Method for cooling and sizing plastic profiles and device for realizing same

A technology for plastic profiles and plastics is applied in the field of devices for realizing the method, which can solve the problems of poor cooling and shaping effect, low production effect and high investment cost, and achieve the effects of good heat dissipation effect, convenient processing and high cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

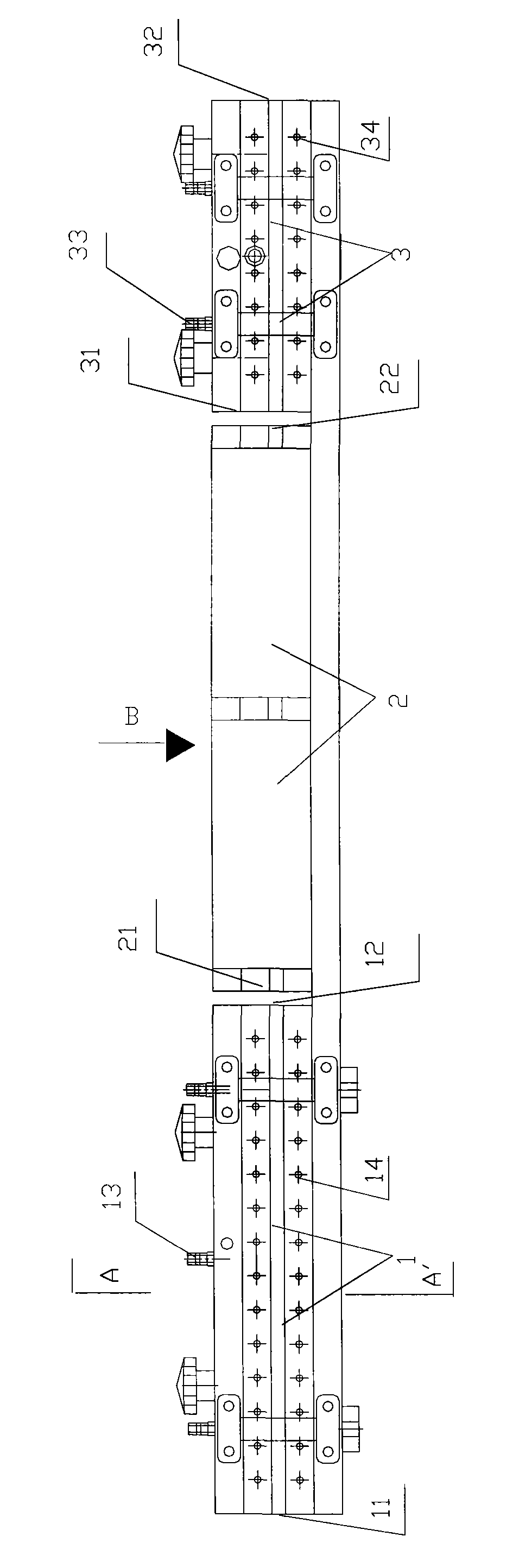

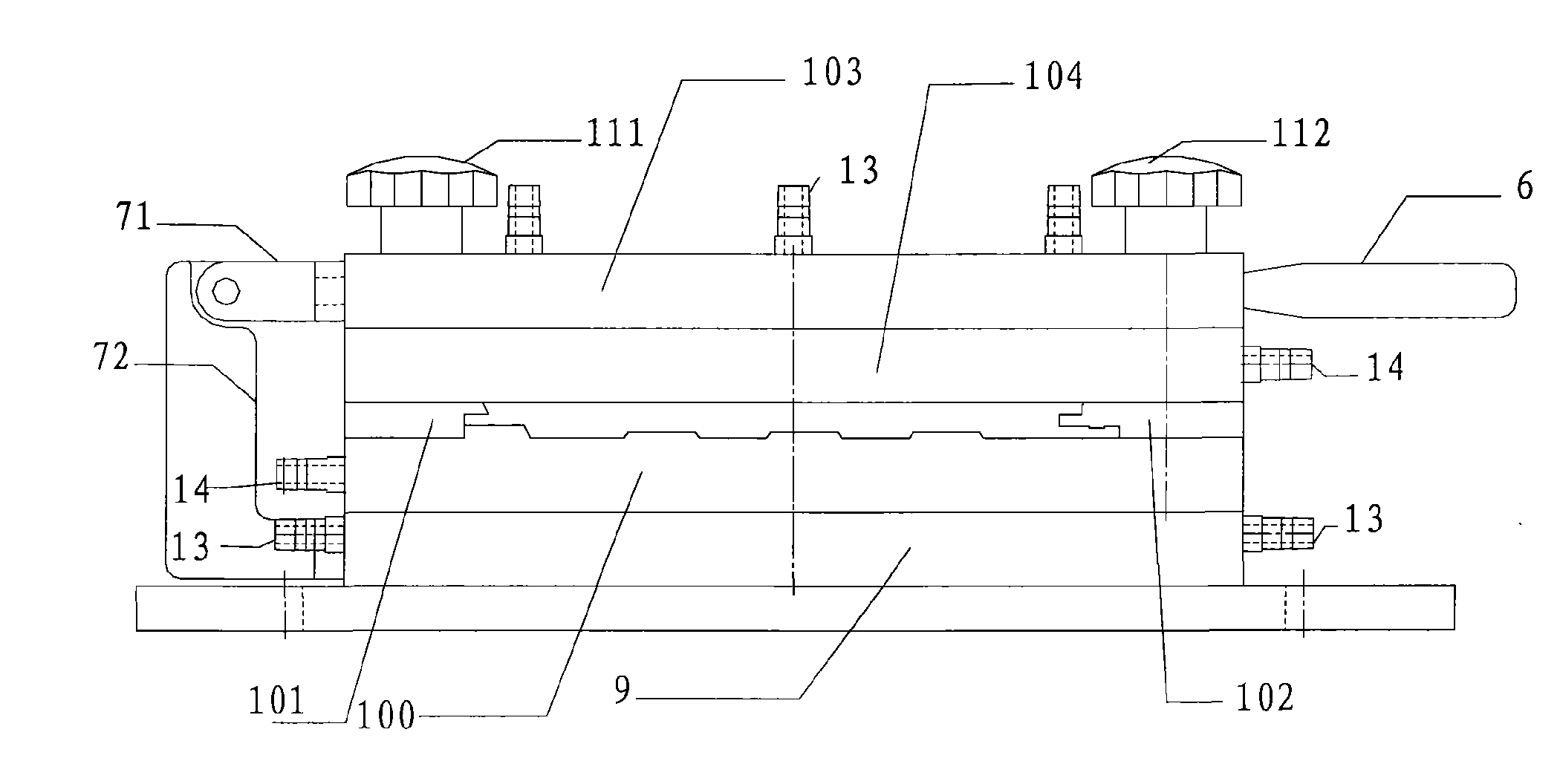

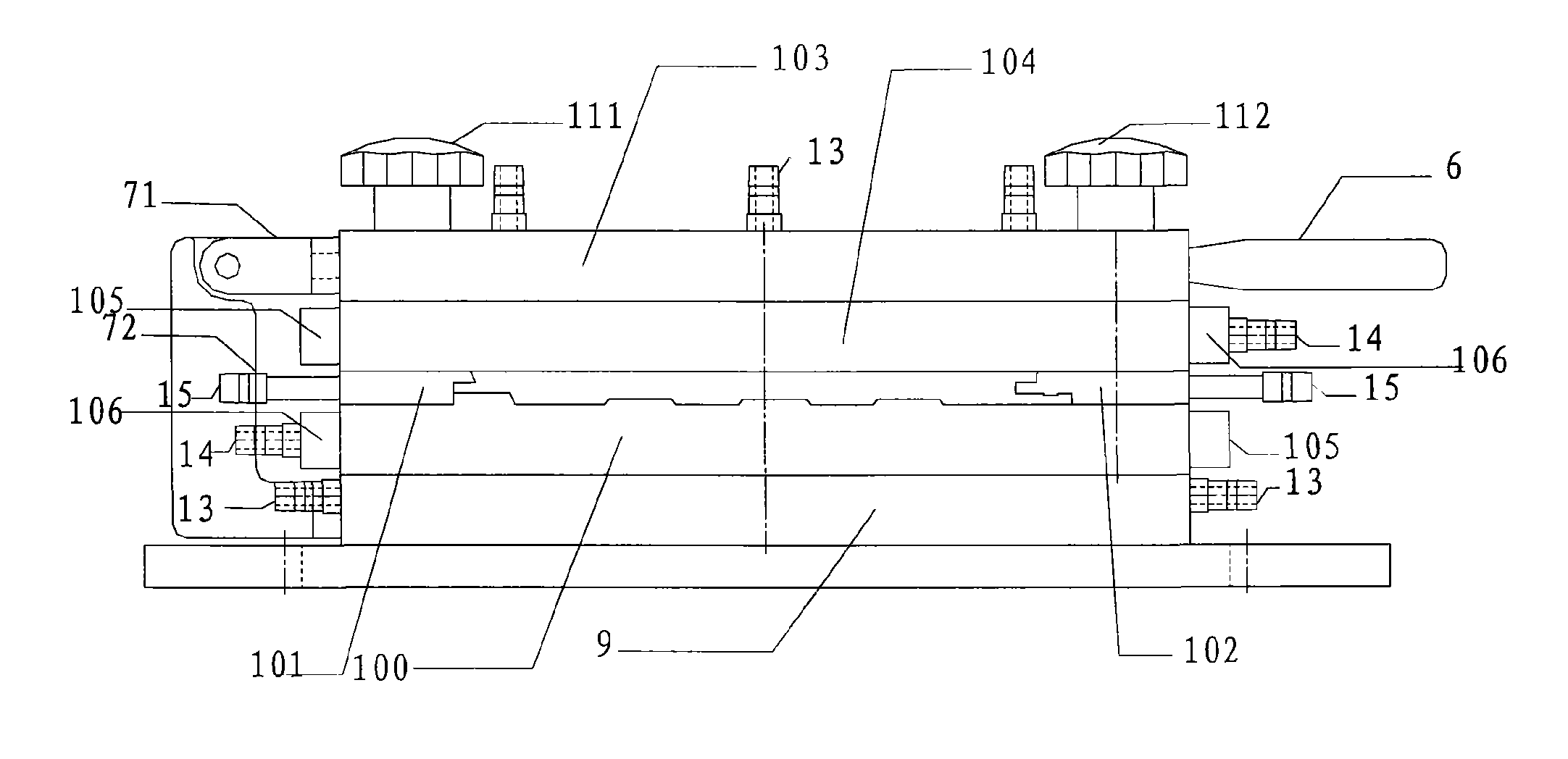

[0038] Such as figure 1 , figure 2 As shown, the device includes three parts, the first part is the first section of dry calibrating mold 1, one end of the first section of dry calibrating mold 1 is a profile inlet 11, the other end is a profile outlet 12, the first section of dry calibrating The inside of the mold 1 includes a shaping cavity, a cooling pipeline and a vacuuming pipeline, and the shape of the shaping cavity is adapted to the shape of the plastic profile to be processed; the second part of the device is an open rectangular parallelepiped The water tank 2 is equipped with cold water inside, and the third part is the second section of dry calibrating die 3. One end of the open water tank 2 is adjacent to the profile outlet 12 of the first section of dry calibrating die 1, and a profile is provided at this end Inlet 21, the other end of the open cooling tank 2 is adjacent to the second section of dry calibrating mold 3, and a profile outlet 22 is provided at this...

Embodiment 2

[0040] Such as figure 1 , image 3 As shown, the device includes three parts, the first part is a first section of dry calibrating die 1 with a length of 44cm to 45cm, one end of the first section of dry calibrating die 1 is a profile inlet 11, and the other end is a profile outlet 12, The inside of the first dry-type calibrating mold 1 includes a calibrating mold cavity, a cooling pipeline and a vacuuming pipeline, and the shape of the calibrating mold cavity is adapted to the shape of the plastic profile to be processed; the second part of the device is a The shape is the open tank 2 of cuboid, and cold water is housed inside, and the third part is the second section dry setting mold 3 whose length is between 27cm and 29cm, and one end of the open tank 2 is connected with the first section dry setting mold 1 The profile outlet 12 is adjacent, and a profile inlet 21 is provided at this end, and the other end of the open cooling tank 2 is adjacent to the second section dry ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com