Method for producing waxy corn starch

A technology of waxy corn starch and waxy corn, applied in food preparation, food science, application and other directions, can solve the problems of less equipment, small production volume, unable to meet market demand, etc., and achieve the effect of good soaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

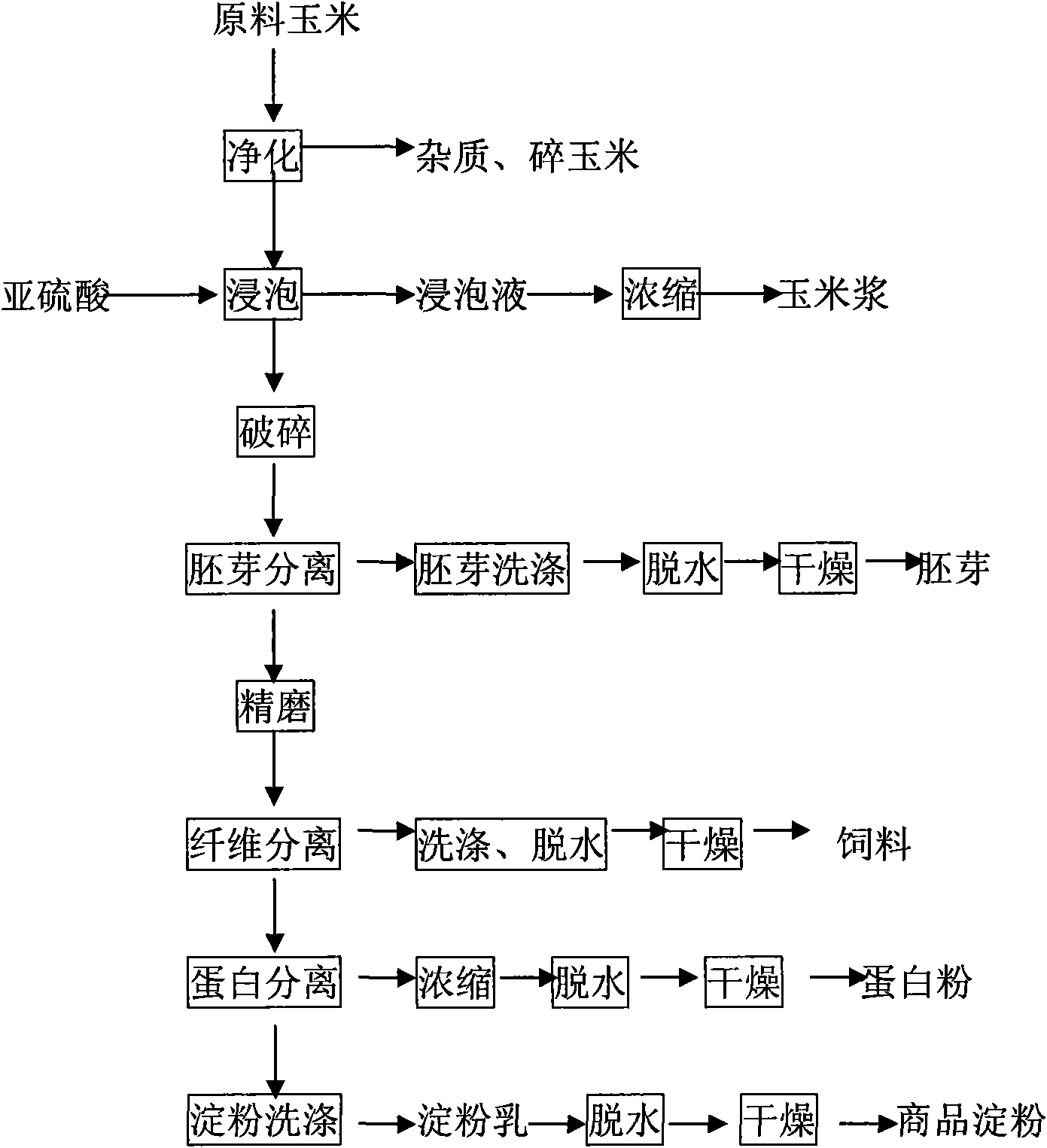

Method used

Image

Examples

Embodiment Construction

[0024] The present invention pays attention to the following points during implementation:

[0025] 1. Raw material requirements for waxy corn:

[0026] Different varieties of waxy corn have different grain size, color, waxy strength, and grain thickness, and the selection of varieties has a greater impact on the quality and quantity of processed products. Therefore, in the implementation process, varieties with larger grains, stronger waxiness and thinner skins should be selected. The passing rate of the waxy test is 99%, and the miscellaneous particles do not exceed 1%.

[0027] 2. Quality requirements for waxy corn starch:

[0028] As a food raw material, waxy cornstarch has almost no amylose, more than 95% amylopectin, and a peak viscosity of more than 600BU except that it meets the national standard for edible cornstarch (GB8885-88). It has strong viscosity and good film-forming properties, and its paste liquid has good stability, high transparency and is not easy to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com