Method and device for testing gelation time of electrolyte colloid

A technology of gel time and testing device, which is applied in the direction of electrical unknown time interval measurement, device for measuring time interval, measuring device, etc. It can solve the problems of battery utilization rate drop, discharge performance drop, colloid condensation, etc., and achieve simple test process Convenience, accurate and stable results, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

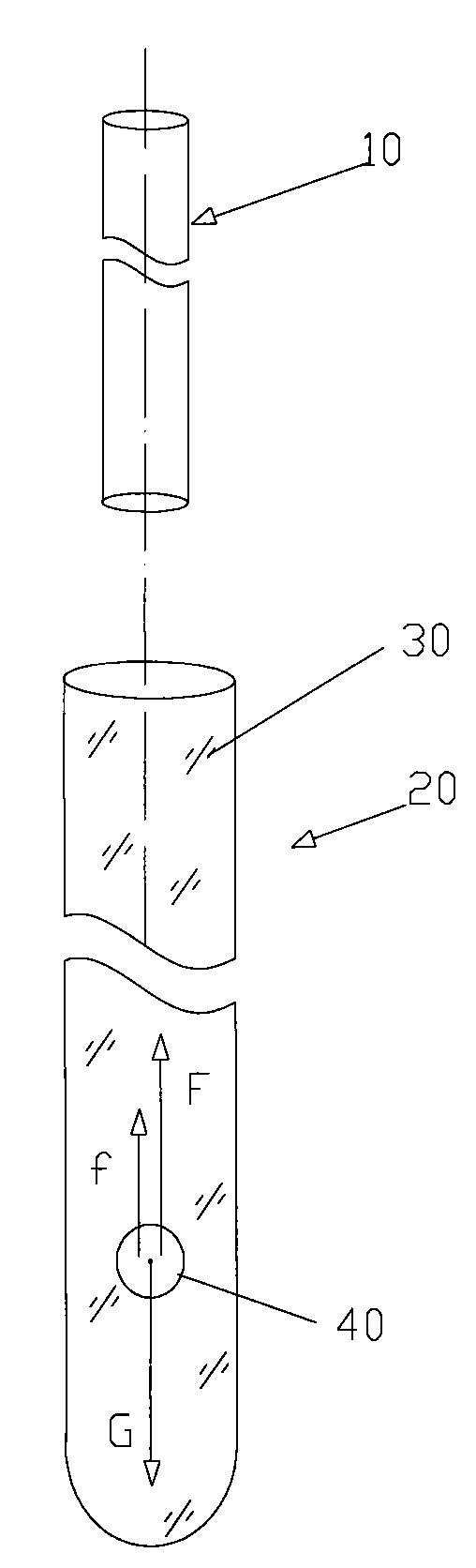

[0011] Hereinafter, the present invention will be further described in detail through specific embodiments in conjunction with the drawings.

[0012] The invention relates to a method for testing the gel time of electrolyte colloids and related devices.

[0013] The electrolyte colloid of the colloidal battery is generally mixed with a gelling agent such as silica and a stabilizer and dispersant in a sulfuric acid solution, stirred, poured into the electrode box and solidified into a colloid. Therefore, the gel battery has the advantages of no electrolyte flow, no acid leakage, less free discharge, and long battery life. Because of the different electrolyte formulations of gel batteries, the gel time of the corresponding electrolyte colloids is also different.

[0014] The gel time of the electrolyte gel is very important for the packaging of gel batteries. When there is no gel time as a reference to encapsulate the battery, the problem of midway gel is prone to occur, that is, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com