Powder feeder, powder filling and packaging machine, and method of manufacturing powder package

A technology for supplying devices and filling packages, which is applied in the directions of automatic packaging control, packaging, and packaging protection. It can solve the problems of many wrong actions, difficulties, and large errors, and achieve the effect of realizing actions and suppressing wrong actions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0051] First, a powder supply device and a powder filling and packaging machine according to a first embodiment of the present invention will be described with reference to the drawings.

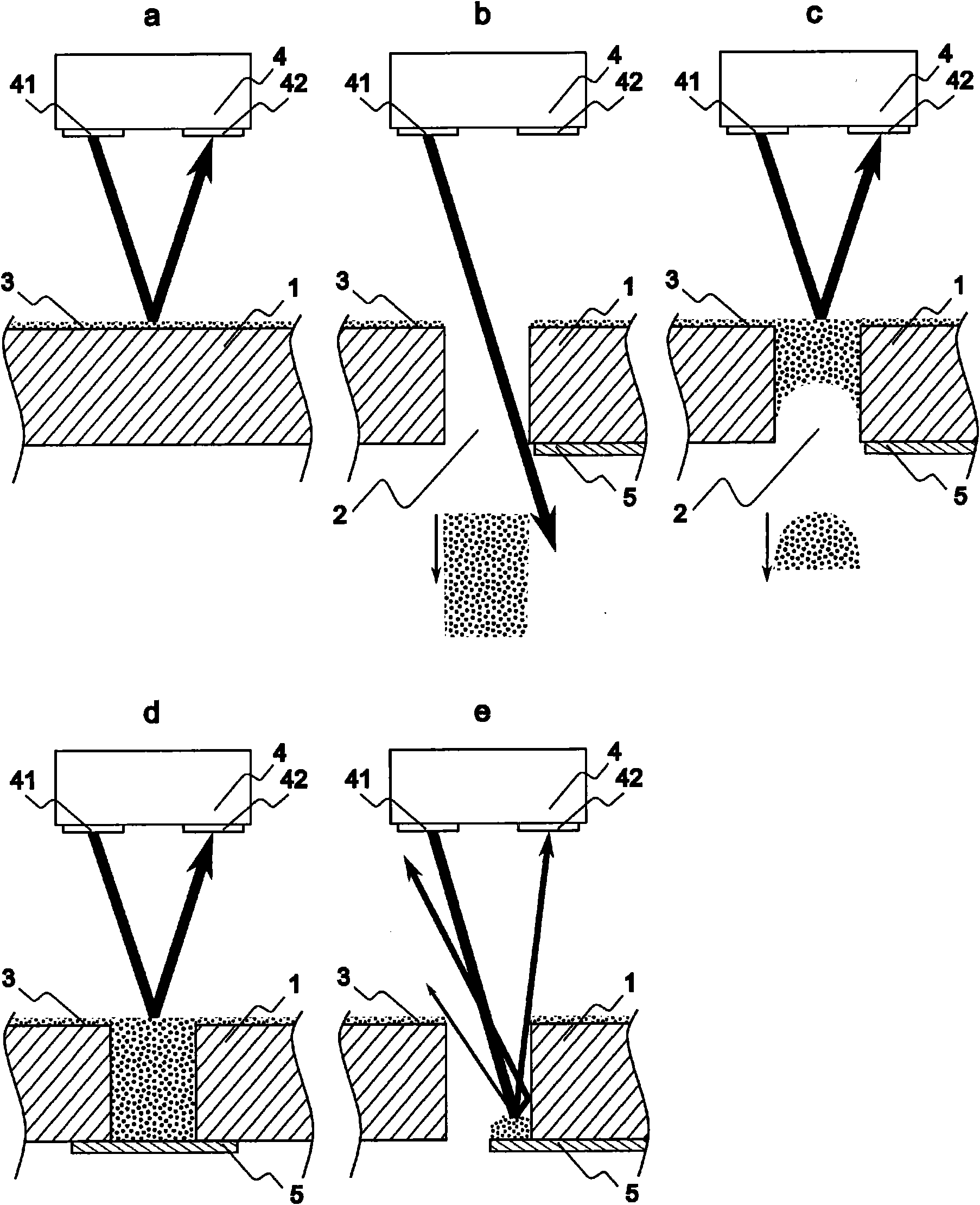

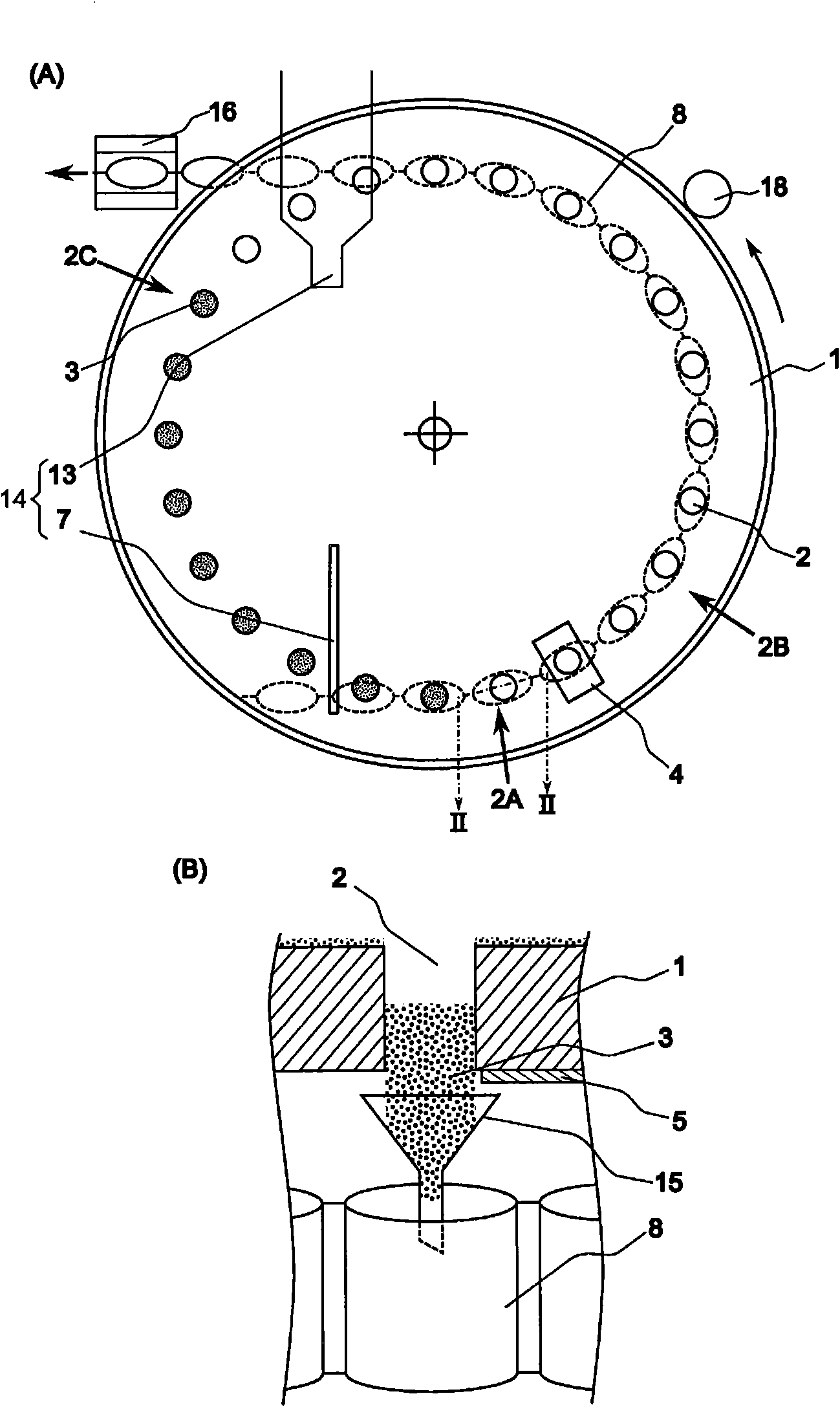

[0052] figure 1 It is a schematic cross-sectional view illustrating the state of filling and dropping powder into the hole of the plate-shaped part of the member, and explaining the state of light emission and light reception by the optical sensor (indicated by arrows). figure 2 It is a schematic diagram explaining the operation of a powder supply device and a powder filling and packaging machine using a rotary motion member. figure 2 A is a top view, figure 2 B is figure 2 Section view of line II-II in A.

[0053] Such as figure 2 As shown, the powder supply device includes: a component 1 with a hole 2 , a motion mechanism 18 for moving the component in a plane, an opening and closing part 5 , a powder filling part 14 , and an optical sensor 4 . In addition, the powder filling and...

no. 2 approach

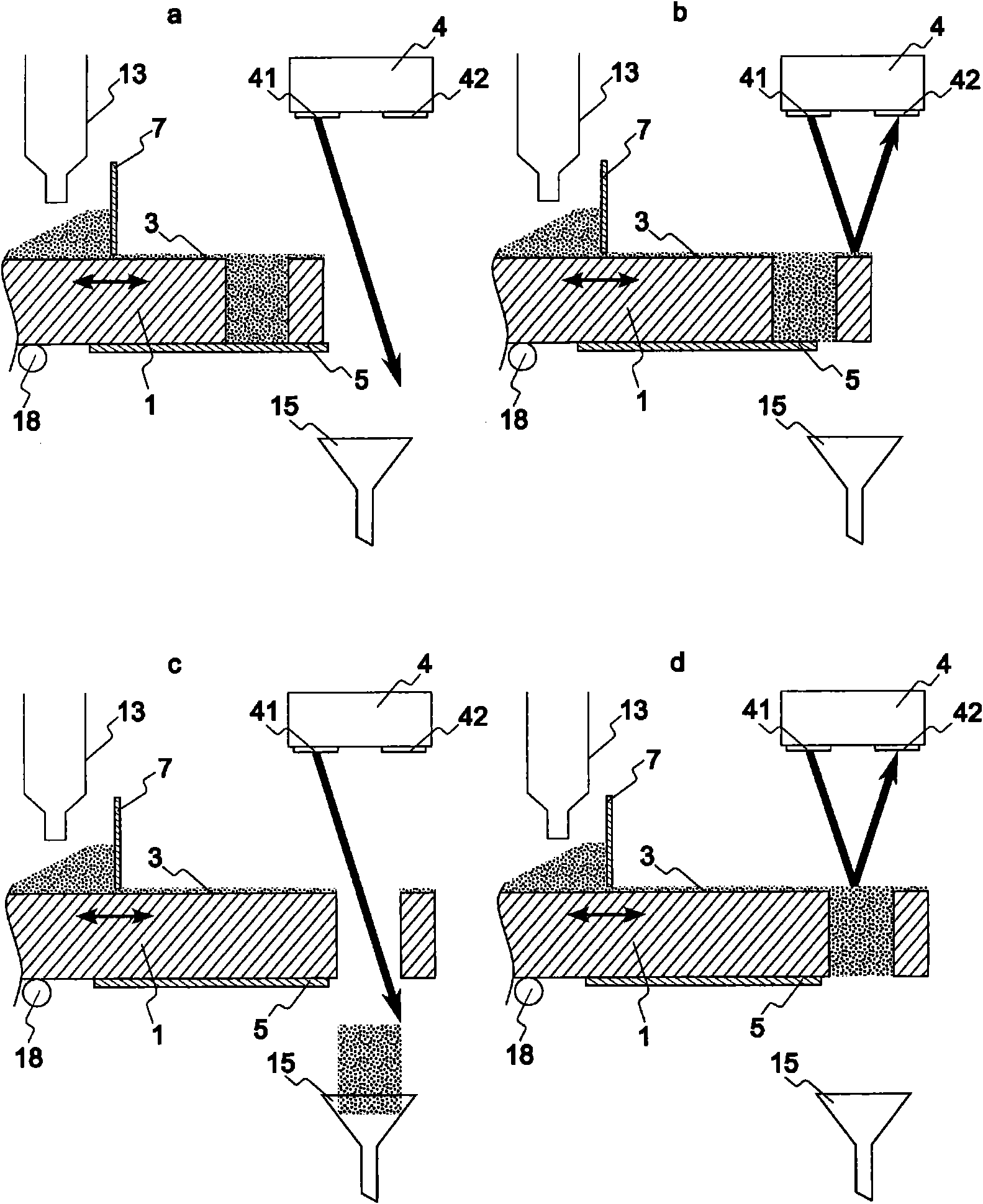

[0103] image 3 It is a diagram showing a powder supply device and a powder filling and packaging machine as the second embodiment of the present invention. When describing this embodiment, the same parts as those in the already described embodiment are denoted by the same reference numerals, and redundant ones are omitted. illustrate. The powder supply device and the powder filling and packaging machine according to the present embodiment will be described with respect to filling and dropping of the powder filling and packaging machine using a reciprocating plate-shaped member. In the present embodiment, the member 1 has a plate shape as a whole, so the member 1 is also called a plate member 1 . and, image 3 is a schematic cross-sectional view, and the optical sensor 4 is arranged directly above the position where the powder 3 falls.

[0104] image 3In a, the lower opening of the hole 2 is blocked, and the plate member 1 provided with the hole 2 functioning as a measuri...

Embodiment 1

[0119] This example uses figure 2 The powder filling packaging machine shown in the first embodiment whose basic structure is shown in FIG. However, the installation position of the kinematic mechanism 18 is different. In addition, in this embodiment, the member 1 used the plate member which has the hole 2 which each passes through on two concentric circles of an inner circle and an outer circle on the main surface. There are 24 through holes 2 on the inner circle and the outer circle respectively. The diameter of the through hole 2 for the inner circle is about 3mm, and the diameter of the through hole for the outer circle is about 8mm. components. Here, the powder filling unit 14 capable of measuring two types of powder is arranged for the inner circle and the outer circle, and forms a powder filling and packaging machine for the deoxidizer.

[0120] The louver opening and closing cam is provided in such a way that after passing through the metering scraper 7, the louver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com