Glass soaking device

A glass and soaking box technology, applied in the coating and other directions, can solve the problems of insufficient use of fireproof liquid and high consumption of fireproof liquid, and achieve the effect of enhancing soaking effect, improving efficiency and enhancing contact degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

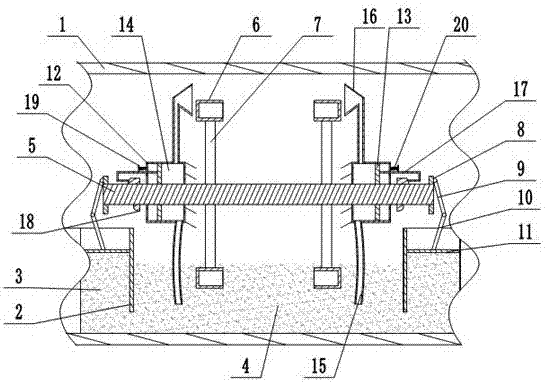

[0024] The reference signs in the drawings of the description include: soaking box 1, partition plate 2, compartment 3, soaking chamber 4, rotating shaft 5, clamping seat 6, pole 7, turntable 8, crank 9, connecting rod 10, slider 11. Support cylinder 12, piston plate 13, compression chamber 14, liquid inlet pipe 15, spray pipe 16, ejector rod 17, cam 18, baffle plate 19 and spring 20.

[0025] The embodiment is basically as attached figure 1 Shown:

[0026] The glass soaking device is mainly composed of a soaking box 1, a compartment 3, a soaking chamber 4, a rotating shaft 5, a clamping seat 6, an extruding mechanism, a spraying mechanism, and a linkage mechanism. The soaking box 1 is used to hold the fireproof liquid; the left and right ends of the lower part of the soaking box 1 are equipped with partitions 2, the partitions 2 and the inner wall of the soaking box 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com