Method for real-time online calculation and measurement of separation efficiency of separator

A separation efficiency and measurement method technology, applied in the field of electric power, can solve the problems of low accuracy and reliability of test results, high test difficulty, and low accuracy of measurement results, and achieve real-time calculation or measurement, accuracy and reliability assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

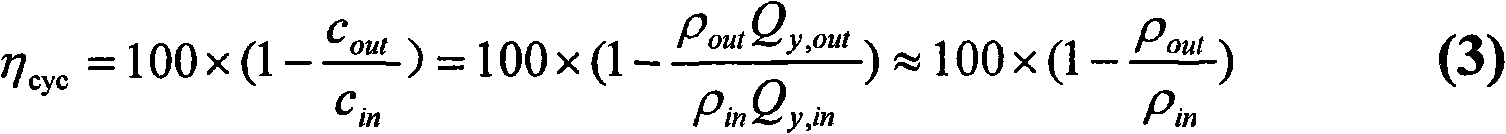

[0044] The present invention first studies the measuring points of circulating fluidized bed boilers (or with separator equipment), and determines the measuring points, related parameters and correction coefficients needed for real-time calculation; The calculation method can be used to calculate the separator efficiency of the separator in real time; the separator efficiency of the separator can also be determined by the following method through manual recording and off-line measurement data.

[0045] 1) Obtain the average material concentration in the upper part of the furnace through the differential pressure value;

[0046] ρ up = P mid - P up gh mid - up

[0047] In the formula: ρ up ——the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com