Heating cooking device

A cooker and heater technology, which is applied to electric heating fuels, lighting and heating equipment, heating fuels, etc., can solve the problems of inability to obtain, non-uniform hot air circulation, and inability to prevent water droplets, and achieves the promotion of homogenization, Seeking the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

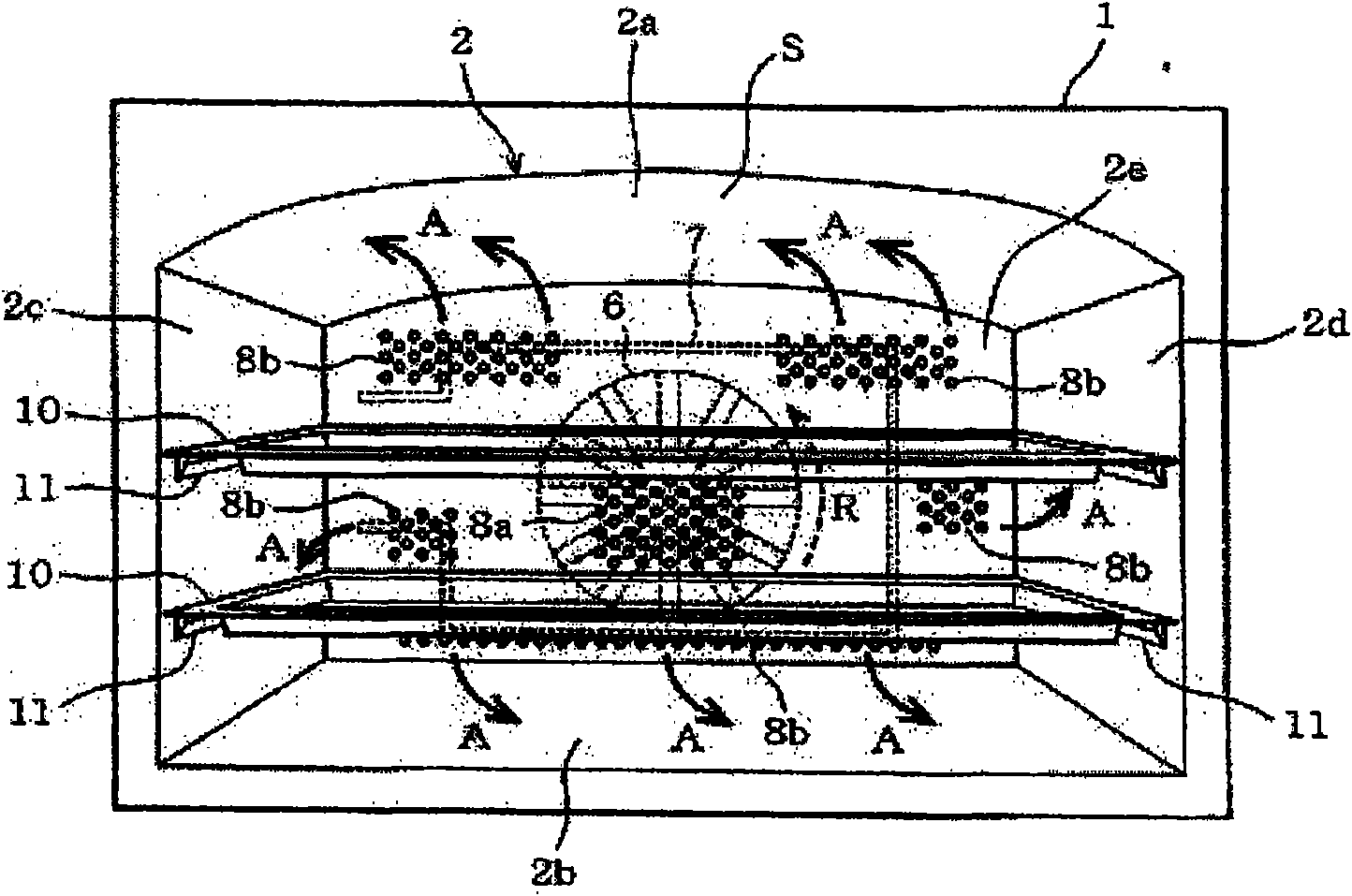

[0050] Hereinafter, refer to the description of the first embodiment of the present invention Figure 1 to Figure 3 Be explained.

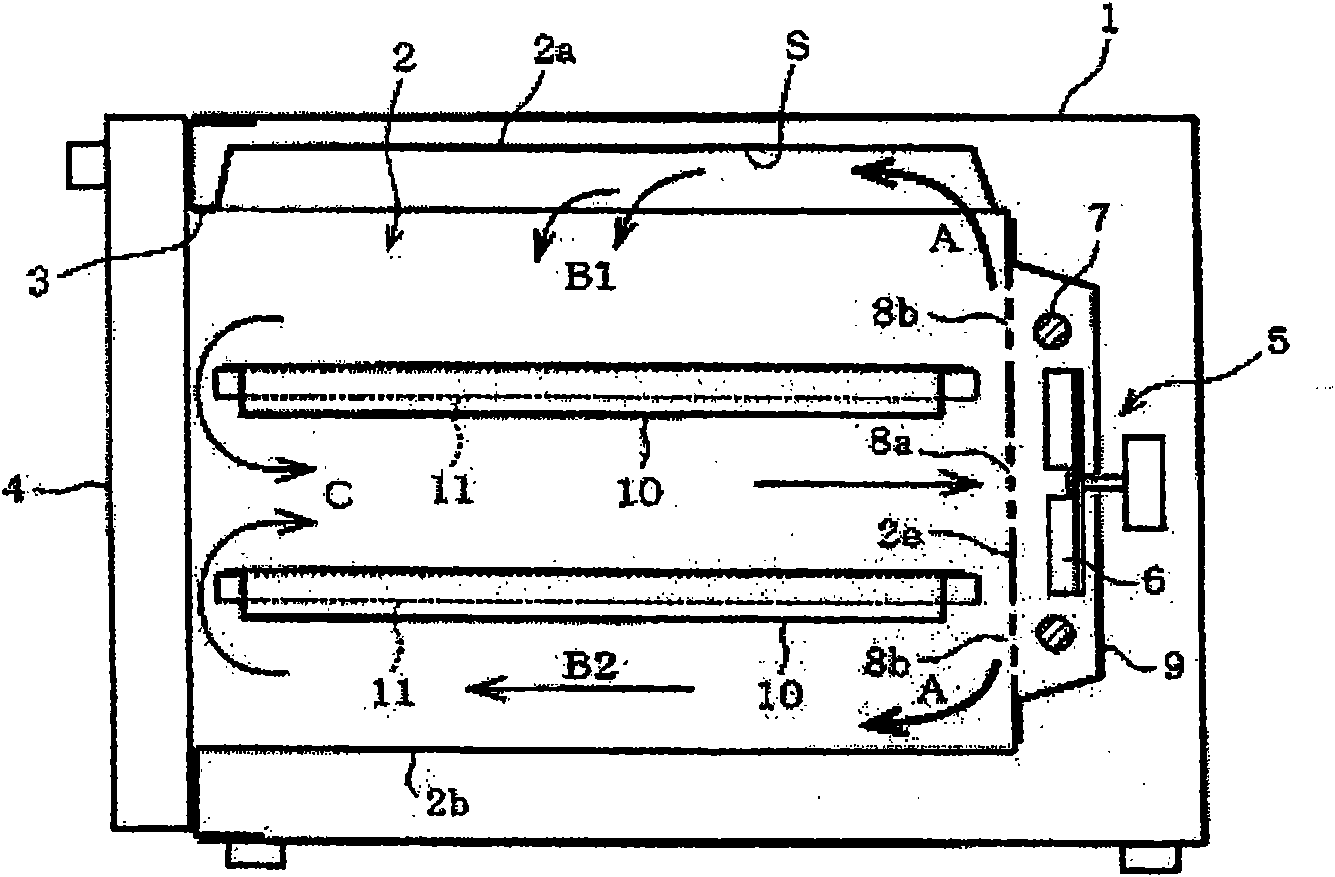

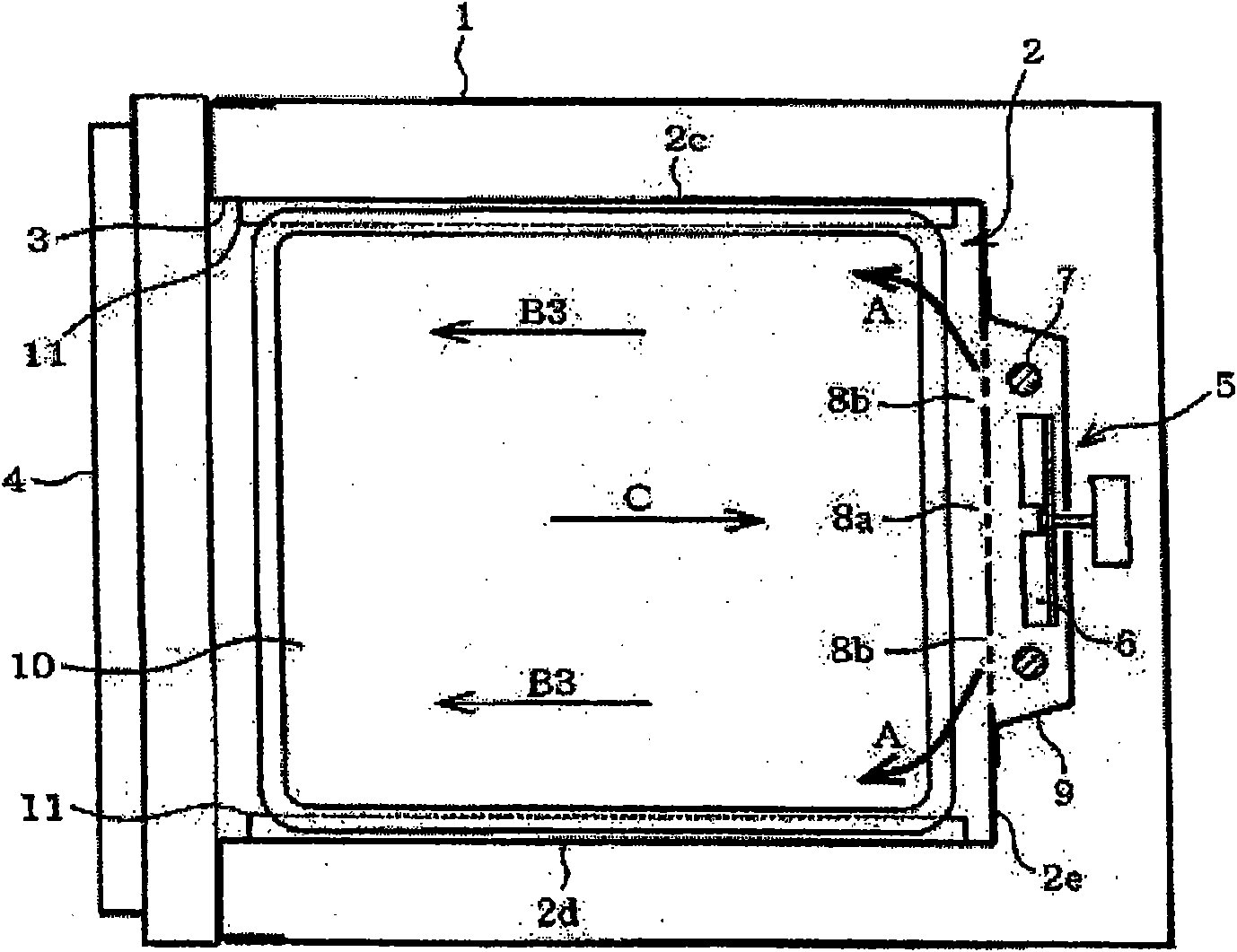

[0051] figure 1 It is the front view of the heating cooker in the state that took off the front door, figure 2 It is a longitudinal sectional side view showing the cross-sectional structure of the substantially central part except the door, image 3 Similarly, it is a cross-sectional plan view which shows the cross-sectional structure of the substantially central part except a door, and demonstrates the whole result of a heating cooker based on these figures.

[0052] In the inside of the rectangular box-shaped housing 1 that forms the outer contour, an open front, that is, a box-shaped oven box body 2 is provided on the front surface, and the front surface opening 3 is opened and closed in a rotatable manner. Door 4. In addition, as the peripheral wall forming the oven box body 2, it includes a top wall 2a, a bottom wall 2b, a left side wall...

no. 2 approach

[0095] With respect to above-mentioned embodiment, Figure 6 to Figure 10 The second embodiment of the present invention is shown, and the parts substantially the same as those of the above-mentioned first embodiment are given the same reference numerals and their descriptions are omitted, and the different points will be described.

[0096] Figure 6 It shows the longitudinal section front view structure of the plane heater and the heater platen, Figure 7 It is figure showing heating cooker which omitted door from front view, Figure 8 The longitudinal section side structure of the heating cooker 1 is shown. Figure 9 It is a figure which shows the 2nd embodiment of the heating cooker which has the surface heater effective for grill cooking, Figure 10 It is a perspective view of a flat heater platen.

[0097] Collar parts (flange parts) 21a and 21b are formed on the left and right side walls 2c and 2d upper ends of the oven box 2, and flange parts 22a and 22b are also f...

no. 3 approach

[0114] With respect to above-mentioned embodiment, Figure 11 to Figure 14The third embodiment of the present invention is shown, and the parts substantially the same as those of the above-mentioned first embodiment are given the same reference numerals and their explanations are omitted, and the different points will be described.

[0115] Figure 11 , 12 A third embodiment of a heating cooker having a flat heater 14 effective for roasting and cooking is shown, wherein, Figure 11 It is a longitudinal front view showing the schematic structure of the heating cooker; Figure 12 It is an external perspective view of the oven body 2 viewed from above.

[0116] The above-mentioned planar heater 14 is generally provided on the outer wall surface side of the top wall 2a in a closely adhered state. Therefore, in order to form it into a flat shape, for example, a coil for a heater is wound on a flat mica plate and sandwiched from both surfaces by the mica plate.

[0117] However...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com