Door sealing batten of container

A container and beading technology, which is applied in packaging, windows/doors, door/window applications, etc., can solve problems such as poor bonding and sealing performance, unreasonable appearance and structure of door seal beading 10, and reduced sealing performance, etc., to achieve easy injection molding, Simple structure and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

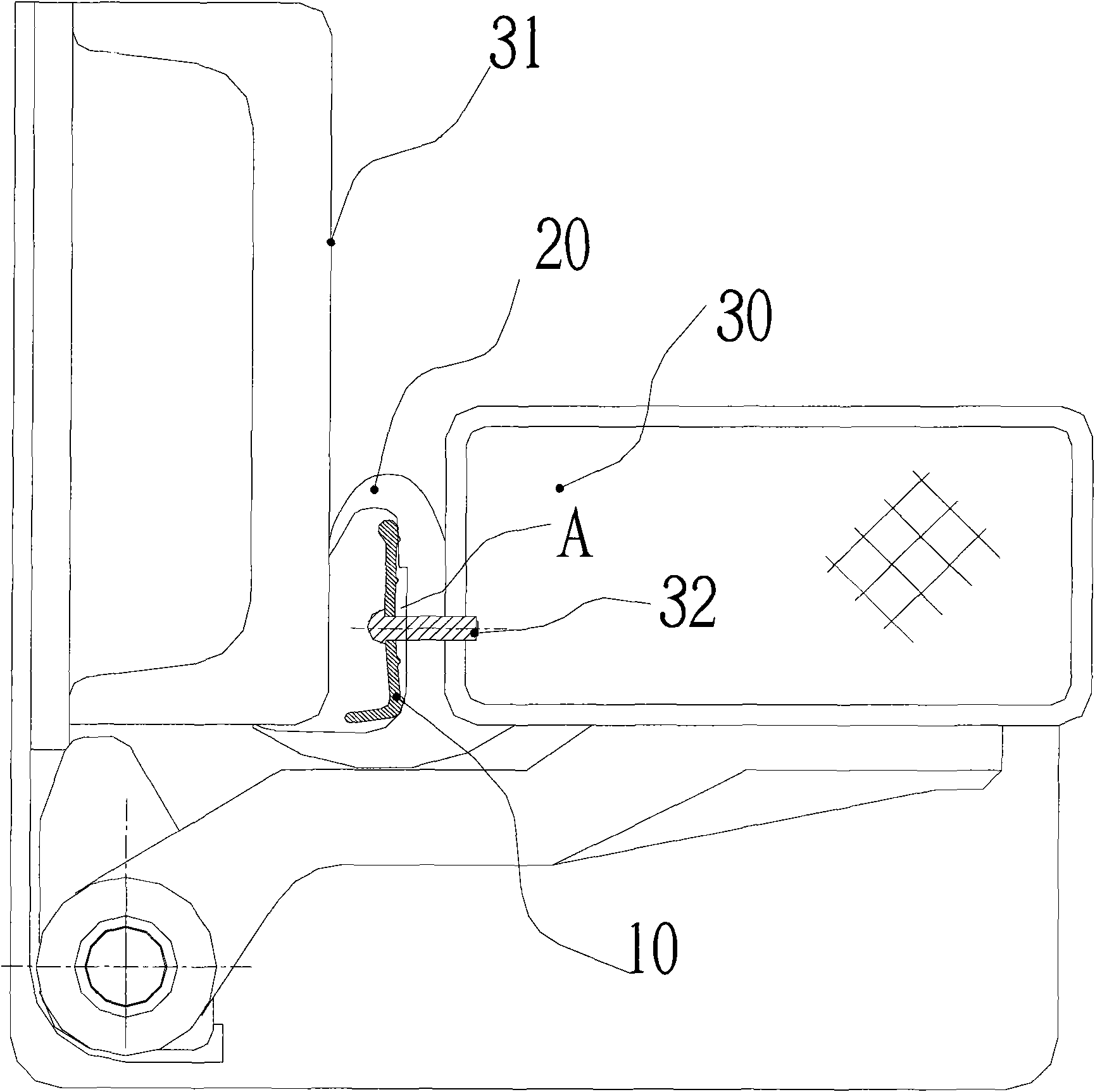

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

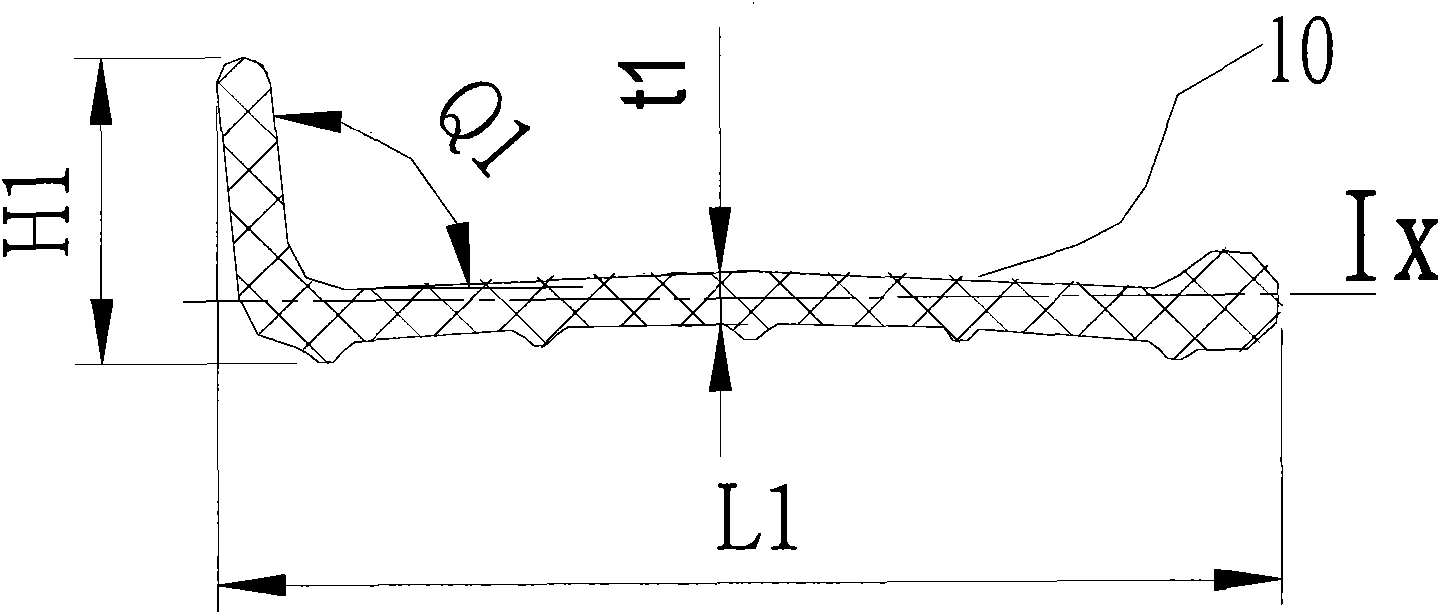

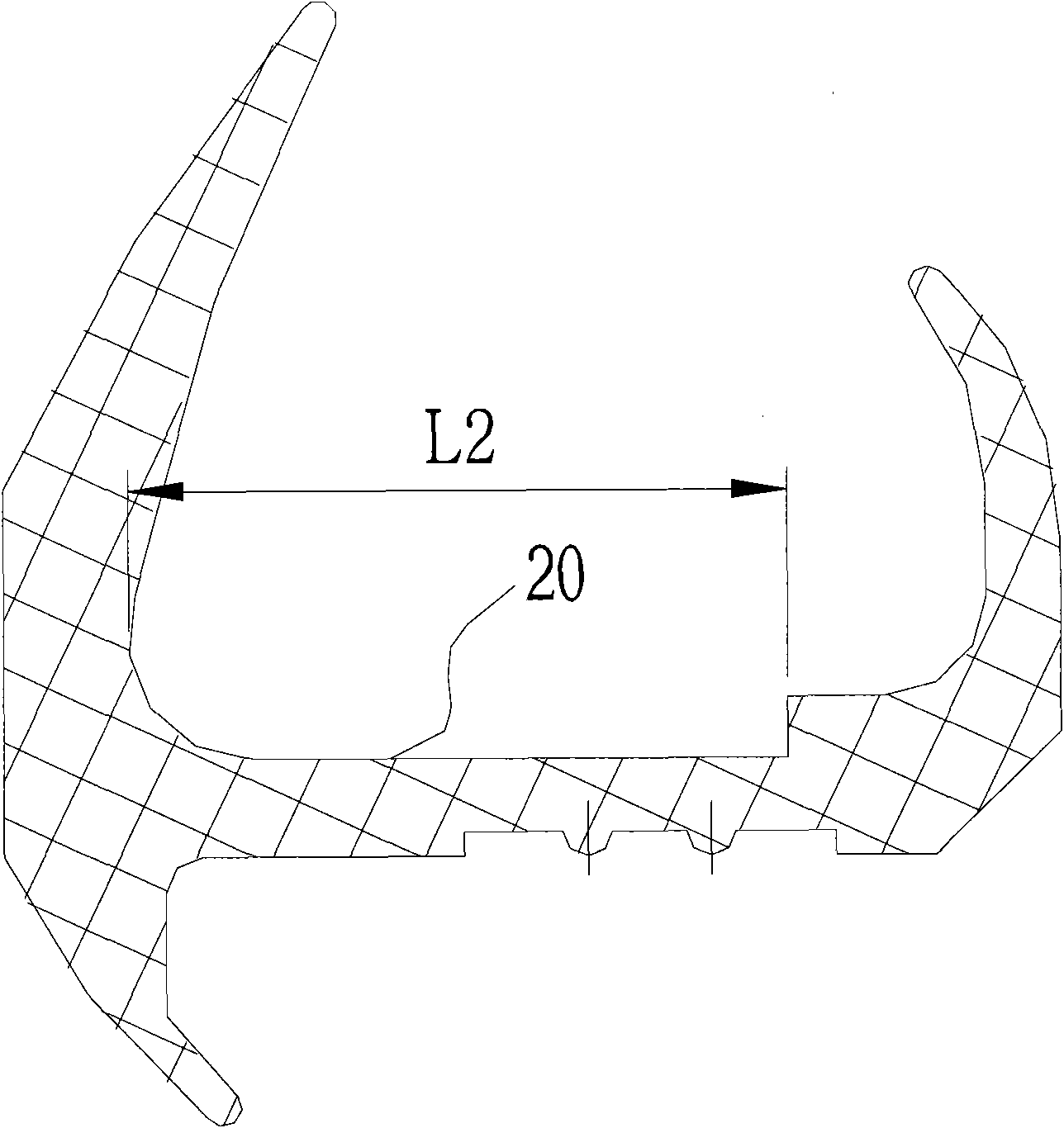

[0026] like Figure 4 , 5 As shown, the door sealing strip is a straight strip 40 with an L-shaped cross section. The straight strip 40 includes a pressing plate 41 for pressing the door sealing strip and a reinforcing plate 42 located on one side of the pressing plate 41. The straight strip 40 is mostly It is made of impact-resistant acrylonitrile-butadiene-styrene copolymer (abbreviated as ABS) material, and can also be made of other polymer materials or composite materials. H is 4mm~19mm, the thickness t of pressing plate 41 and reinforcing plate 42 is 1mm~4mm, the angle Q between the two is 90 degree~110 degree, the moment of inertia Ix of straight bar 40 is no less than 210.164mm4.

[0027] For example: the length L of a door seal bead 402 is 22 mm, the height H is 10 mm, the thickness t of the pressure plate 41 and the reinforcement plate 42 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap