Multi-layer composite for use in an air filter

An air filter and composite technology, applied in the direction of membrane filter, filtration separation, dispersed particle filtration, etc., to achieve the effect of small thickness, high rigidity, and small unit area weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

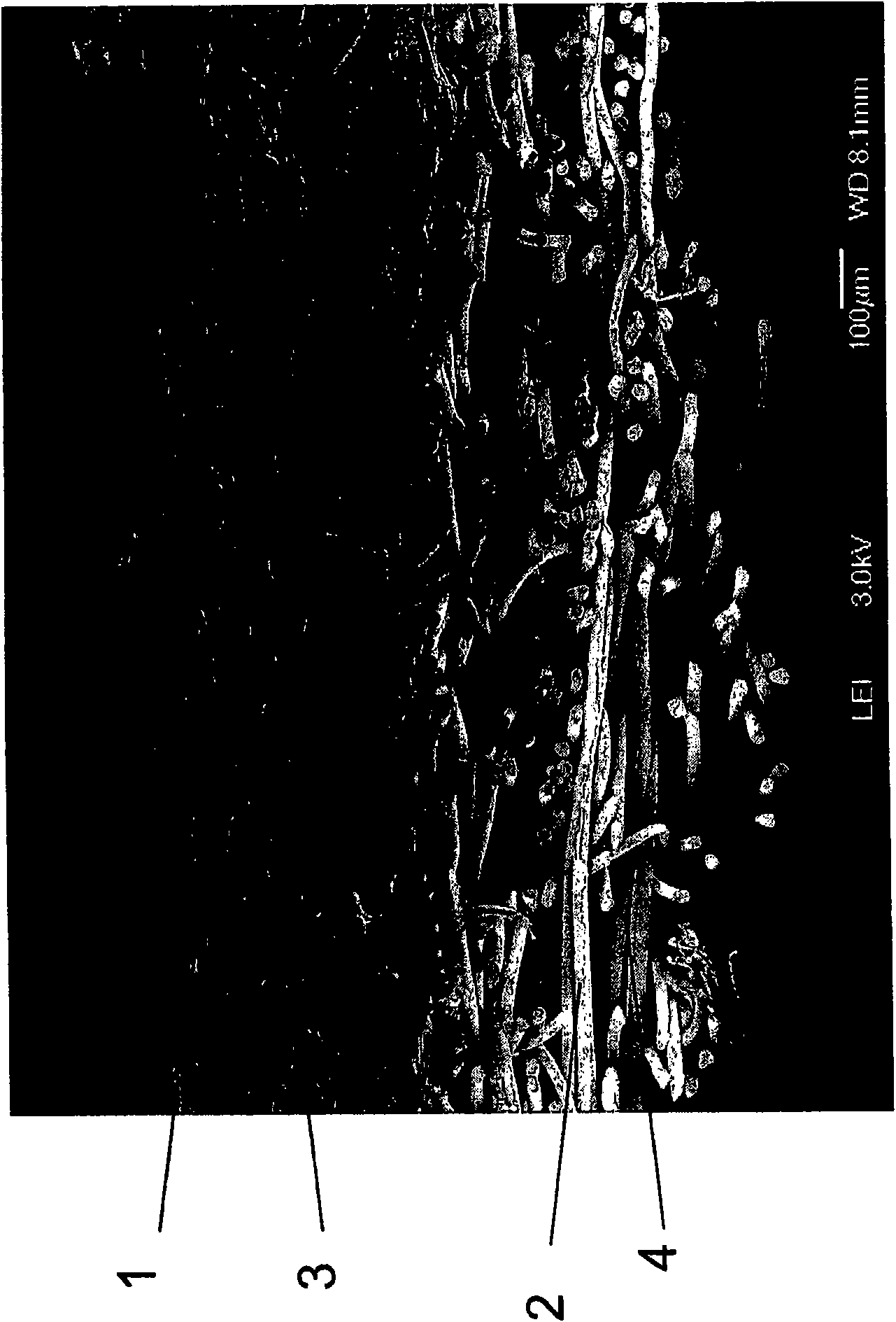

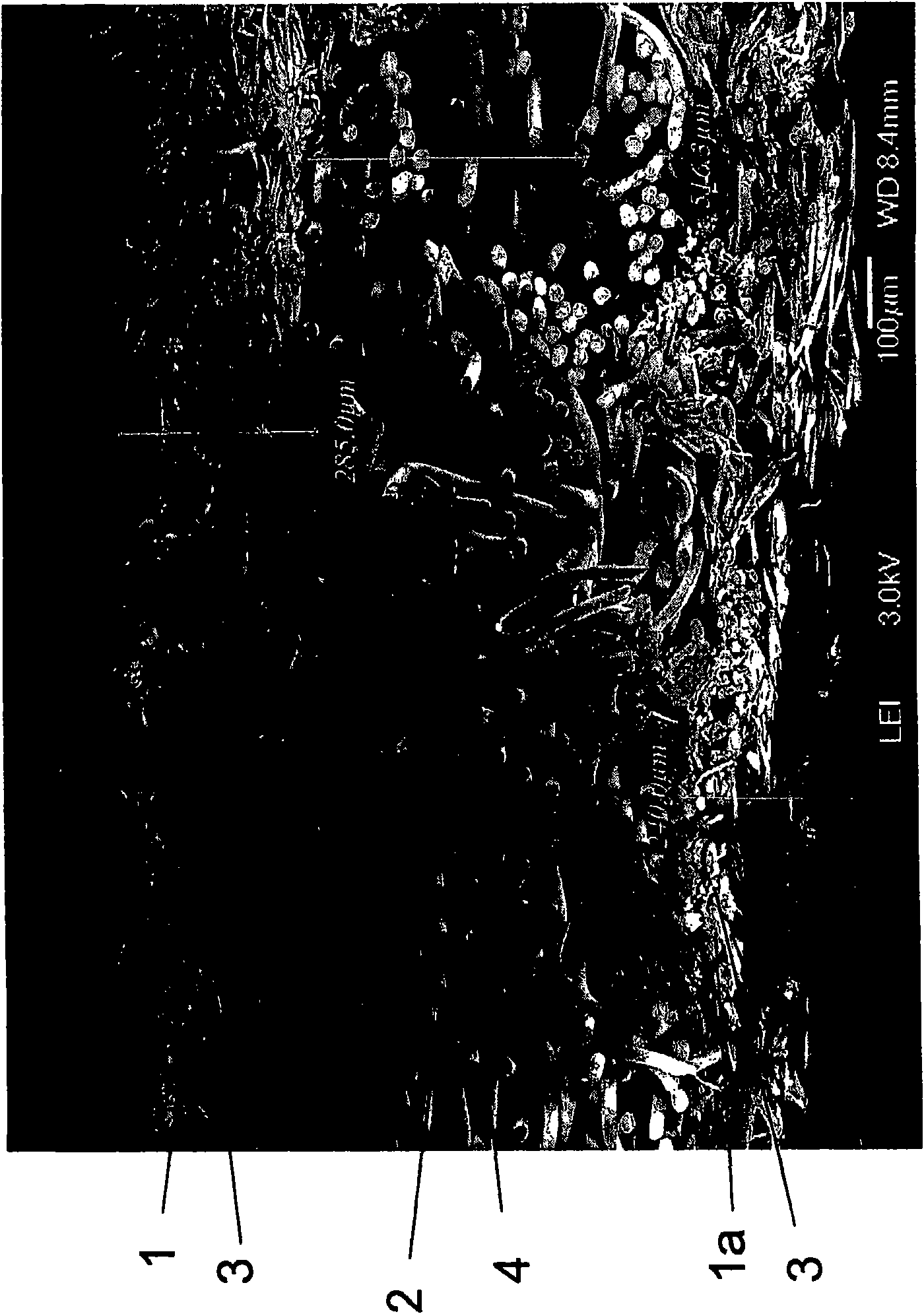

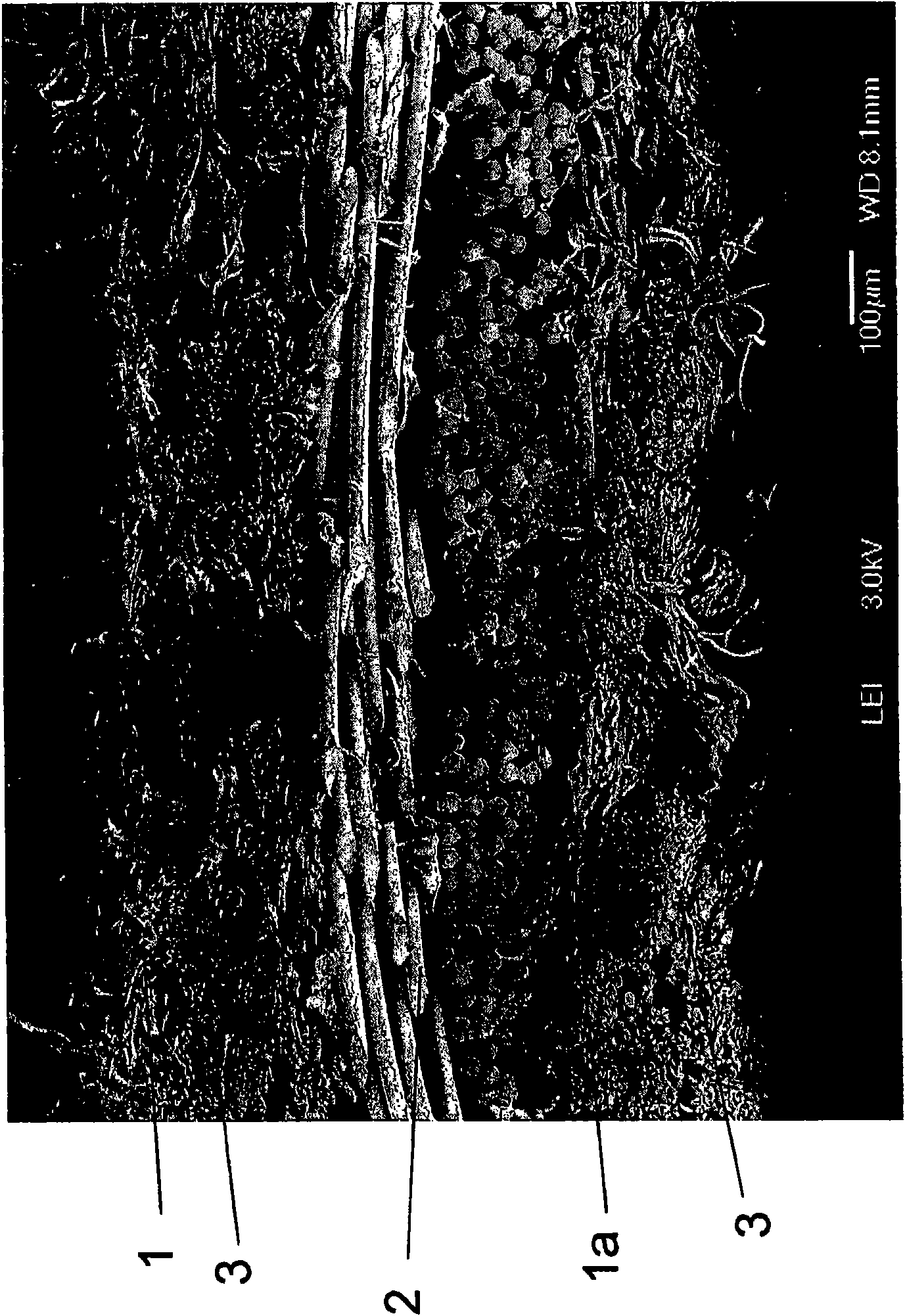

[0040] figure 1 Shown is a scanning electron microscope image of a multilayer composite for use in air filters, in particular filter bags, which has an inflow layer 1 made of a fleece. The inflow layer 1 has a finer porous structure than the support layer 2 . The inflow layer 1 is designed as a spunbonded fleece whose endless filaments 3 are at least partially interwoven or woven with the carrier layer 2 . The carrier layer 2 is designed as a spunbond fleece, the endless filaments 4 of which have a larger mean diameter than the mean diameter of the endless filaments 3 of the inflow layer 1 . The endless filaments 3 of the inflow layer 1 are interwoven with the support layer 2 by means of a water jet treatment. Both the inlet layer 1 and the support layer 2 are made of a spunbonded nonwoven produced by extrusion spinning.

[0041] The inflow layer 1 has endless filaments 3 with an average diameter of 0.3 μm to 10 μm. according to figure 1 The multilayer composite has 272g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com