Multilayer diamond brazing body and manufacturing method thereof

A diamond and brazing technology, applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., to achieve the effect of stable product quality and stable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

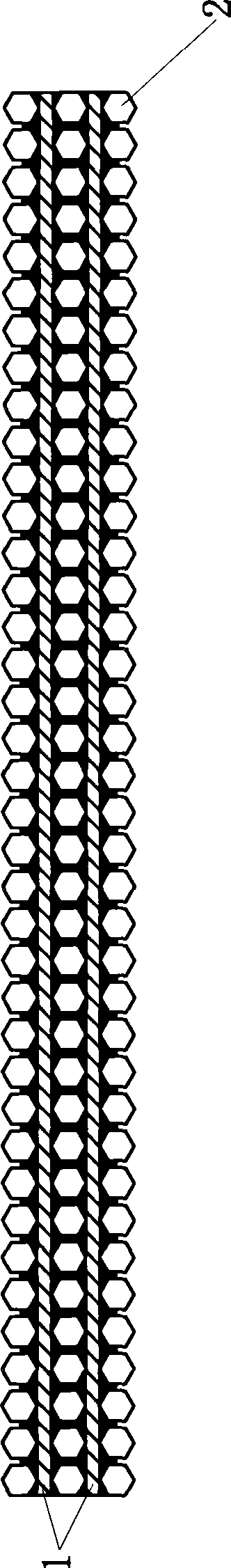

[0032] Such as figure 1 As shown, take two copper thin plates 1 with a thickness of 0.1mm, and uniformly coat the above-mentioned brazing material on both sides of each piece, the thickness of the brazing material layer is 0.5mm, and arrange diamonds Abrasive grains 2, diamond abrasive grains 2 are arranged outside the other sheet. The above-mentioned red copper sheet is superimposed, such as figure 1 As shown, a 2-layer superimposed body is obtained, and the two sides of the superimposed body are fixed with splints or molds. During the whole brazing process, a certain degree of pressure (3kg / cm2) is given to the superimposed body with splints or molds 2 ), so that on the one hand, it can prevent the warping of the superimposed body, and on the other hand, it can keep each layer of the superimposed body in close contact; then put it into a vacuum brazing furnace, vacuumize and heat according to the procedure, and braze After all the materials are melted, they are cooled with...

Embodiment 2

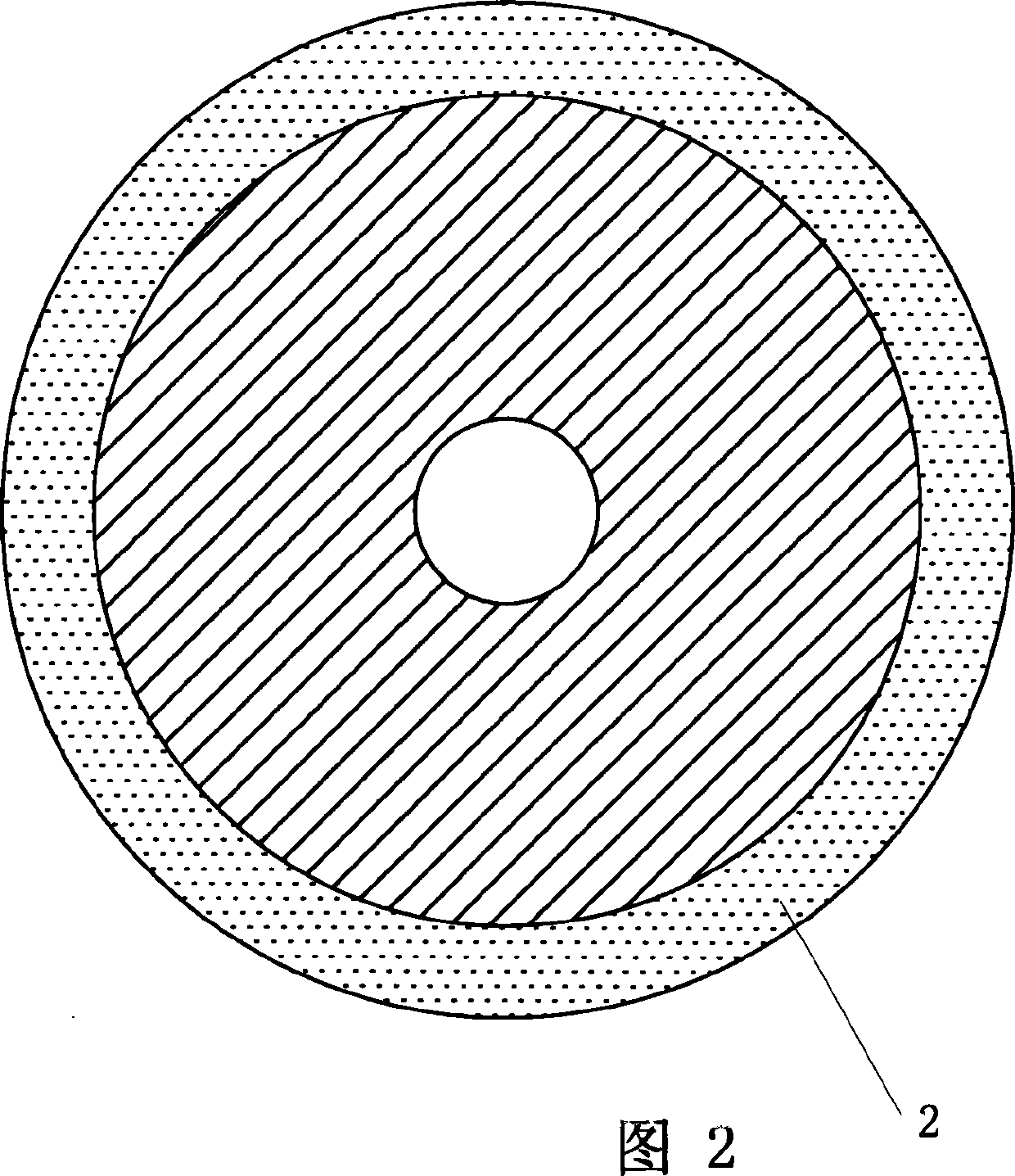

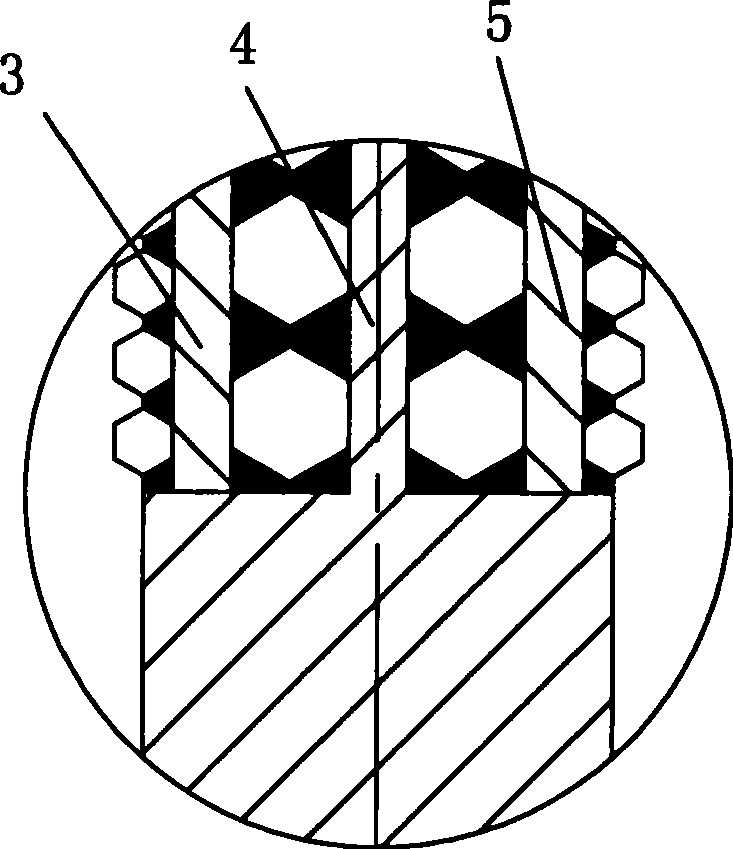

[0036] Such as figure 2 , image 3 and Figure 4 As shown, diamond multi-layer brazing and lateral cutting are applied as a preferred embodiment of the present invention. Two circular red copper sheets 3,5 with a thickness of 0.1mm are used as substrates, and on both sides of the red copper sheets 3,5 The side surface is coated with the above-mentioned brazing material, the thickness of the brazing material layer is 0.5mm, and the diamond abrasive grains 2 are arranged on the outer surface; a flange is processed on the ring matrix 4 in the middle, and the both sides of the flange are coated with The brazing material and the diamonds are placed in a row, and then the annular red copper sheet and the substrate are superimposed in the order of 3, 4, and 5. The annular red copper sheet 3 and 5 are distributed on both sides of the flange of the substrate 4, and the annular The annular ring surfaces of the red copper sheets 3 and 5 are matched with the flange surface of the matri...

Embodiment 3

[0040] refer to Figure 5 and Figure 6 Shown, this is an example of a diamond multi-layer brazing, face-cutting application. The difference from Example 2 is that the metal base 7 is made of steel, and another 12 copper sheets 1 with a thickness of 0.1 mm are used as the base. Apply the above brazing material, the thickness of the brazing material layer is 0.5mm, according to the needs of the proposed block, place diamond abrasive grains 2 on the side of the metal substrate 7 close to the copper sheet and on both sides of the copper sheet, and then place the diamond abrasive grains on the metal substrate 7 The above-mentioned red copper thin plates are stacked in sequence, and the two sides of the superimposed body are fixed with splints or molds and then put into a vacuum brazing furnace. During the whole brazing process, a certain degree of pressure (10kg / cm 2 ), the metal substrate 7, the copper sheet 1 and the diamond abrasive grains 2 can be tightly brazed together. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com