Cooling wall combining steel plates and spherical graphite cast iron and manufacturing method thereof

A technology of nodular cast iron and a manufacturing method, which is applied in the field of metallurgical casting, can solve the problems of easy deformation of large flat steel plates, melt-through of cooling pipes, generation of cold partitions, etc., and achieves thin cooling wall thickness, improved service cycle, and good high temperature resistance performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

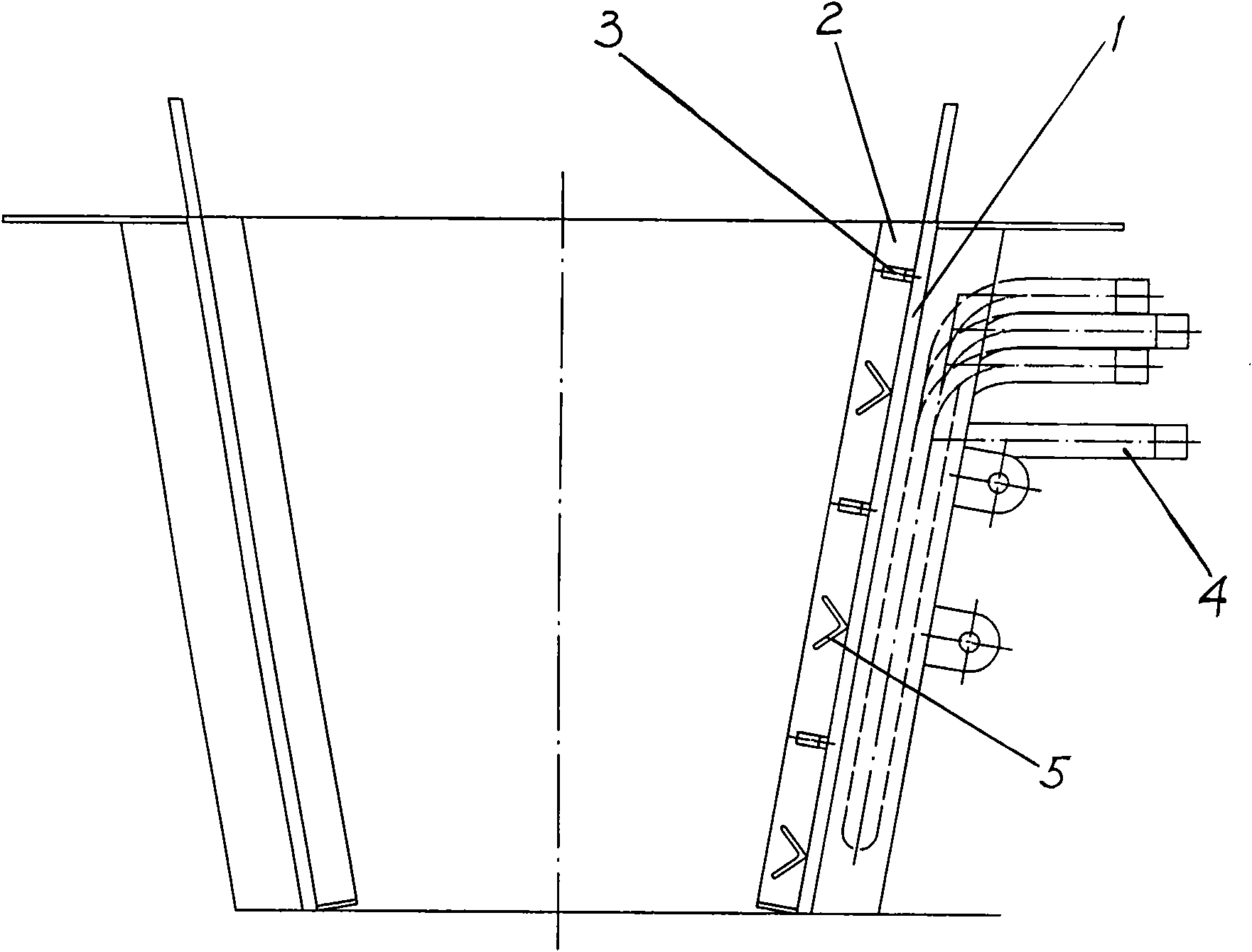

[0026] see Figure 1 to Figure 3 According to the present invention, a stave combining steel plate and ductile iron comprises a steel plate 1 and a ductile iron body 2, and the steel plate 1 and the ductile iron body 2 are composited.

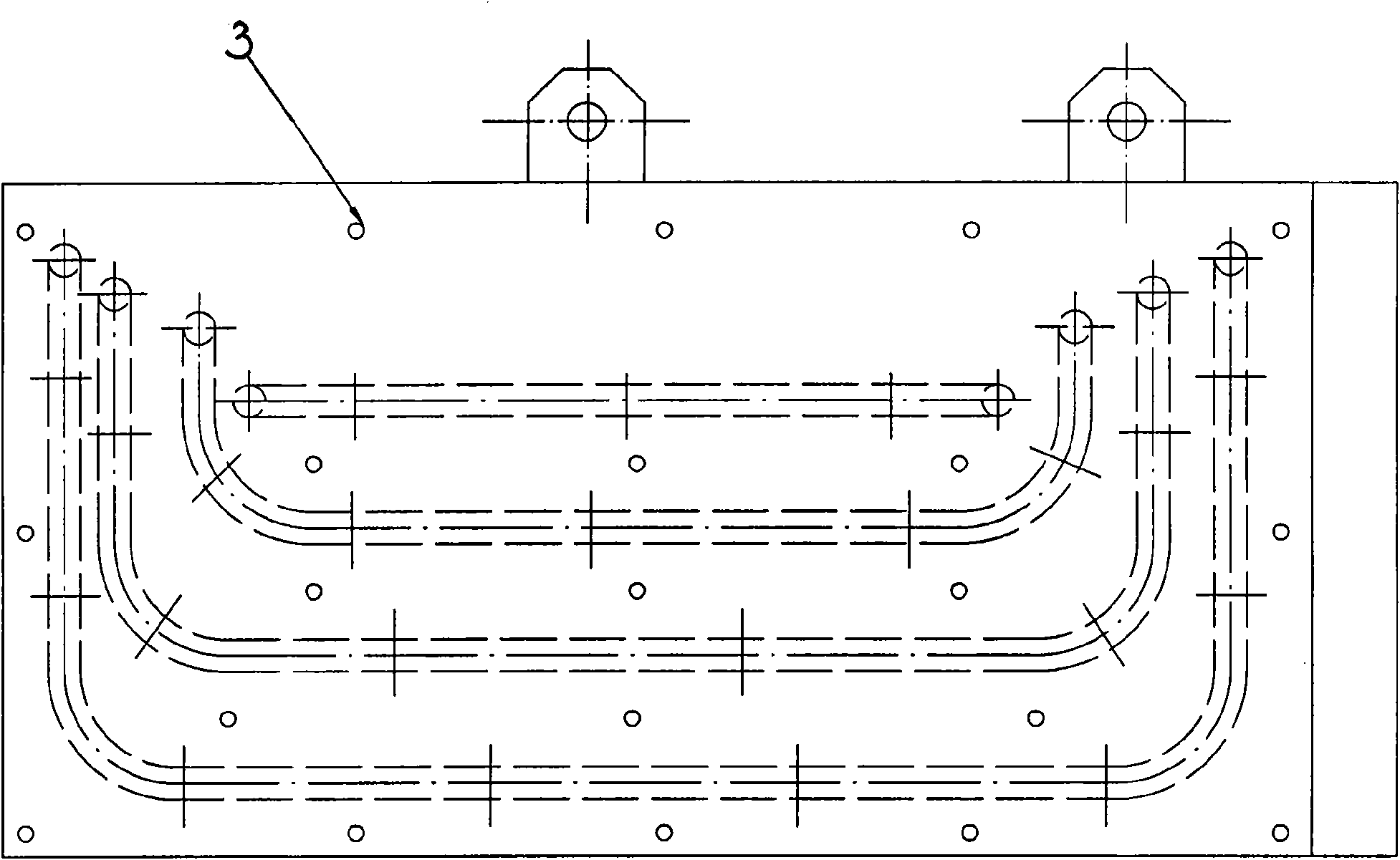

[0027] Several bolts 3 are cast into the ductile iron body 2 , and screw holes corresponding to the bolts 3 are provided on the steel plate 1 on its bottom and side surfaces. A layer of heat-conducting material is coated on the ductile iron body 2 . The nodular cast iron body 2 is combined with the steel plate 1 and fastened by several bolts 3 and nuts, so that the nodular cast iron body and the steel plate are integrated.

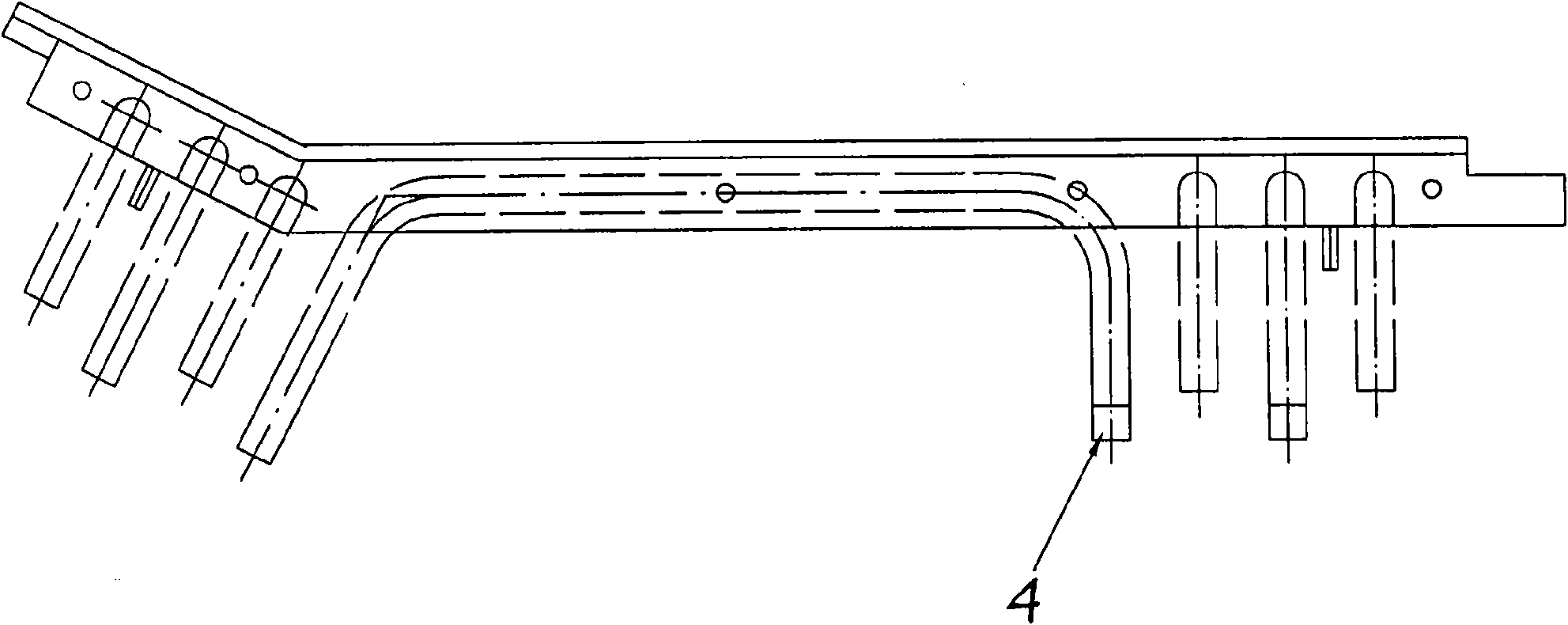

[0028] Several cooling pipes 4 are cast in the composite body of the ductile iron and the steel plate, and the cooling liquid circulates in the cooling pipes to cool the cooling wall. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap