Extraction separator and manufacturing method thereof

A manufacturing method and separator technology, applied in separation methods, chemical instruments and methods, solvent extraction, etc., can solve the problems of unsatisfactory use of extraction separators, affecting the extraction capacity of supercritical extraction devices, and the decrease in the purity of process media, etc. To achieve the effect of ensuring normal working life, maintaining extraction capacity and high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

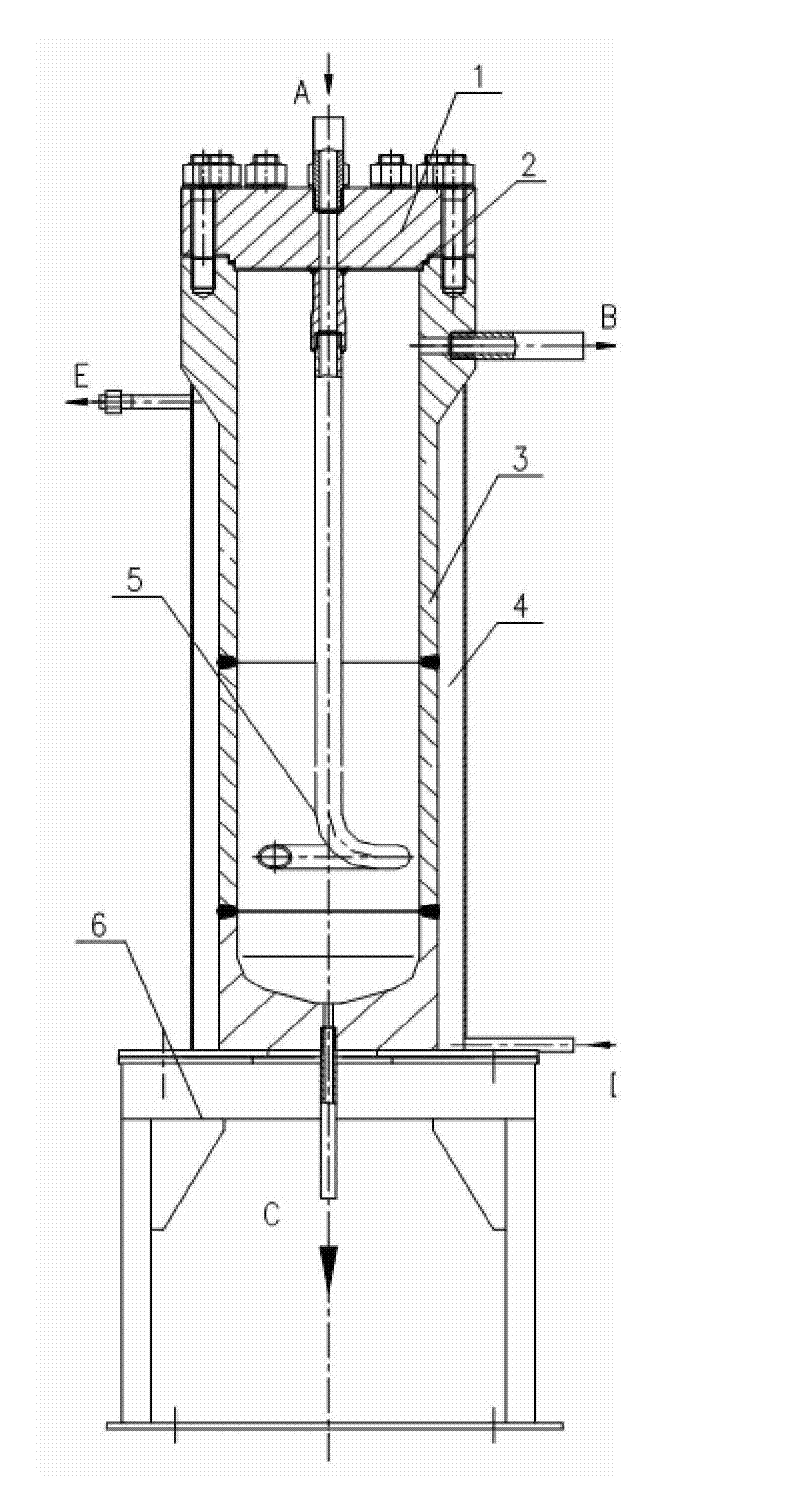

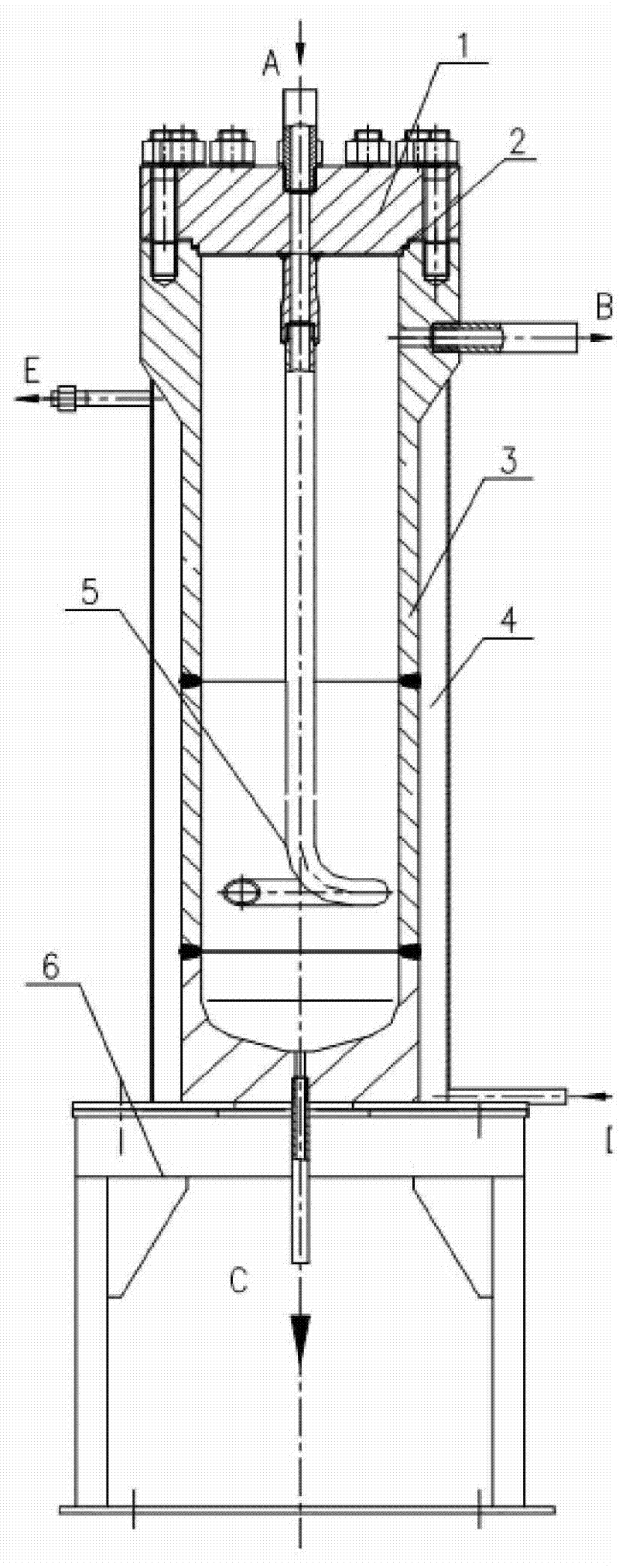

[0014] Embodiment of the present invention: when making the extraction separator, it is manufactured according to the method of the present invention, that is, the process medium enters the extraction separator through the air flow guide pipe by setting an air flow guide pipe at the process medium inlet of the extraction separator The flow direction is changed after the inner cavity of the autoclave, and the process medium flows along the circumferential direction of the inner cavity of the autoclave and ejects the air flow guide pipe along the tangential direction of the circumference.

[0015] When specifically making the extraction separator according to the method of the present invention, its structure is as follows figure 1 As shown, the structure of the top cover 1, the autoclave body 3 and the separator support 6 can be made in a conventional manner, and the top cover 1 is covered on the upper port of the autoclave body 3 and connected to the autoclave body 3 by bolts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com