpm; zinc oxide aqueous dispersion is added (proportion by weight: Zinc oxide: N-alkylglucamide: soft water=5:3:2, just mix and ball mill evenly) 7 parts, 2,6-di-tert-butyl p-cresol water dispersion (proportion by weight: 2, 6-di-tert-butyl-p-cresol: N-alkylglucamide: soft water=5:3:2, mixed and ball milled evenly) 1.2 parts, compound antifreeze (proportioning by weight: sodium salicylate: Leveling agent O: propylene glycol = 1: 1: 8, just mix evenly) 6 parts, dipropylene glycol monobutyl ether 0.19 parts, disperse for 25 minutes at a speed of 500 rpm; Ratio: xylene denatured resin NIKANOL L: rosin resin: N-alkylglucamide: soft water = 4: 1: 3: 2, mixed and ball milled evenly) 6 parts, accelerator water dispersion (proportioning by weight: N, N-ethylphenyl zinc dithiocarbamate: N-alkylglucamide: soft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com