Automatic crimper capable of simultaneously threading water proof bolts to both ends of cable and crimping

A technology of waterproof plug machine and crimping machine, which is applied in the direction of circuits, connections, electrical components, etc., which can solve problems such as unsatisfactory, low efficiency, and increased labor intensity, so as to meet high-quality requirements, reduce production costs, and reduce labor. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

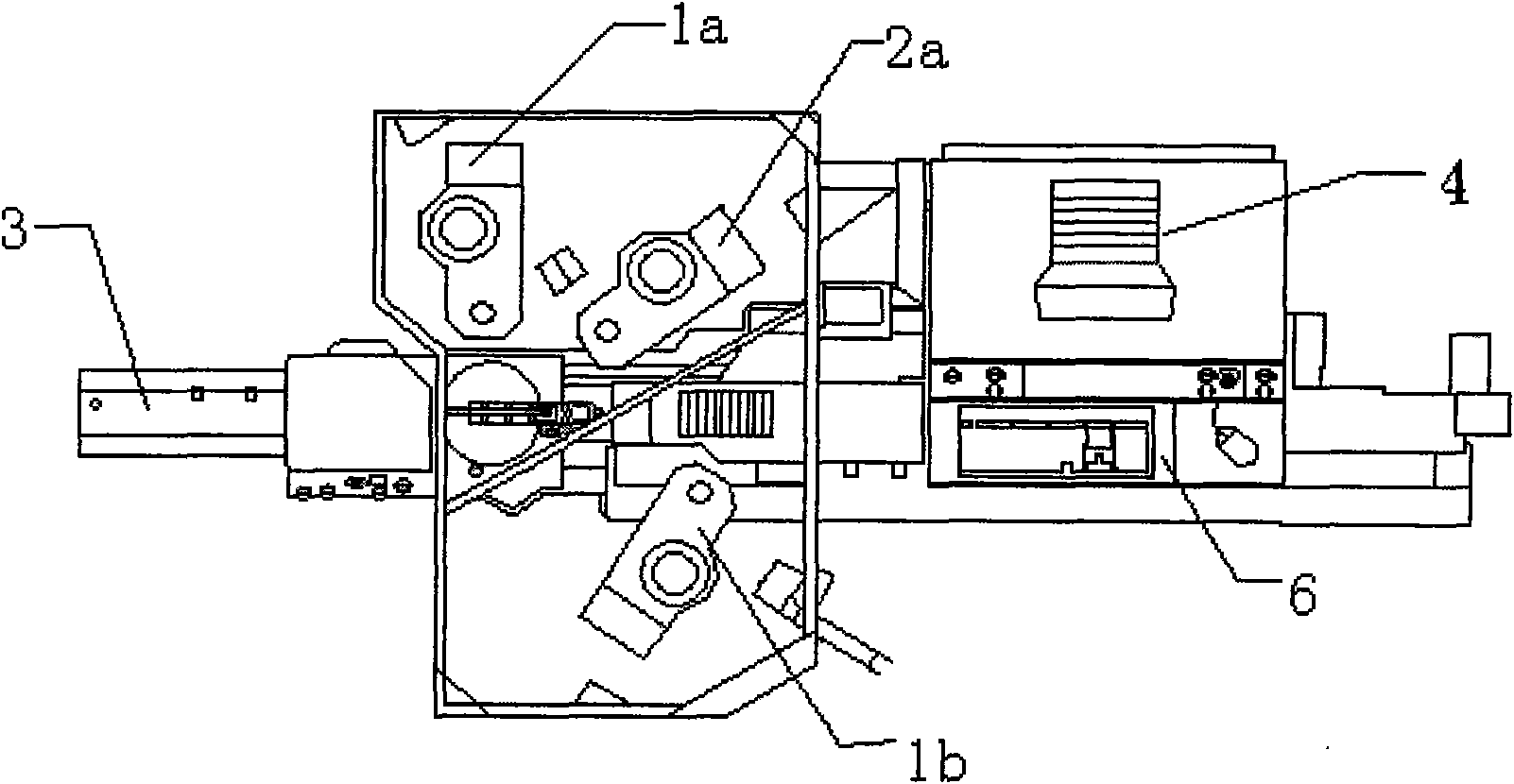

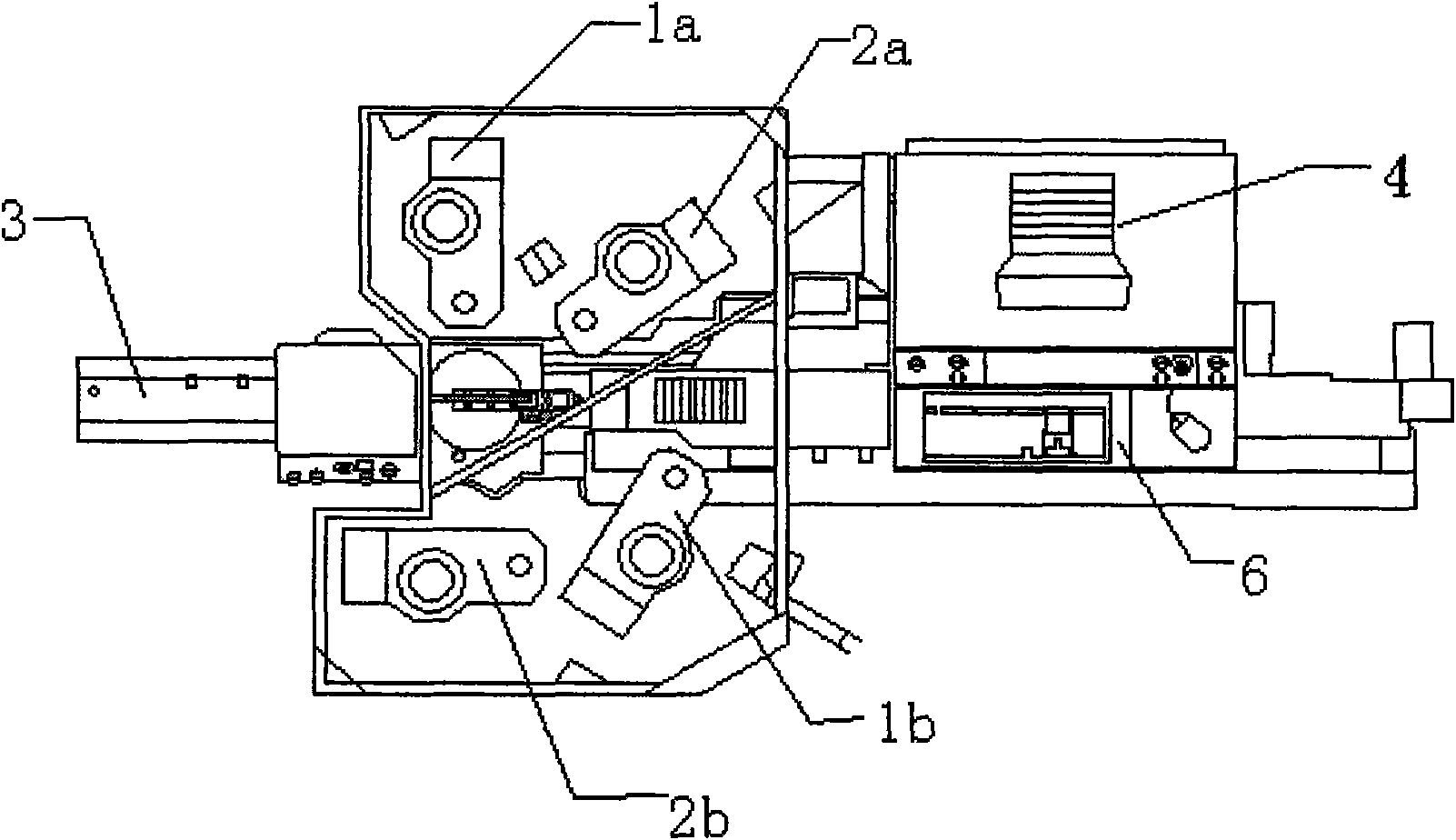

[0013] figure 1 Structural schematic diagram of an automatic crimping machine that puts waterproof plugs on and crimps traditional automotive wiring harnesses; figure 2 It is a structural schematic diagram of an automatic crimping machine that can simultaneously wear waterproof plugs on both ends of electric wires and crimp them according to the present invention.

[0014] An automatic crimping machine capable of piercing and crimping both ends of electric wires with waterproof plugs at the same time, including two action areas, the first zone and the second zone, and a crimping machine 1a and a waterproof plug-through machine 2a are arranged in the above-mentioned first zone, There is a crimping machine 1b in the second area, the crimping machine 1a in the first area is opposite to the crimping machine 1b in the second area, and there is also a waterproof bolt wearing machine 2b in the second area, which is connected with the waterproof bolt wearing machine in the first area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com