Transmission hole of matched high frequency broadband impedance

A technology of impedance matching and transmission holes, which is applied in the field of transmission holes, can solve the problems of reducing the flexibility of circuit applications and the difficulty of controlling the precision of the overall multi-layer printed circuit board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

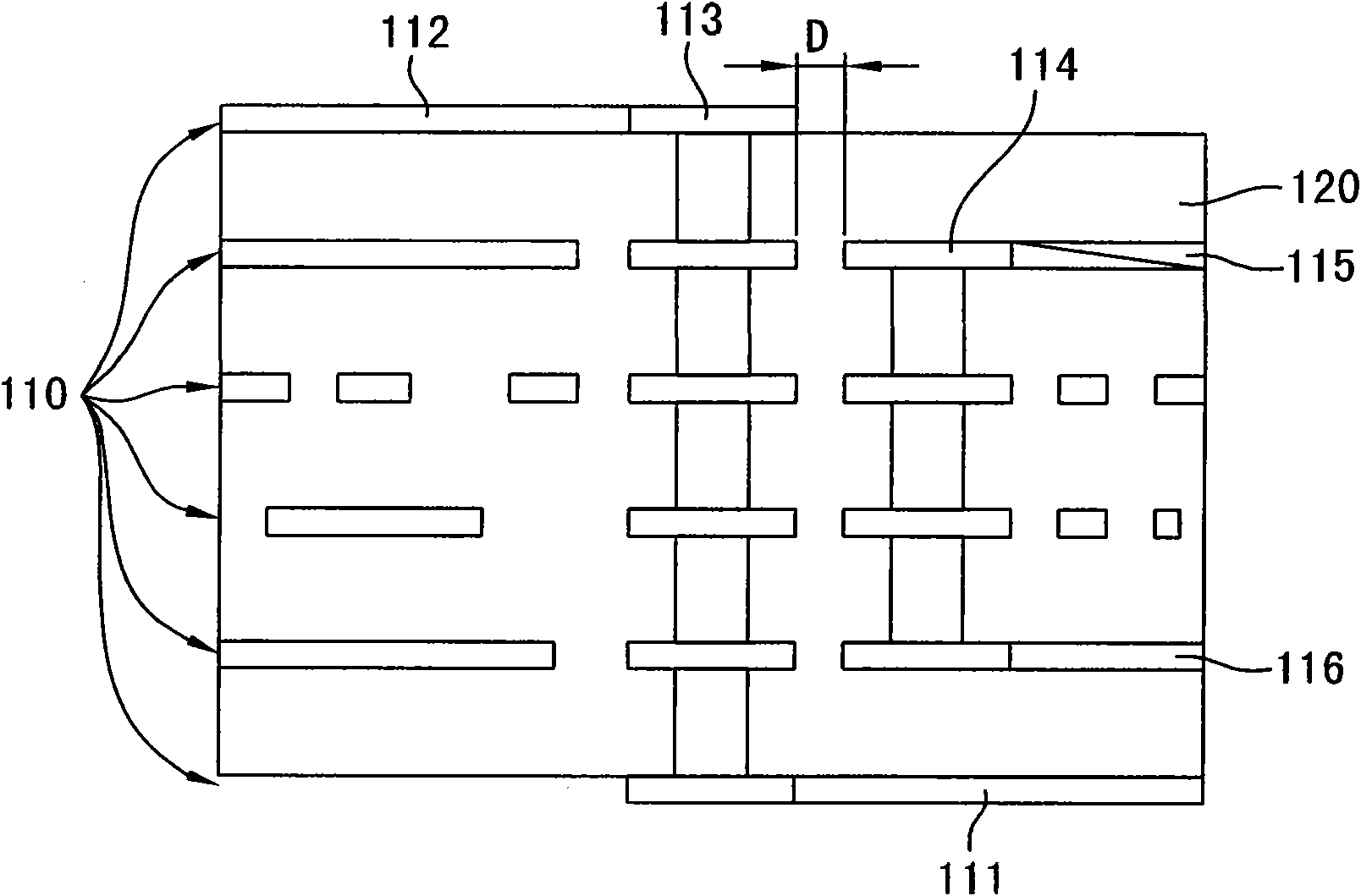

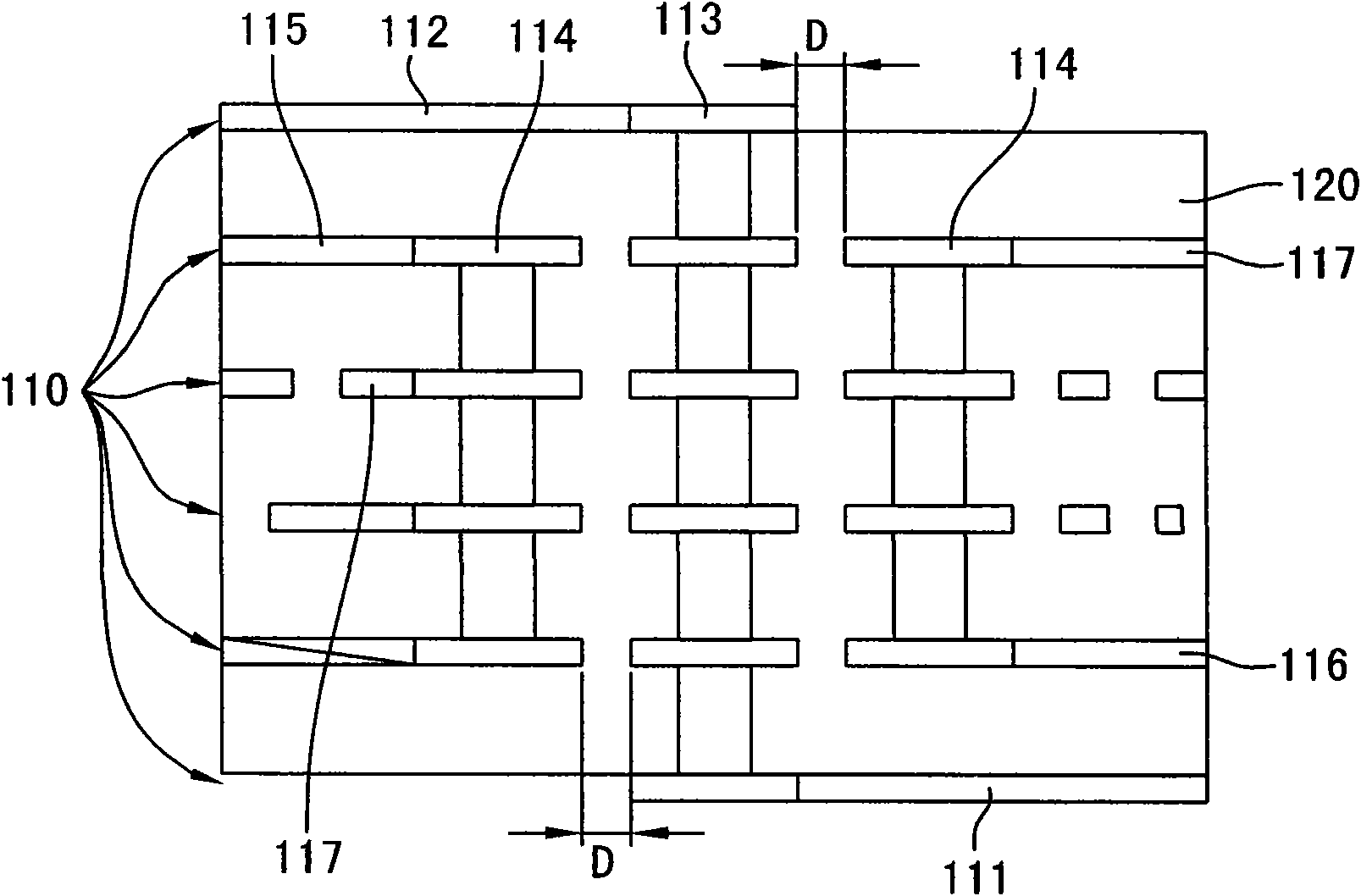

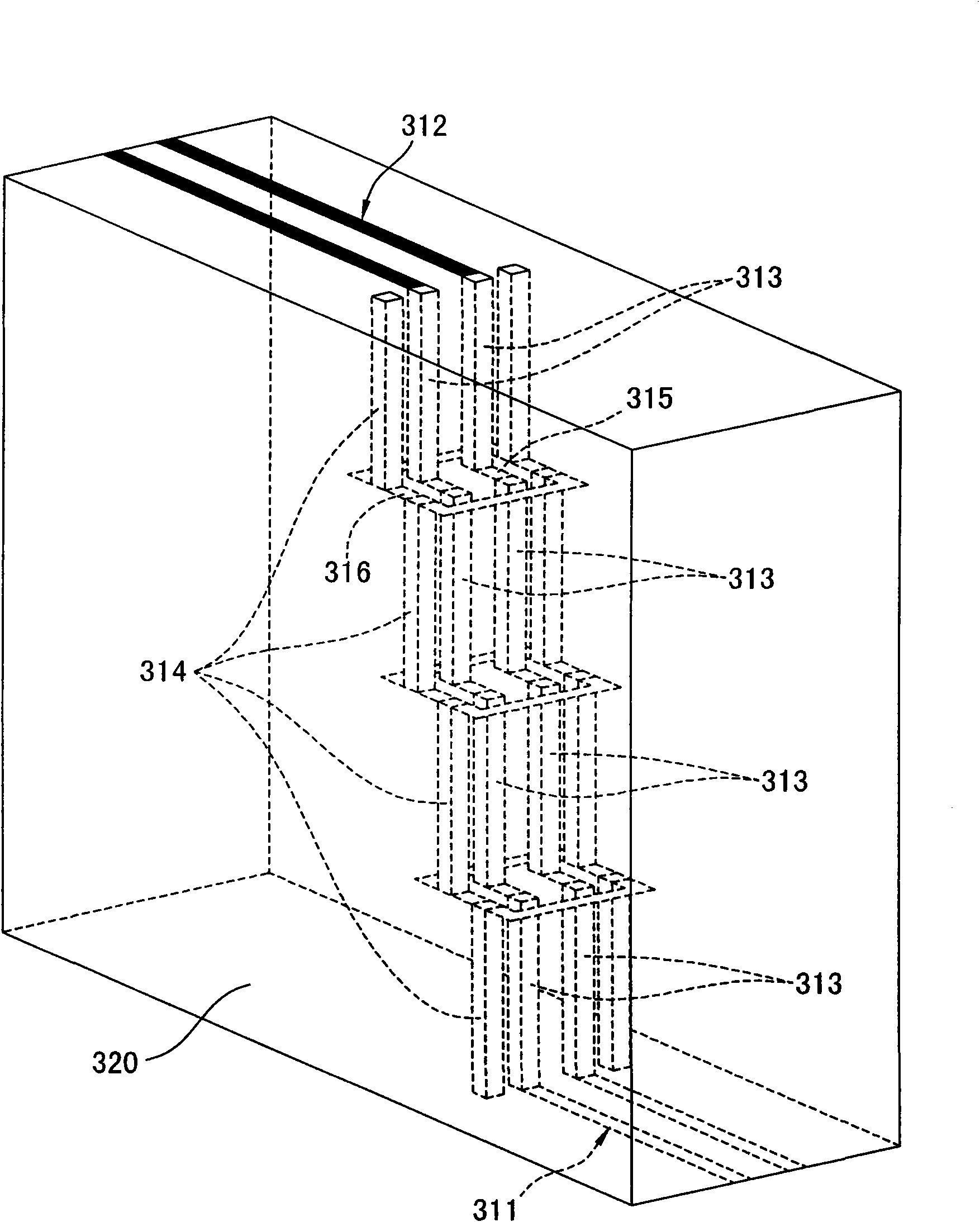

[0046] The high-frequency broadband impedance matching transmission hole disclosed by the present invention is applied to various substrates, such as multi-layer circuit boards, LTCC, IC, thick-film ceramics, thin-film ceramics, silicon substrate glass substrate manufacturing processes, etc., through the grounding via hole It is arranged around the signal via hole, so that the signal transmission of the vertical signal via hole has impedance matching. The following structure takes a multilayer circuit board as an example, and the multilayer circuit board achieves the purpose of impedance matching through structural design. The multi-layer circuit board structure is a combination of stacking multiple insulating layers and circuit layers, using vertical signal via holes to provide electrical connections to the circuit layers, and adding vertical ground via holes to the structure, so that the vertical signal via holes The signal transmission achieves impedance matching, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com