Plate feeding self-adaptive control method

A self-adaptive control, plate technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of inability to be widely used, high technology and equipment costs, different heights of stacked products, etc., to achieve convenient control. , Enhance management and control, reduce the effect of manual input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In this embodiment, the sheet material is loaded by using a sucker to take and transfer the sheet material through negative pressure adsorption.

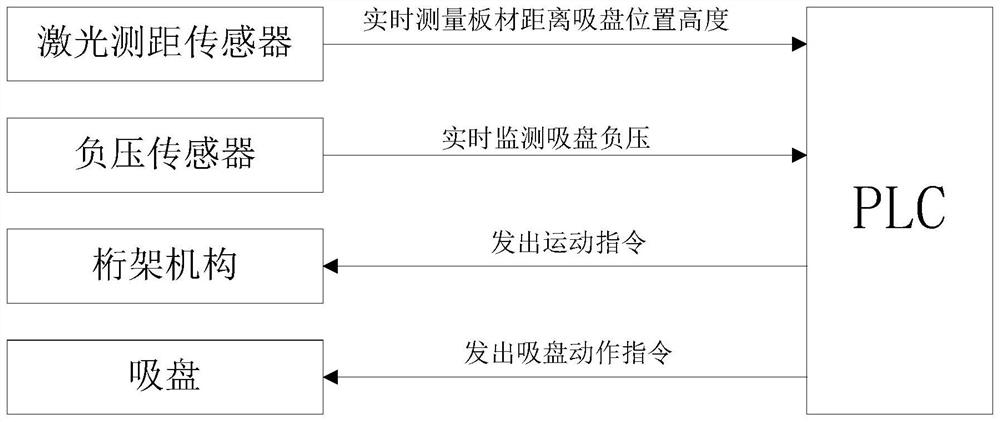

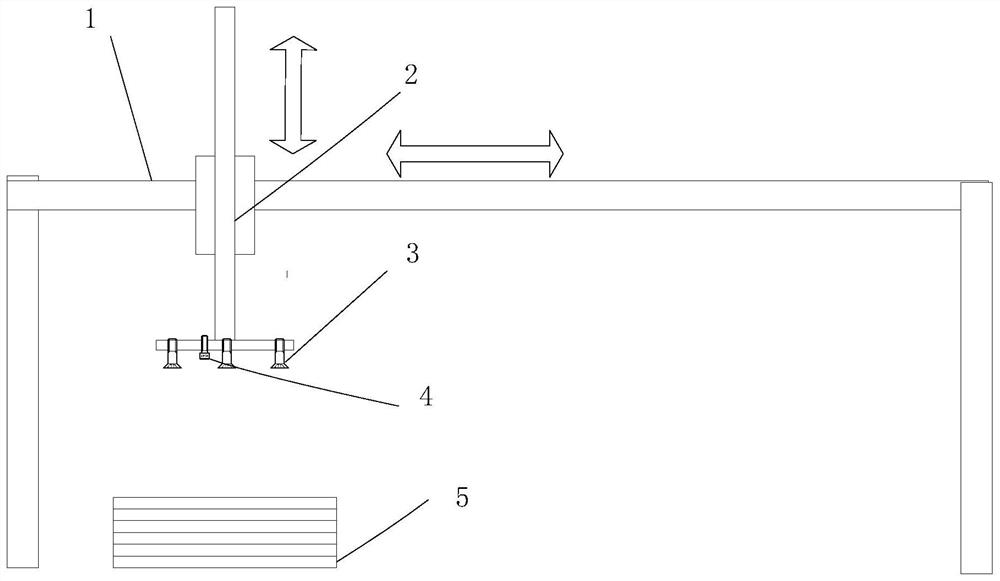

[0039] see figure 1 with figure 2 , in order to realize adaptive control, the adaptive control system is set to include: laser ranging sensor 4, negative pressure sensor, PLC controller, and a motion actuator 2 that drives the suction cup up and down and horizontal transfer, and the motion actuator 2 is set on the truss mechanism 1 on, driven by a servo motor.

[0040] The laser ranging sensor 4 is used for real-time detection of the height value of the sucker 3 from the upper surface of the sheet of the stacked sheet 5 to obtain a height detection signal;

[0041] The negative pressure sensor is set for the negative pressure chamber of the suction cup 3, and is used to monitor the negative pressure of the suction cup in real time and obtain a negative pressure detection signal;

[0042] The PLC controller controls the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com