Front-opening unified pod with wafer constraints arranged on door

A front-opening, wafer box technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of complex structure of wafer restraints, contamination of wafers, poor airtightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to have a more complete and clear disclosure of the technical content used in the present invention, the purpose of the invention and the effects achieved, the detailed description is given below, and please also refer to the disclosed diagrams and figure numbers:

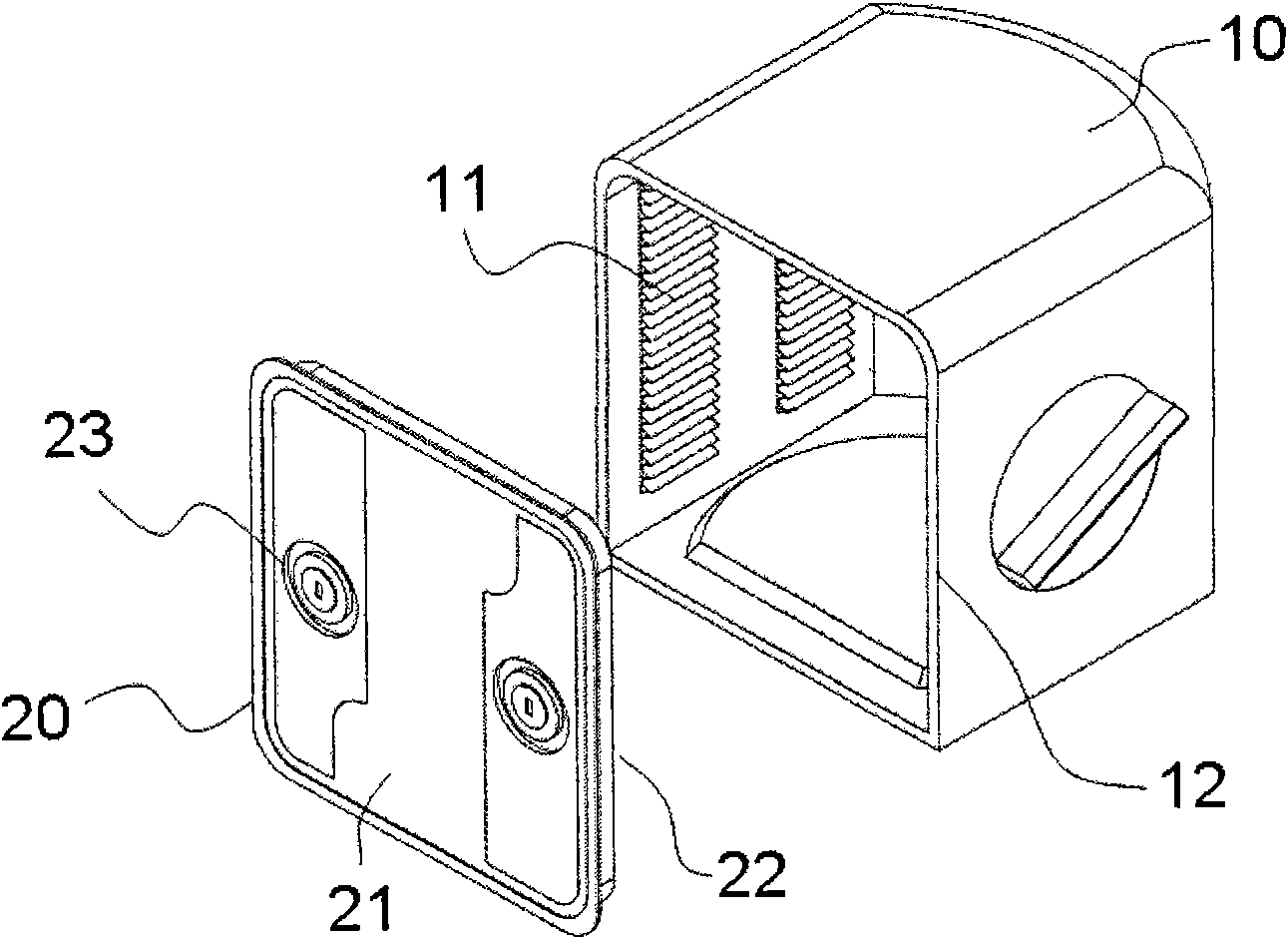

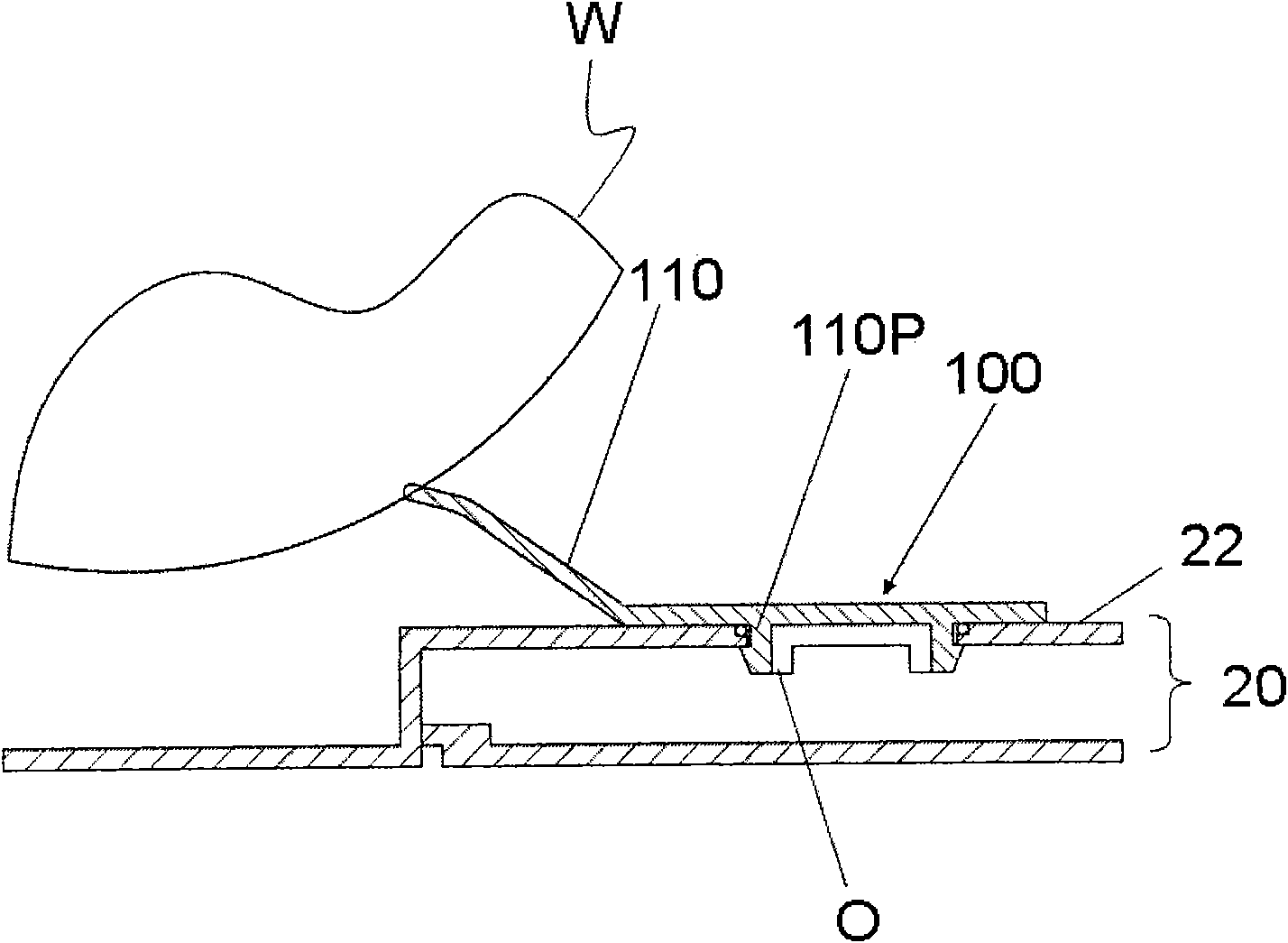

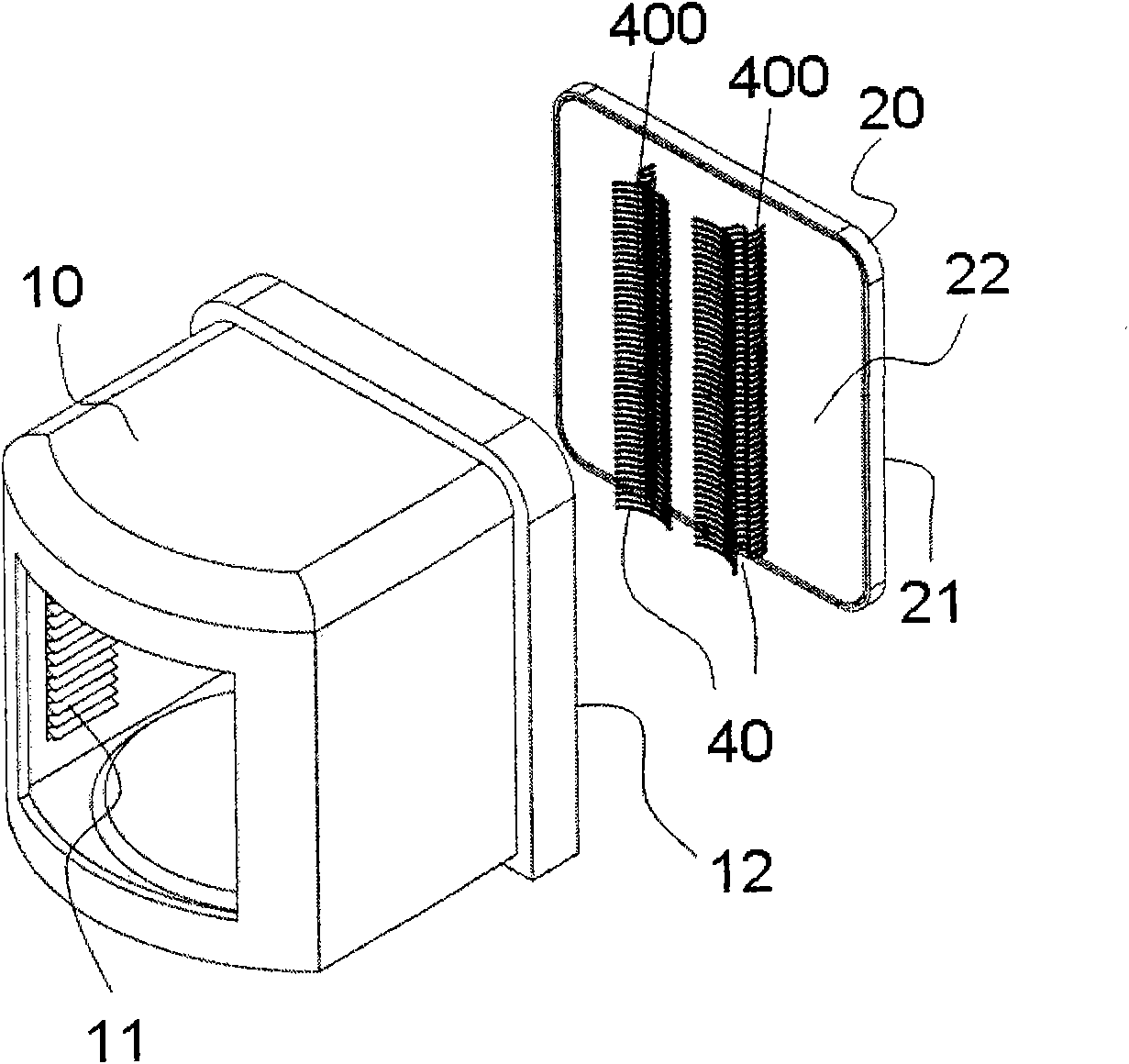

[0053] First, see image 3 Shown is a schematic diagram of the first wafer box of the present invention. This wafer box is a front-opening type wafer box, which mainly includes a box body 10 and a door body 20. A plurality of slots 11 are provided inside the box body 10 to accommodate a plurality of wafers, and on the inside of the box body 10 One of the sides has an opening 12 to provide input and output of wafers, and the door body 20 has an outer surface 21 and an inner surface 22, and the outer surface 21 of the door body 20 is configured with at least one latch opening (not shown in the figure). ), which is used to open or close the front-opening wafer box, and two rows of wafer restraint modu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap