Single-arm combined boring tool

A combined, boring tool technology, applied to boring bars, accessories of tool holders, tools for lathes, etc., can solve the problems of cumbersome structure, troublesome combination, inconvenient adjustment, etc. The effect of a wide range of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

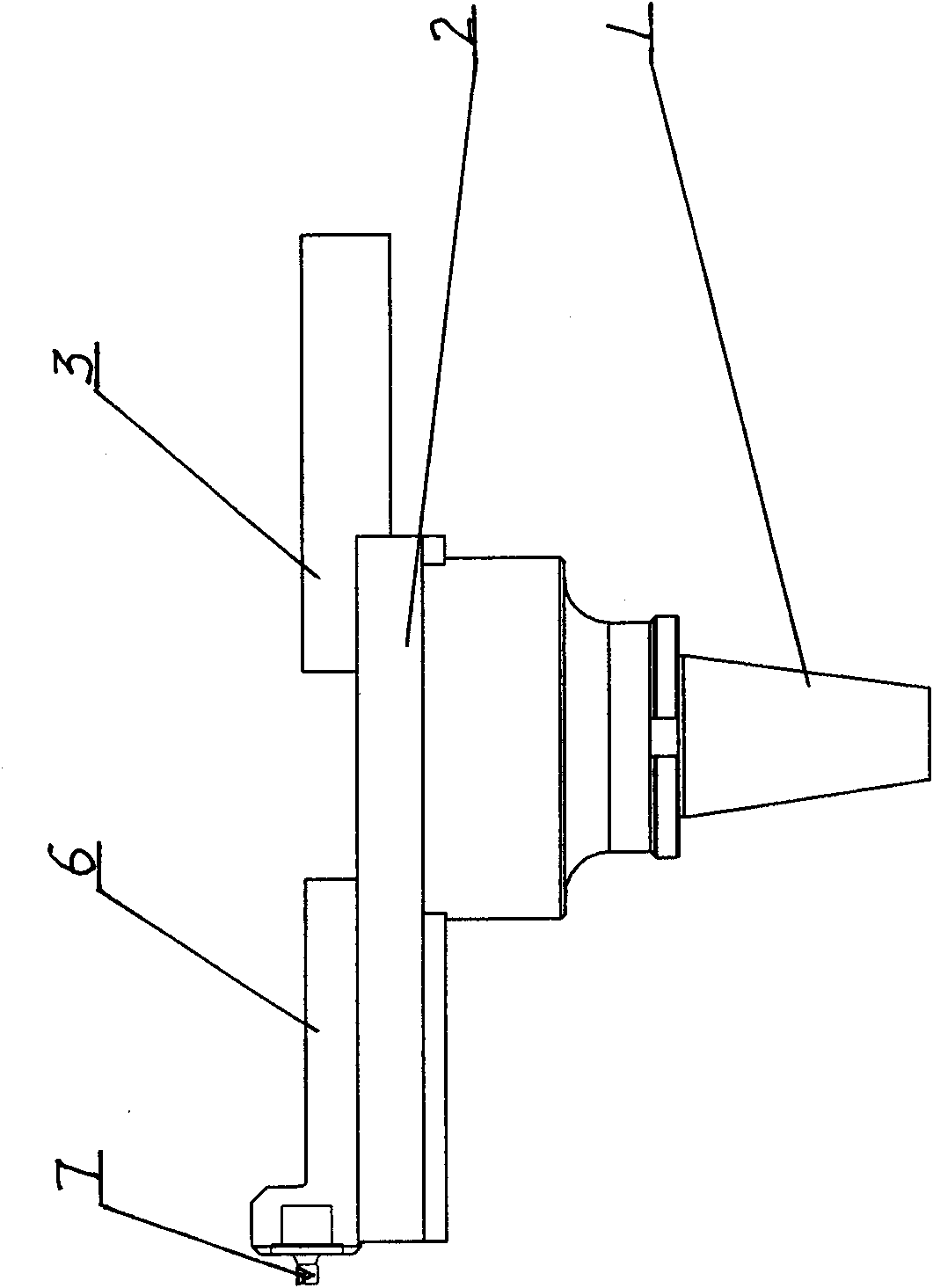

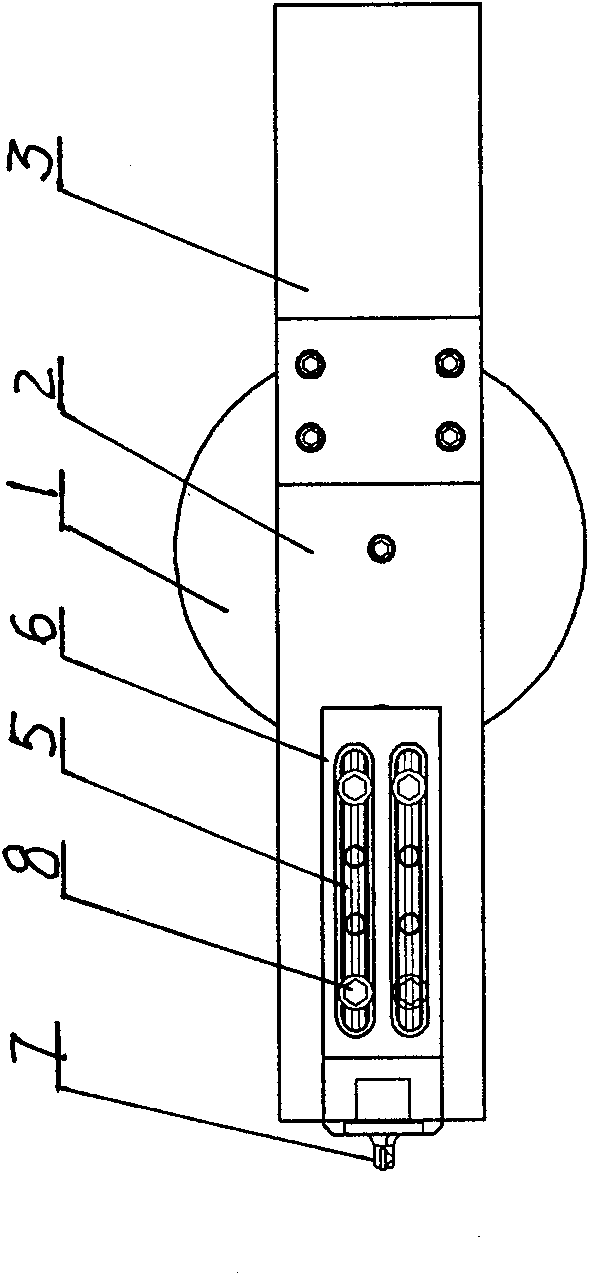

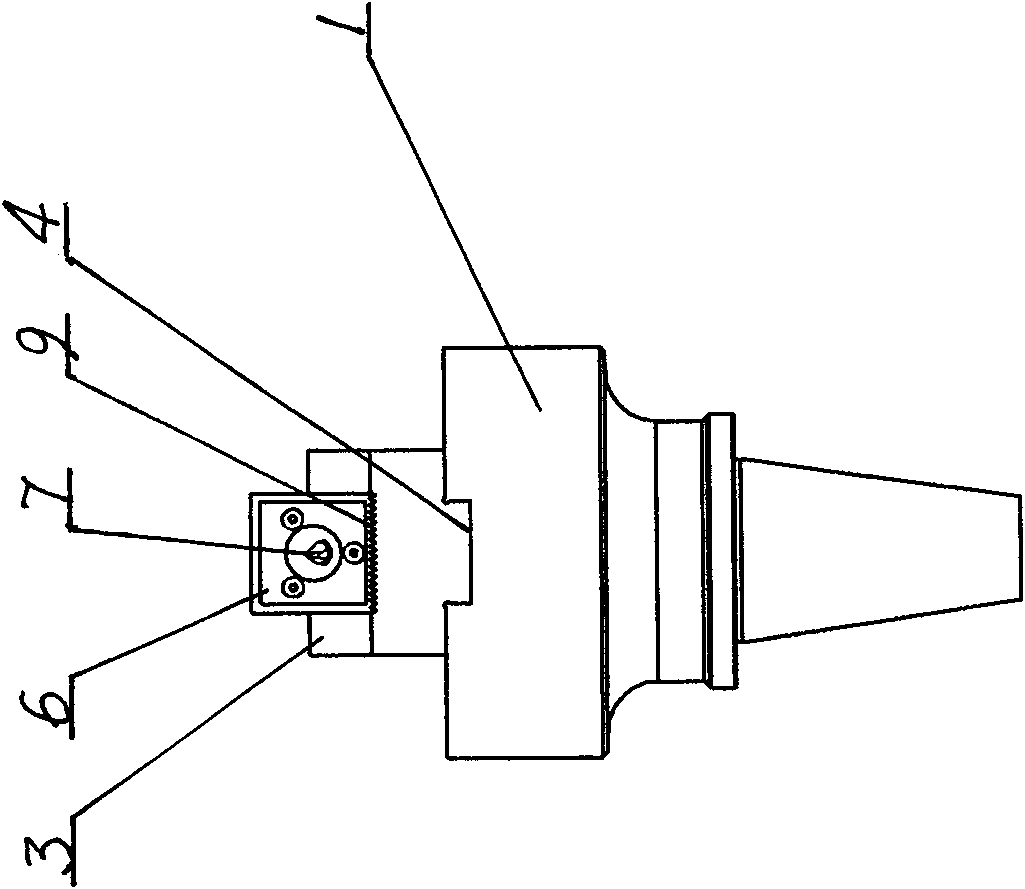

[0028] The present invention comprises a knife handle 1, a support rod 2 is arranged in a guide groove 4 at the end of the knife handle 1, one end of the support rod 2 is a balance weight 3, the other end of the support rod 2 is provided with a sliding knife rod 6, and the outer surface of the sliding knife rod 6 End is provided with boring tool 7.

[0029] The bottom of the sliding tool bar 6 is combined with the top of the support bar 2 in a zigzag shape 9; the sliding tool bar 6 and the supporting bar 2 are kept firm and stable during the working process of the boring tool 7.

[0030] Sliding knife bar 6 is provided with longitudinal groove 5, and support bar 2 is provided with corresponding fixing screw 8 of longitudinal groove 5; In order to adjust the position of fixing screw 8 of longitudinal groove 5 relative support bar 2, determine the boring on sliding knife bar 6. The machining position where the knife 7 is located.

[0031] One end of the sliding tool bar 6 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com