Lapel-type bag shaper with multiple conical surfaces

A bag forming and multi-cone technology, which is applied in the direction of containers, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of complex structure of bag making machine, limited selection of bag making materials, increase of manufacturing cost of bag making machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

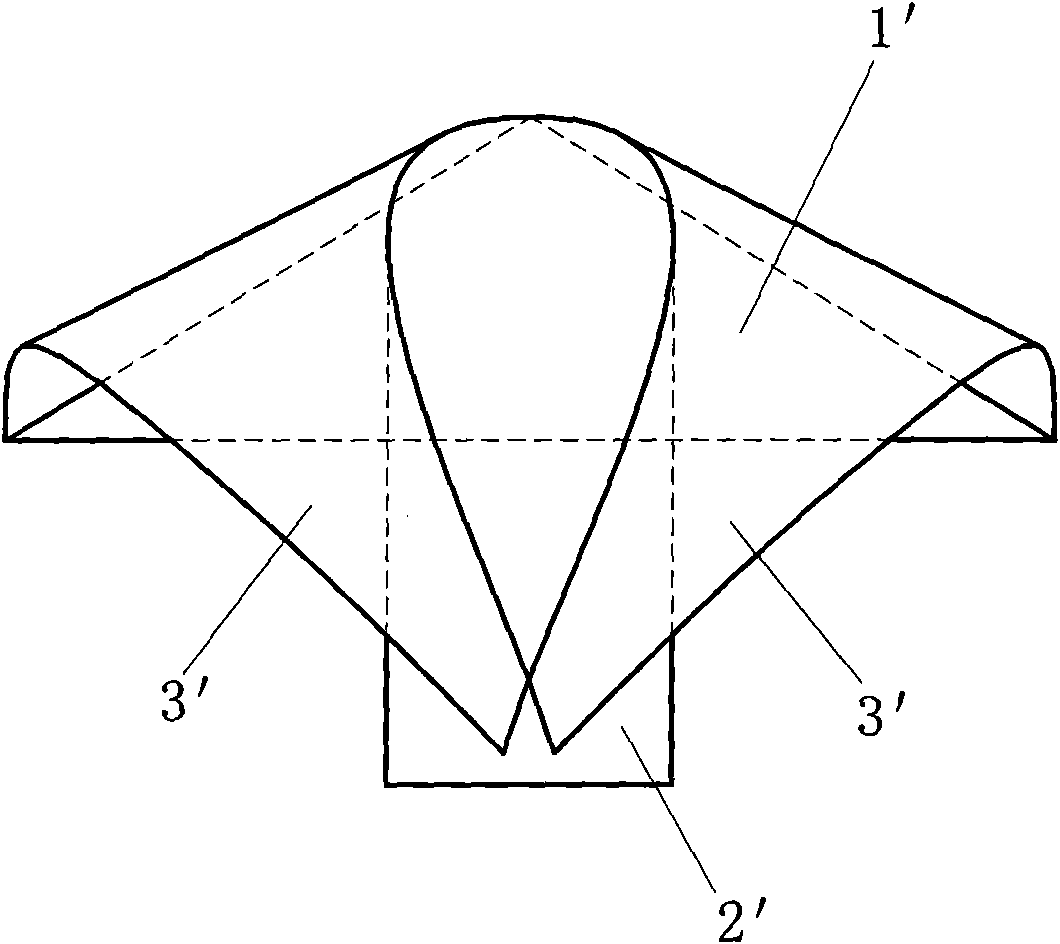

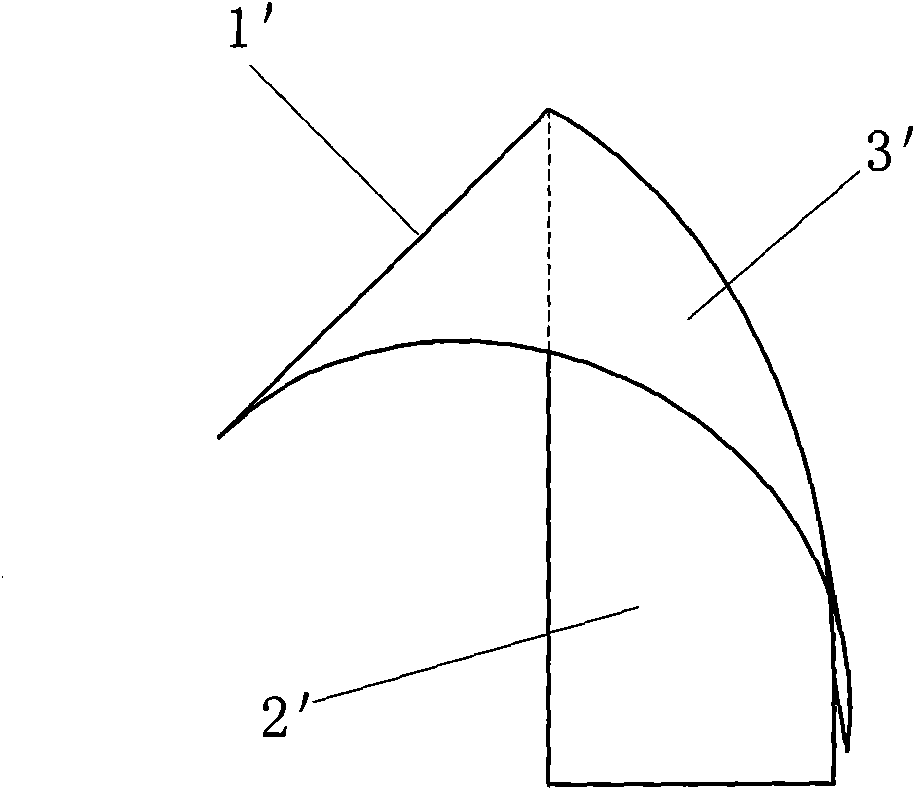

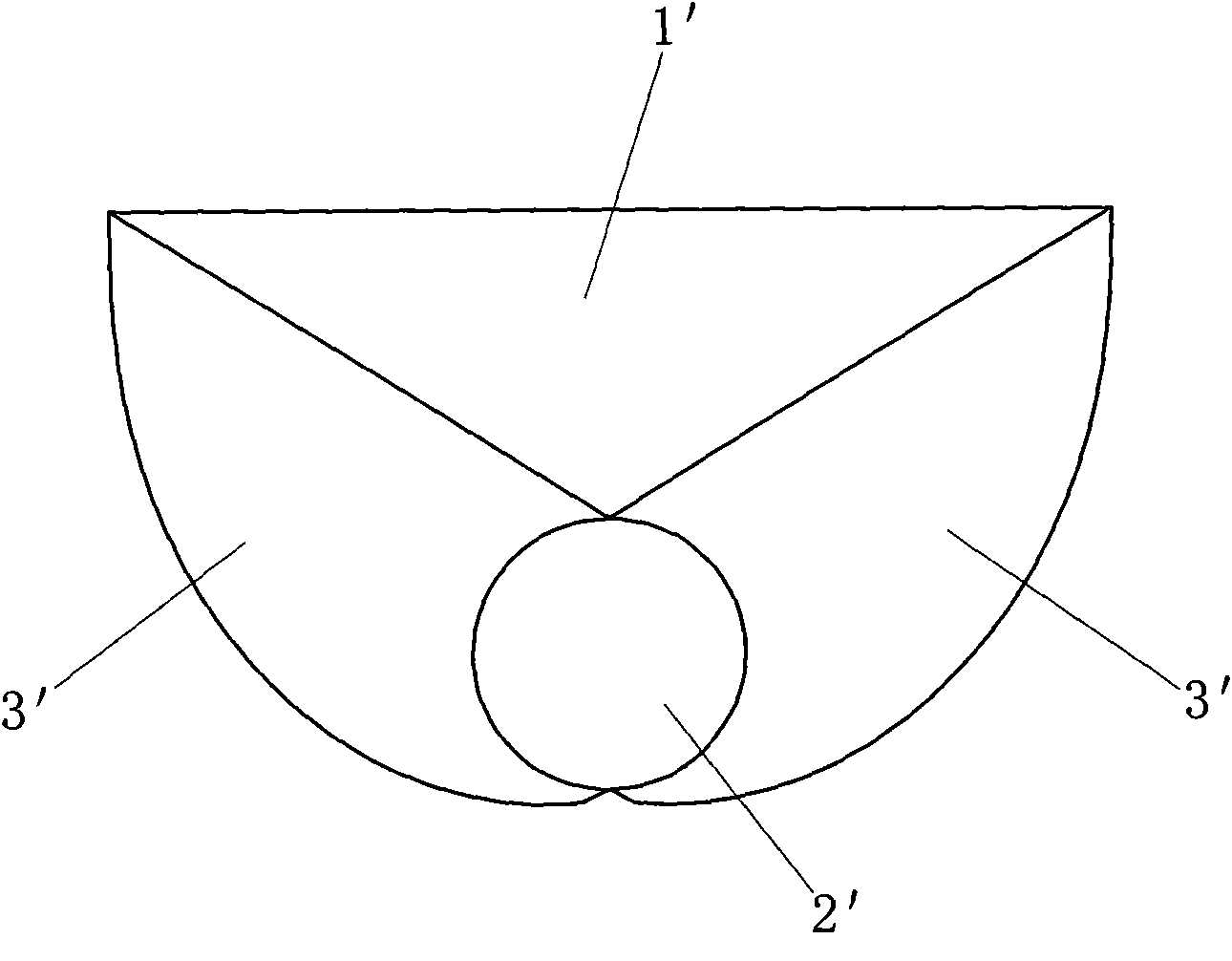

[0032] like image 3 , 4 , 5 and 6, the present invention comprises a back plane 1, a cylindrical standpipe 2 and two shoulder curved surfaces symmetrically arranged on both sides of the back plane (such as image 3 In XOZ plane symmetry), the shoulder surface is formed by connecting the first conical surface 3 and the second conic surface 4, the first conical surface 3 and the second conical surface 4 are tangent at the common generatrix 5, the first conic surface 3, There is a smooth transition between the second conical surface 4 and the back plane 1, and the back plane 1, the first conical surface 3, the second conical surface 4, and the inner wall of the cylindrical standpipe 2 together form a developable curved surface (expansion diagram as shown in FIG. Figure 7 ), two symmetrically arranged second conical surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com