Fischer-tropsch derived diesel fuel and process for making same

A technology of fuel and diesel, applied in the field of preparing the fuel, can solve the problems of being unsuitable for commercial diesel fuel and failing to meet the cloud point specification of diesel fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

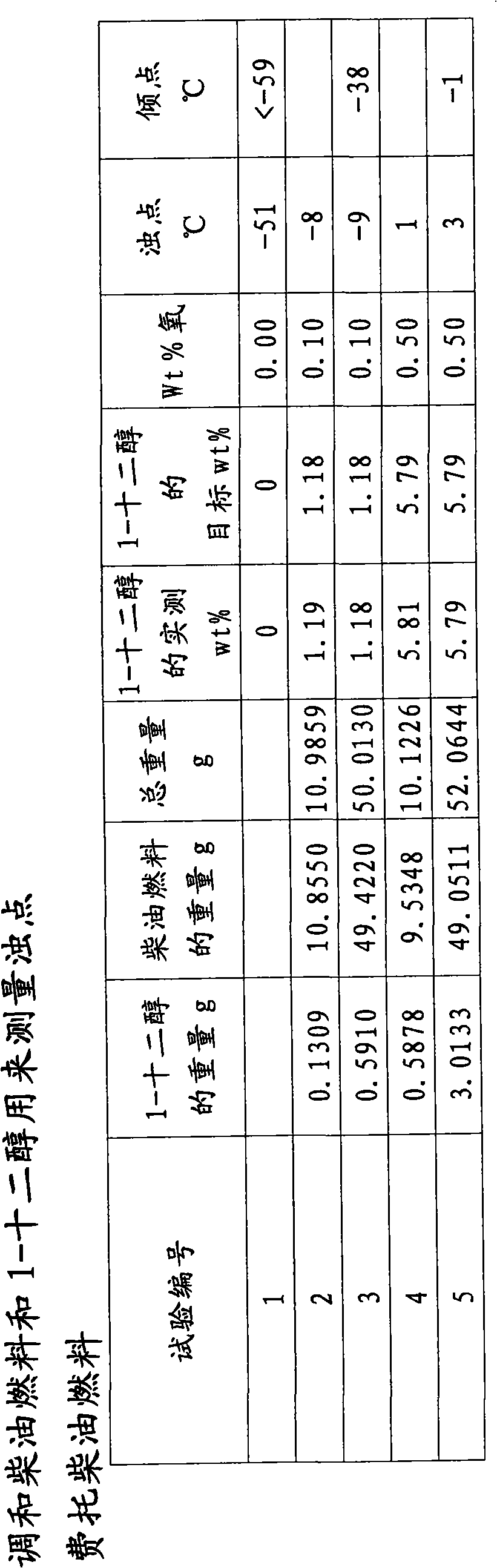

[0039] In this example, a Fischer-Tropsch diesel fuel with a high iso / normal ratio and an end point of 600°F (315°C) as measured by ASTM D2887 was prepared and tested.

[0040] Fischer-Tropsch C from Moore and Munger 80 Commercial sample of wax. It has an initial boiling point of 790°F as measured by ASTM D 2887 and a boiling point of 856°F at 5 wt%. It was hydrocracked in a single stage demonstration plant at 669°F, 1.0 LHSV, 1000 psig, 10000 SCF / Bbl hydrogen at about 90% conversion in single pass operation (no recycle). A commercially available sulfided hydrocracking catalyst was used. The 260-600°F product was recovered by distillation with the following properties. The product contains more than 2 wt% n-C 14+ Normal paraffins, but still have a cloud point of -51 °C.

[0041] Density at 15°C, g / ml

0.7626

Sulfur, ppm

0

Viscosity at -20°C, cSt

6.382

freezing point, ℃

-47.7

cloud point, ℃

-51

Flash ...

Embodiment 2

[0049] Additional diesel fuel samples with end points of 675°F (357°C) and 450°F (232°C) and intermediate iso / normal ratios were prepared and tested as follows. This sample meets the end boiling point and flash point requirements of ASTM D975 for No. 2-D fuels.

[0050] Samples of Fischer-Tropsch condensate and wax were produced from the cobalt catalyst. At 3.36 LHSV, 1000 psig total pressure, 5000 SCFB recycle gas ratio in vulcanized commercially available monolithic extrudate non-acid NiMo / Al 2 o 3 The condensate is hydrotreated over the catalyst. In vulcanized commercial monolithic extrudate acidic NiW / Al at 1.2 LHSV, 66% conversion per pass, 1000 psig total pressure, 5000 SCFB recycle gas ratio below 675°F (357°C) 2 o 3 -SiO 2 The wax is hydrocracked over the catalyst. The products from the two plants were continuously mixed and distilled. Materials boiling above the diesel cut point (approximately 675°F-357°C) are recycled to be consumed in the hydrocracker.

[00...

Embodiment 3

[0060] The diesel product from Example 2 was further distilled to obtain a 250-400°F (121-204°C) diesel fuel fraction that mimics No. 1-D fuel with these properties.

[0061] nature

[0062] nitrogen

[0063] These studies show that the addition of small amounts of dodecanol has a significant detrimental effect on cloud point. Addition of as little as 0.01 wt% oxygen as 1-dodecanol results in a cloud point (°C as measured by ASTM D2500) well above the lowest cloud point limit of -49°C. Join C 5 -C 10 Alcohols do not cause a significant increase in cloud point. All wt % oxygen concentrations mentioned above are measured on an anhydrous basis.

[0064] Preferably with 1-C 5 to 1-C 10 The FT diesel alcohol composition is exemplified below.

[0065] FT diesel with 1-heptanol

[0066]

[0067] FT diesel with 1-pentanol

[0068]

[0069] FT diesel with 1-dodecanol

[0070]

[0071] FT Diesel with 1-Decanol

[0072] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com