Plug-in horizontal state sensor

A horizontal state and sensor technology, applied in the field of sensors, can solve the problems of no signal output function and inconvenience, and achieve the effect of high integration, convenient operation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

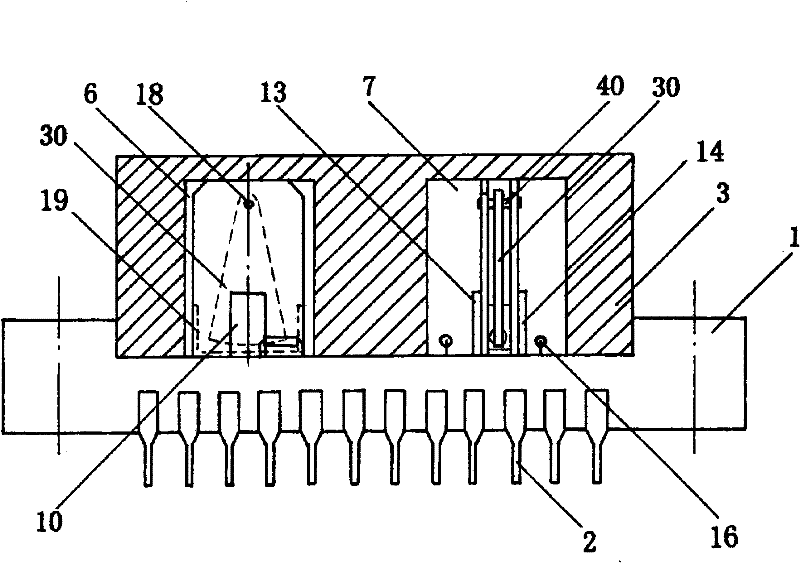

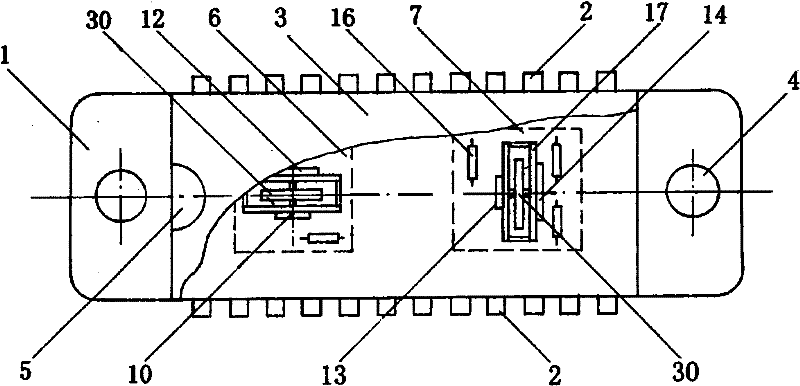

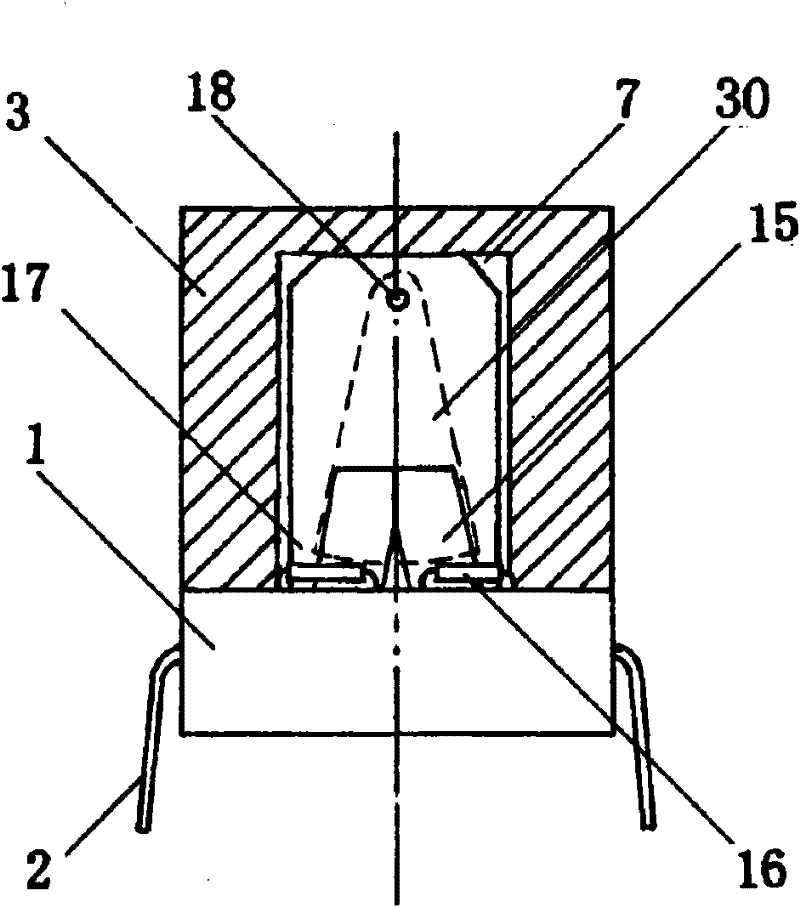

[0040] see Figure 1-12 .

[0041] A plug-in horizontal state sensor, including a base 1, pins 2, a plastic cover 3, a pin number identification mark 5, a fixing bolt hole 4 around the base, and two vertical shafts whose center lines are perpendicular to each other are installed on the base 1. Sensing device (I) 6, vertical sensing device (II) 7; Described vertical sensing device (I) 6, vertical sensing device (II) 7 structures are: two on the base 1 Parallel grooved plate 17, grooved plate 17 upper ends have fixed pin shaft hole 18, pin shaft 40 is installed in the fixed pin shaft hole 18, the middle section of pin shaft 40 pin shaft is upward triangular blade 41, modulation pendulum 30 upper end has sleeve on Swing hinge hole 31 outside bearing pin 40, the top of swing hinge hole 31 has positioning groove 32, and the blade part of triangular blade 41 on pin shaft 40 cuts in the positioning groove 32 of swing hinge hole 31 tops. The front and rear ends of the slot plate 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com