Expansion scraper blade plate-type conveyer

A conveyor and scraper technology, applied in the field of telescopic scraper conveyor, can solve the problems of large turning radius, conveying failure, inconvenient movement, etc., and achieve the effect of increasing the extension length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

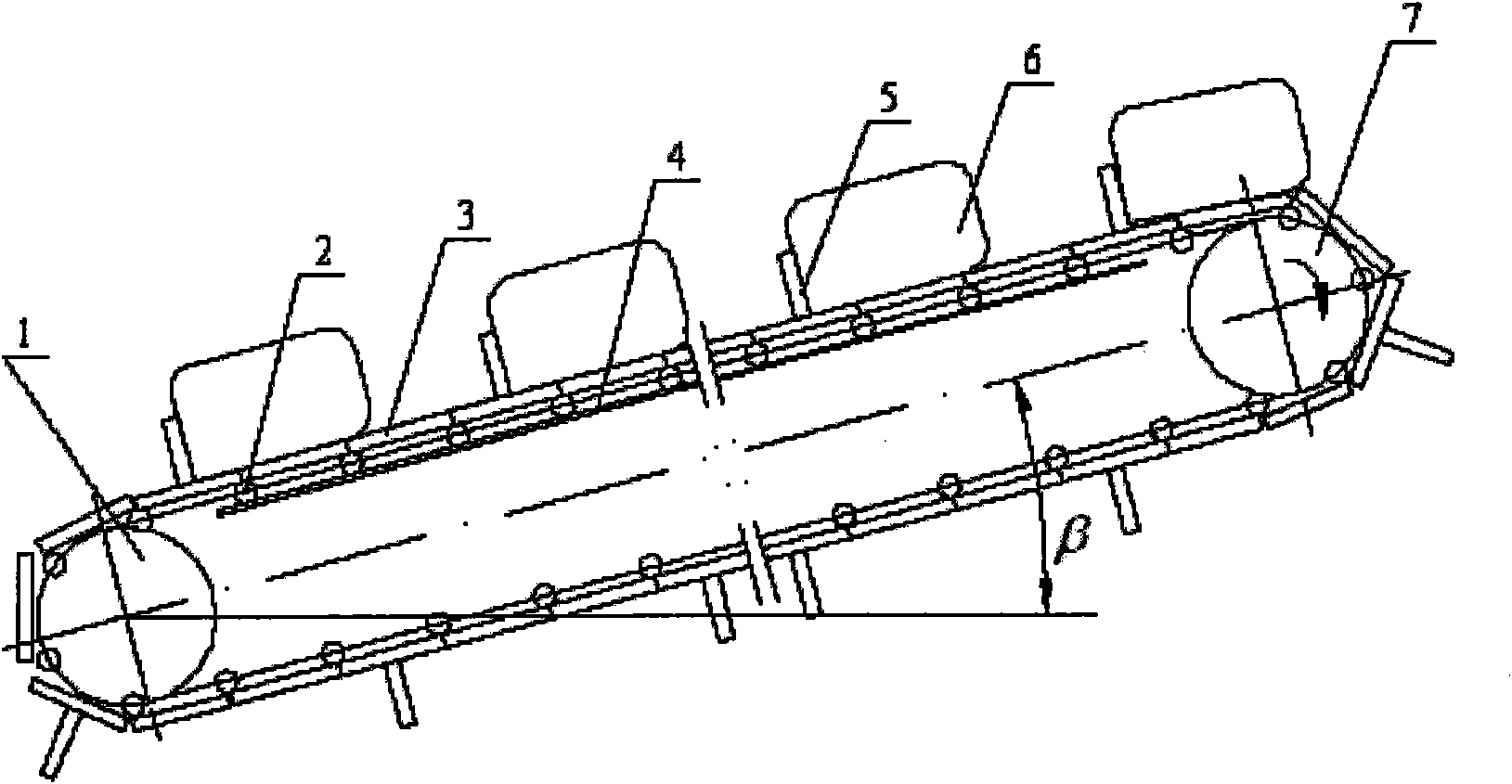

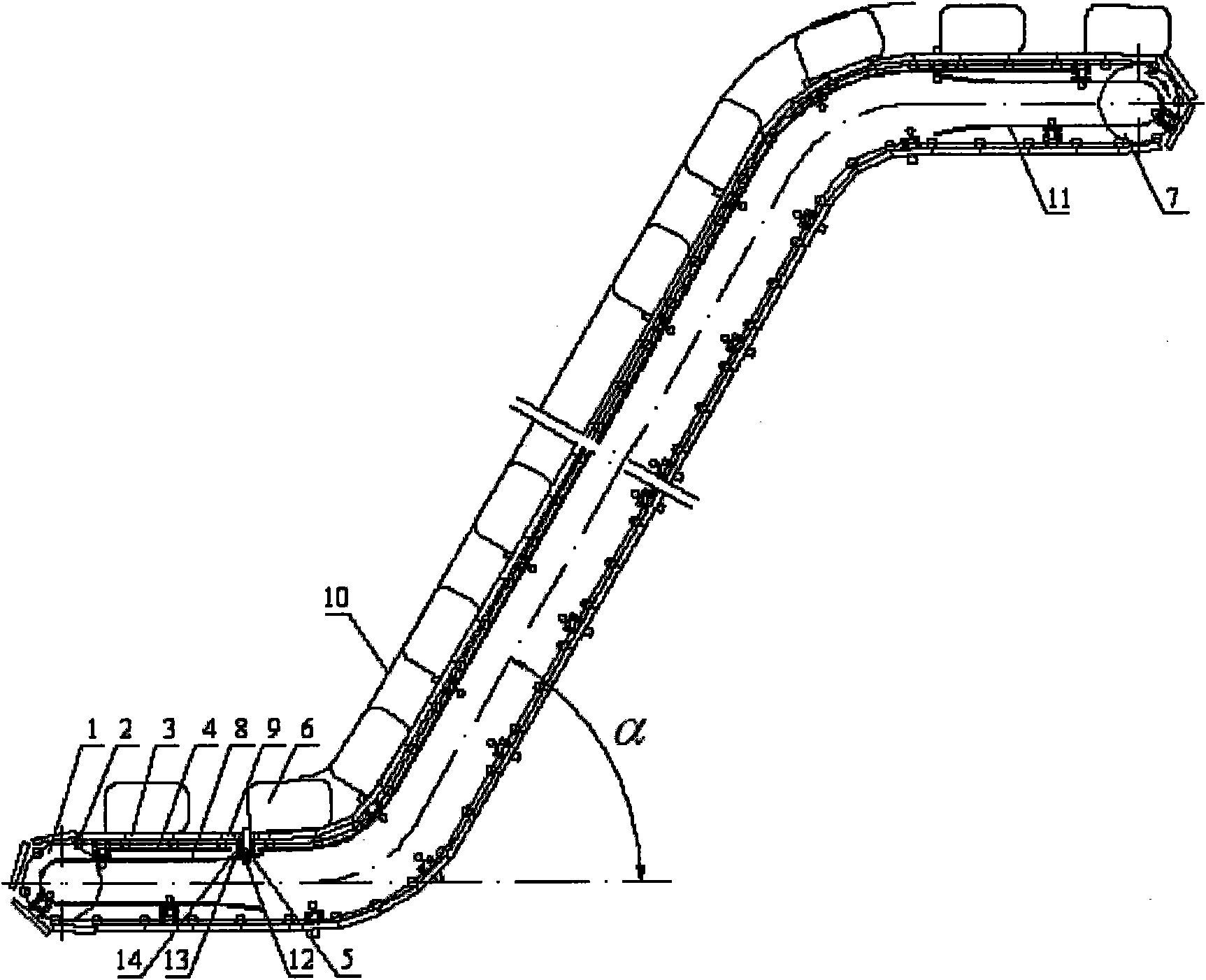

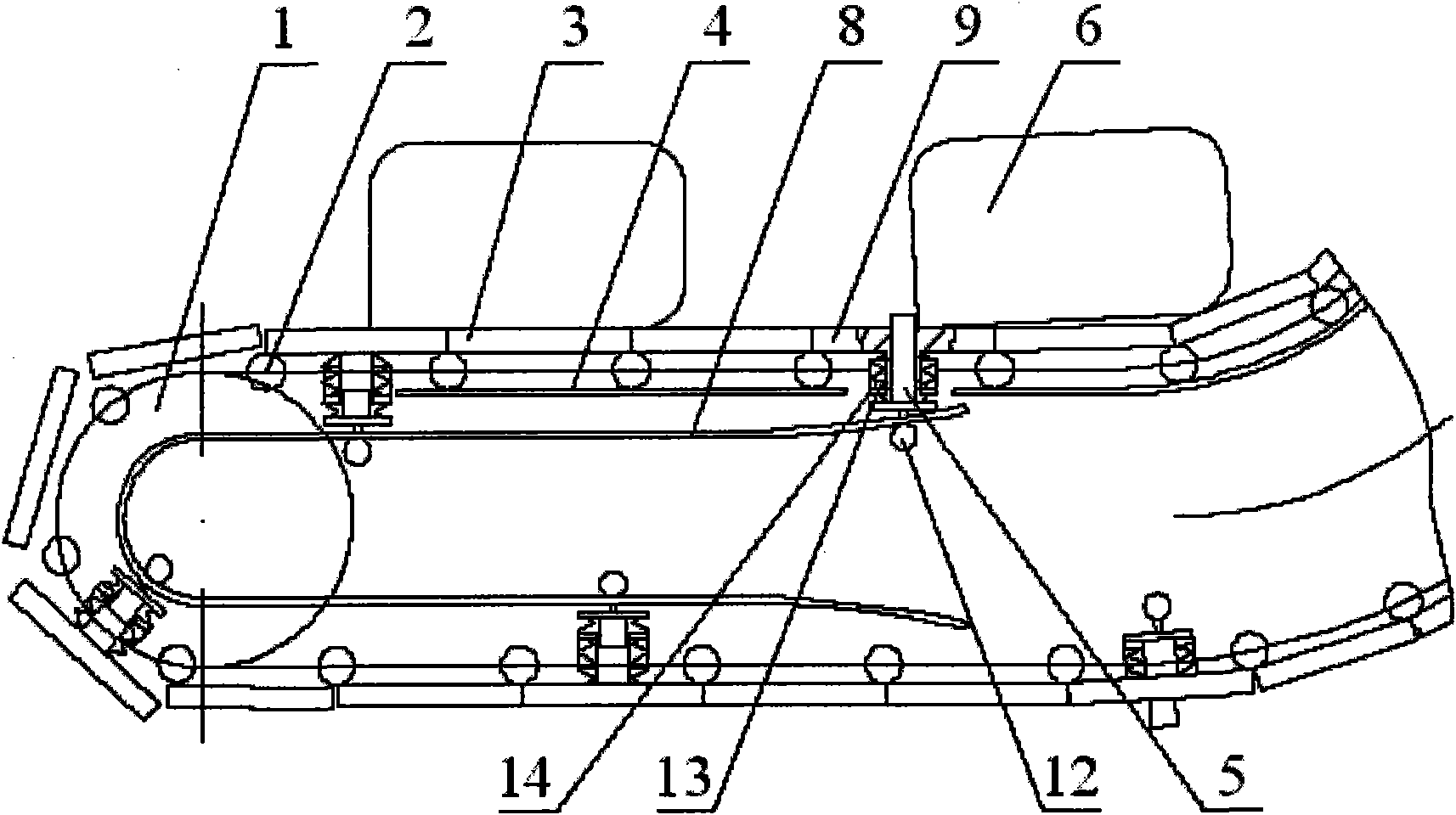

[0025] Such as Figure 2-7 As shown, the conveyor is composed of a tail wheel 1, a conveyor chain 2, a slat 3, a guide rail 4, a scraper 5 and a head wheel 7 installed on the frame, and the head wheel 7 and the tail wheel 1 are respectively installed at both ends of the frame. , the conveyor chain 2 bypasses the head wheel 7 and the tail wheel 1 and meshes with the head wheel 7 and the tail wheel 1, the conveyor chain 2 is supported on the guide rail 4 located on the frame, and the strip 3 is fixed on the conveyor chain 2; it is characterized in that: A telescopic scraper is installed on the conveyor chain 2, and the telescopic scraper includes a scraper 5, a guide plate 9, a connecting plate 13 and a spring 14, and a group of guide plates 9 are installed at intervals on the conveyor chain 2, and the scraper 5 is positioned at the edge of the guide plate 9. In the middle, connecting plates 13 are installed symmetrically on both sides of the scraper 5, one end of at least two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com