Transmission

A transmission and force technology, applied in friction transmission, belts/chains/gears, mechanical equipment, etc., can solve the problems of incompatibility of end cams, insufficient pressing force, excessive pressing force, etc. Insufficient pressure, low number of parts, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] First, the configuration will be described.

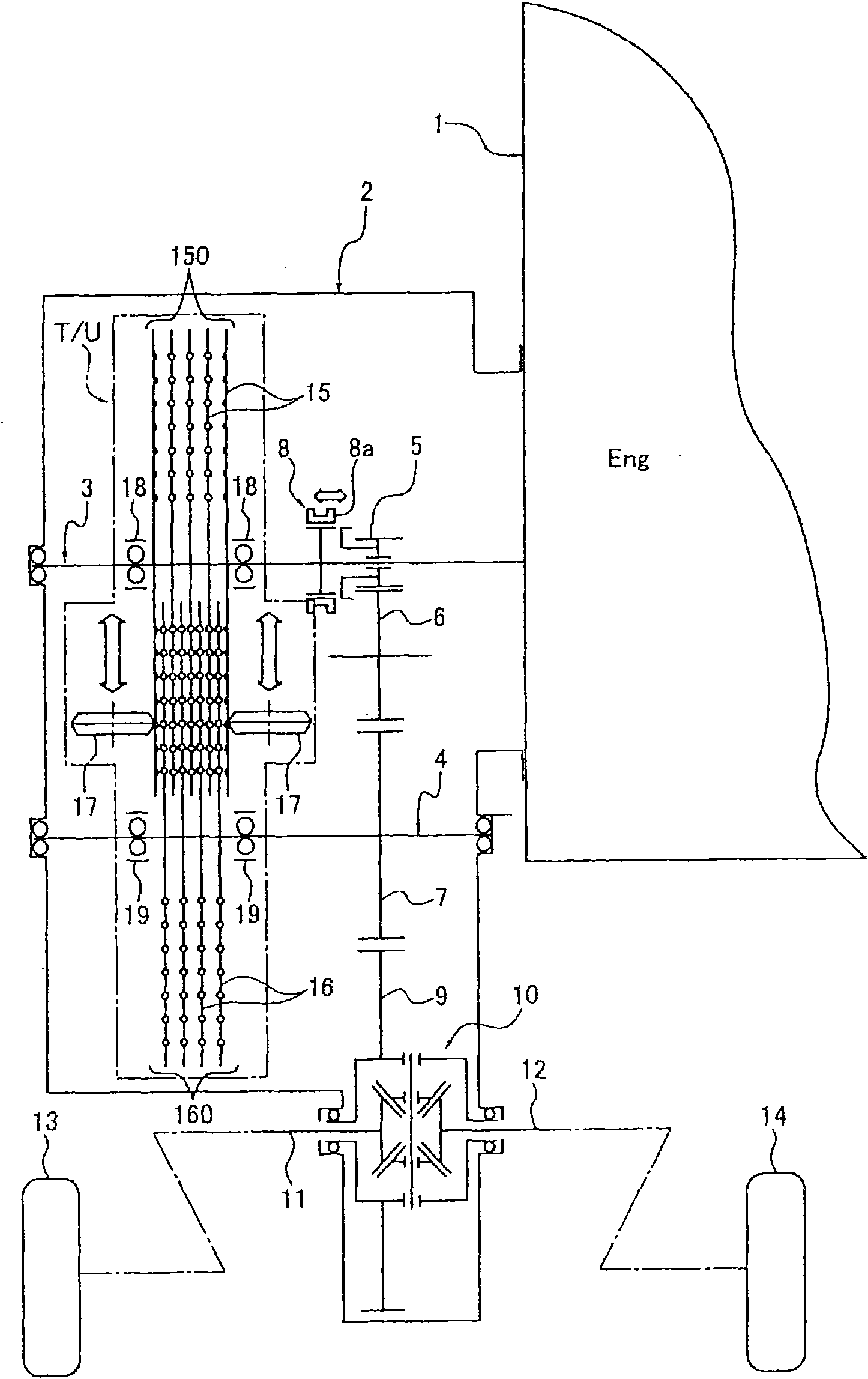

[0063] figure 1 It is an overall schematic diagram showing the automatic transmission system for a vehicle to which the multi-disk multi-stage transmission unit T / U (an example of the transmission) of the first embodiment is applied.

[0064] The automatic transmission system for vehicles that has been applied to the multi-disk multi-stage transmission unit T / U of embodiment 1 is as follows: figure 1 As shown, it has: engine 1 (prime mover), transmission case 2, input shaft 3, multi-disk multi-stage transmission unit T / U, output shaft 4, reverse gear 5, reverse intermediate gear 6, output gear 7, synchronous Mechanism 8, final reducer 9, differential gear unit 10, left and right drive shafts 11, 12, left and right drive wheels 13, 14.

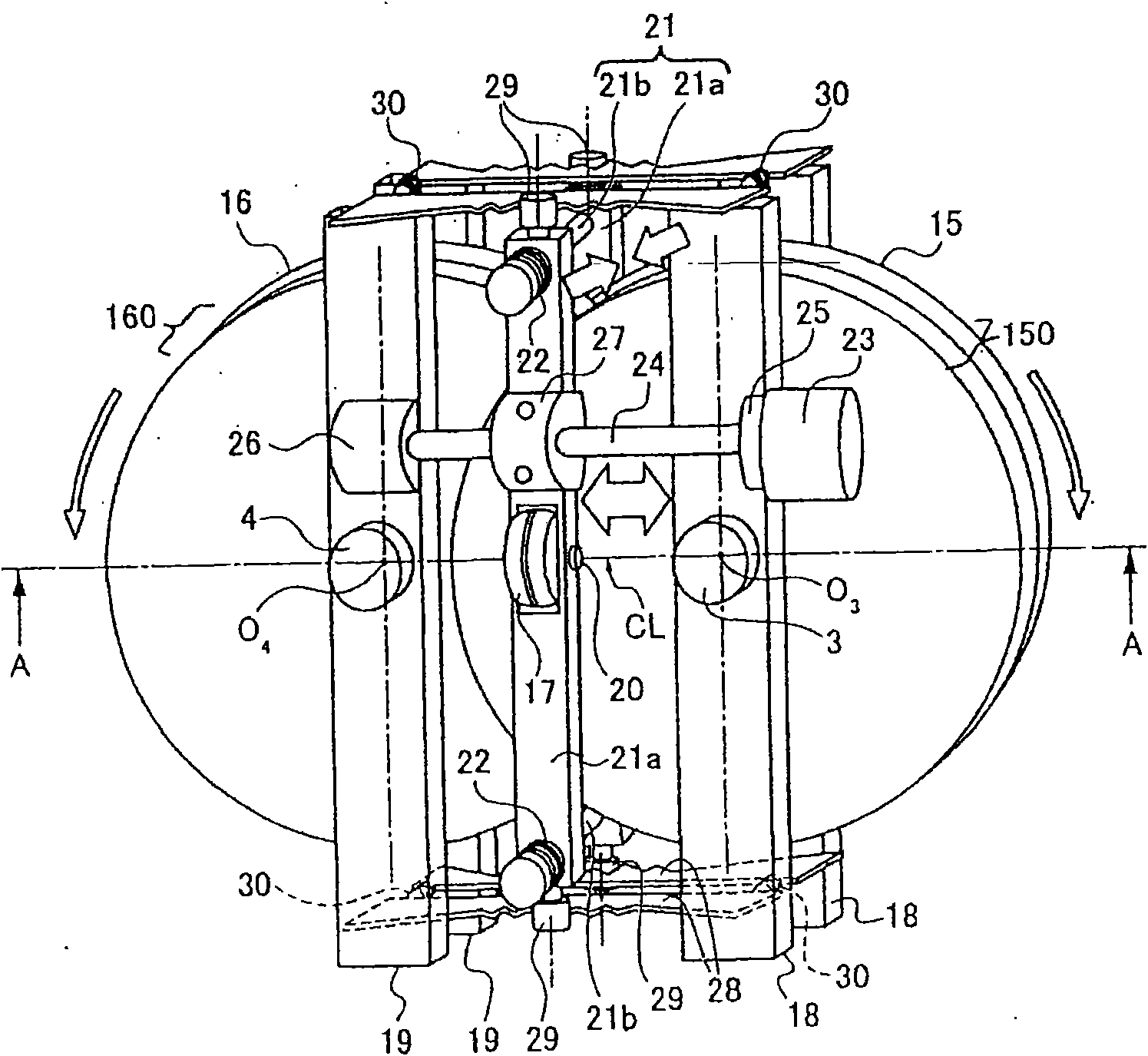

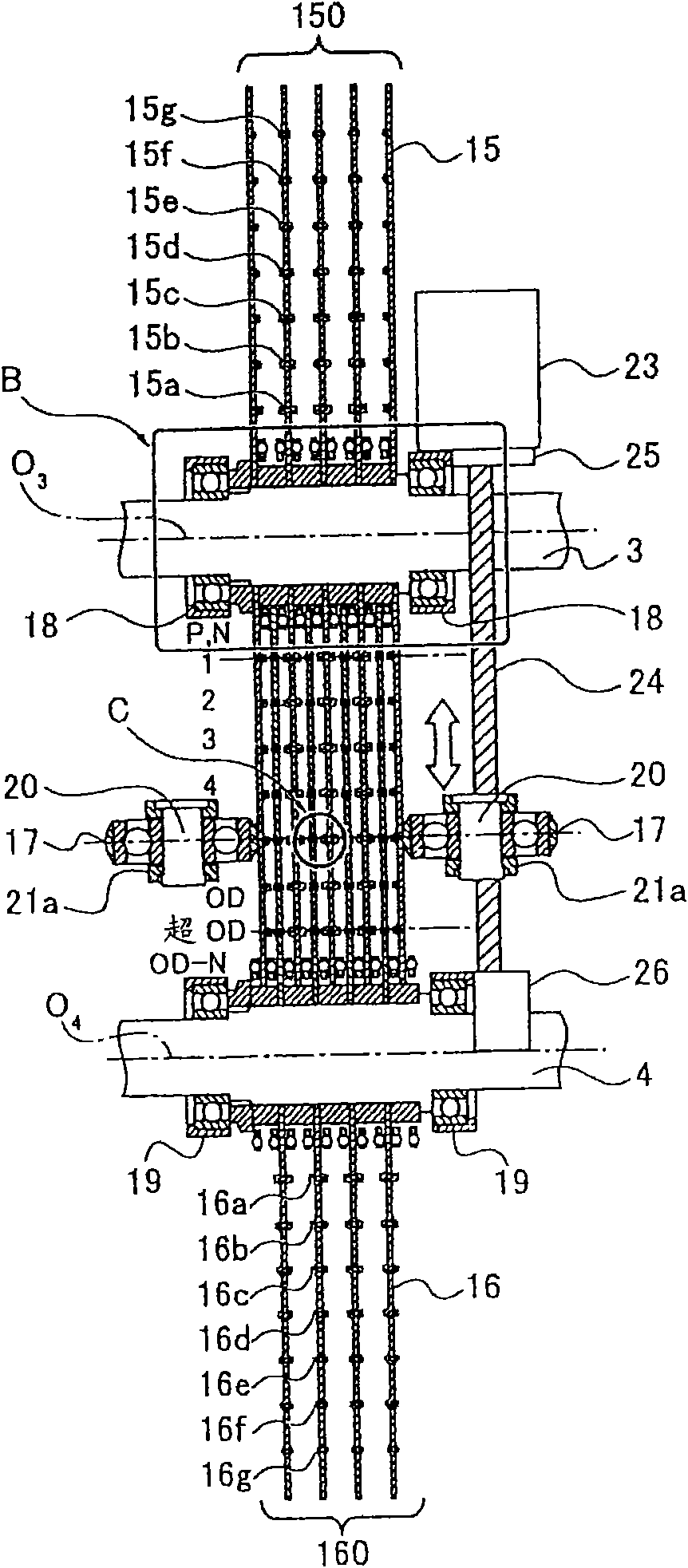

[0065] The above-mentioned multi-disk multi-stage transmission unit T / U has: a main disc group 150 composed of a plurality of input discs 15, a sub-disc group 160 composed of a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com