Self-driven air charging valve

An inflatable valve, self-operated technology, used in the field of rubber-lined butterfly valves, can solve the problems of difficult control of sealing interference and large opening and closing torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

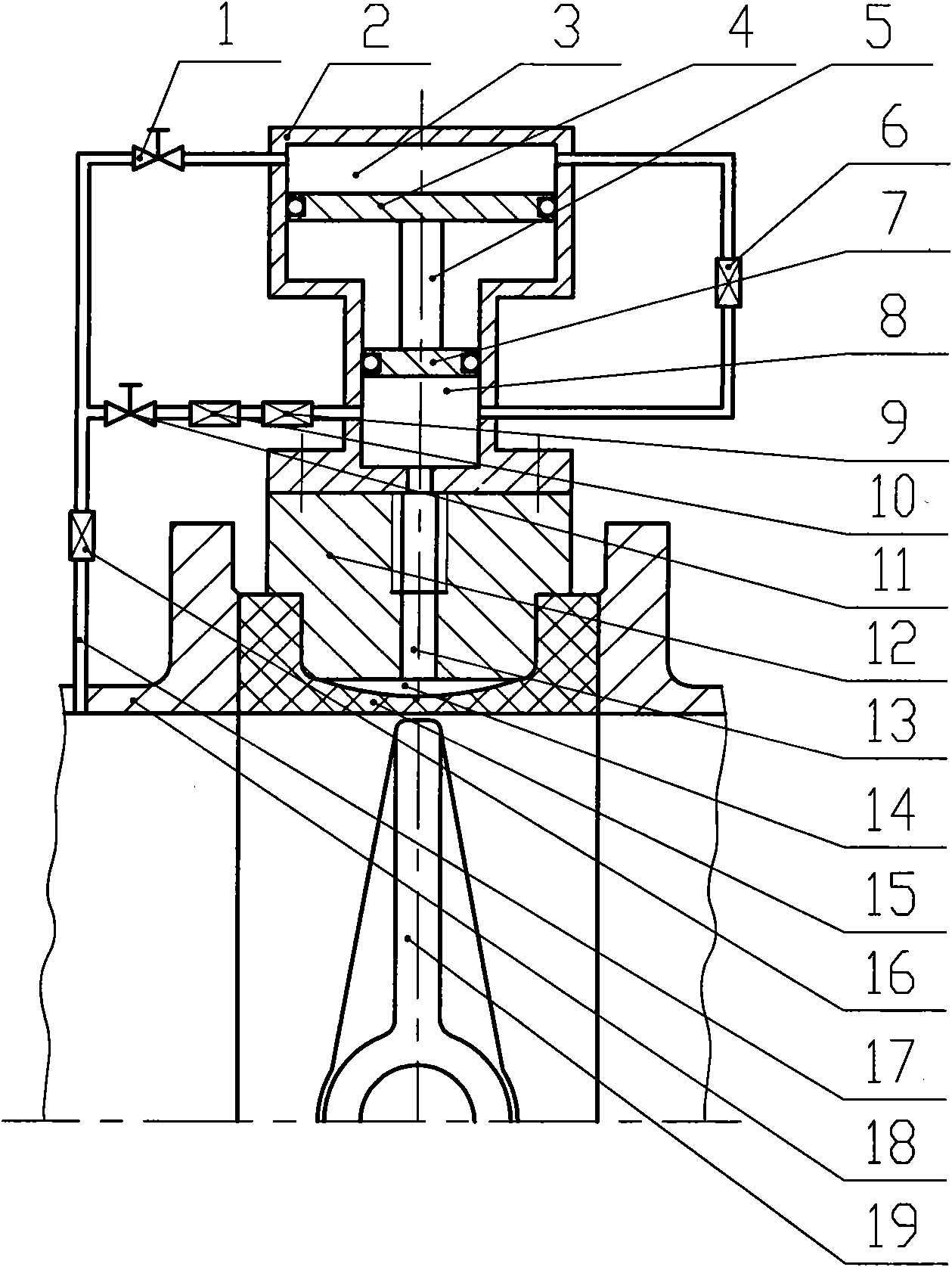

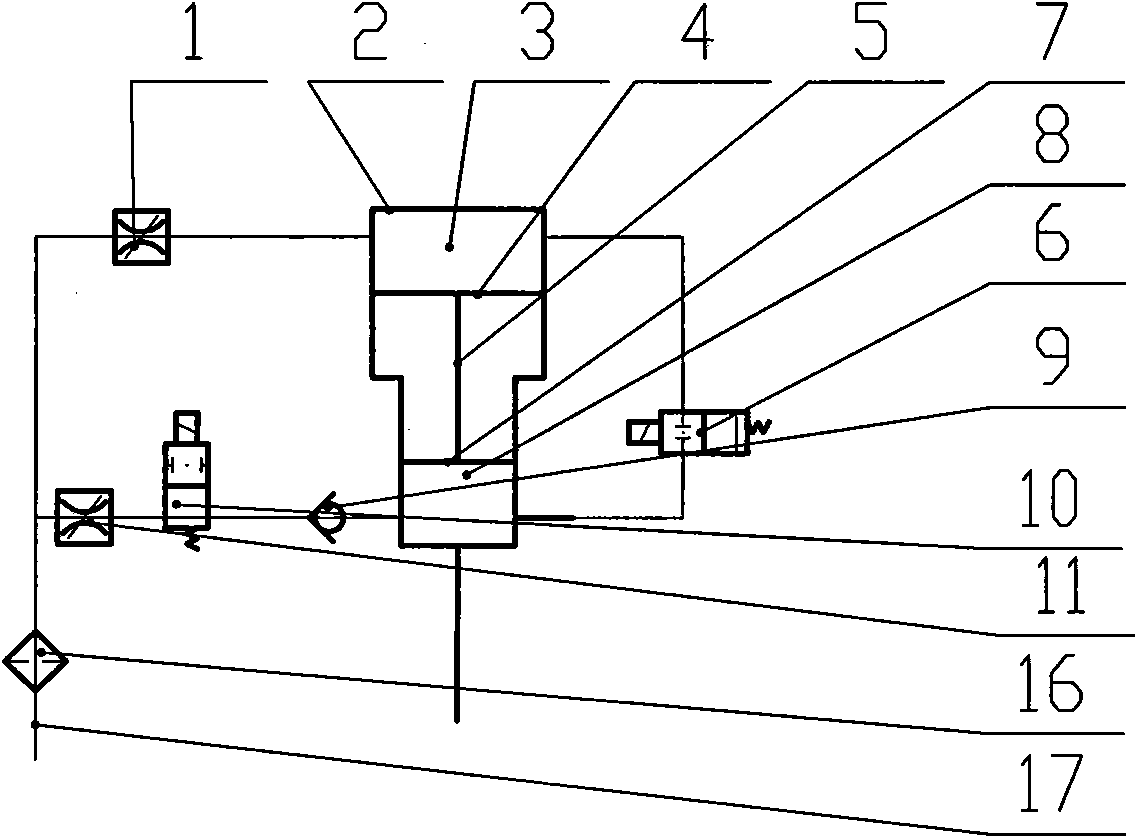

[0011] Such as figure 1 , 2 As shown, a self-operated inflation valve includes a valve body 12, a rubber valve seat 15, and a butterfly plate 19. The rubber valve seat 15 is installed in the valve body 12, and the valve body 12 has an air inlet 13, which is connected to the valve body 12. It communicates with the air bag cavity 14 formed between the rubber valve seat 15; a cylinder 2 is also installed above the air intake hole 13, and the cylinder 2 is divided into two chambers up and down, the diameter of the upper chamber 3 is greater than the diameter of the lower chamber 8, and there is an upper chamber in the upper chamber 3. Piston 4, lower piston 7 is arranged in the lower chamber 8, and upper piston 4 is connected with lower piston 8 by connecting rod 5; On the pipeline 18, a trachea 17 is also installed, and the trachea 17 is divided into upper and lower roads, and the upper road is equipped with a regulating valve-1 and The upper chamber 3 of the cylinder 2 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com