Housing for a turbomachine

A fluid machinery and casing technology, applied in the field of turbomachinery casings, can solve problems such as steam or hot gas leakage, and achieve the effects of reducing temperature sensitivity, reducing manufacturing costs, and reducing space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

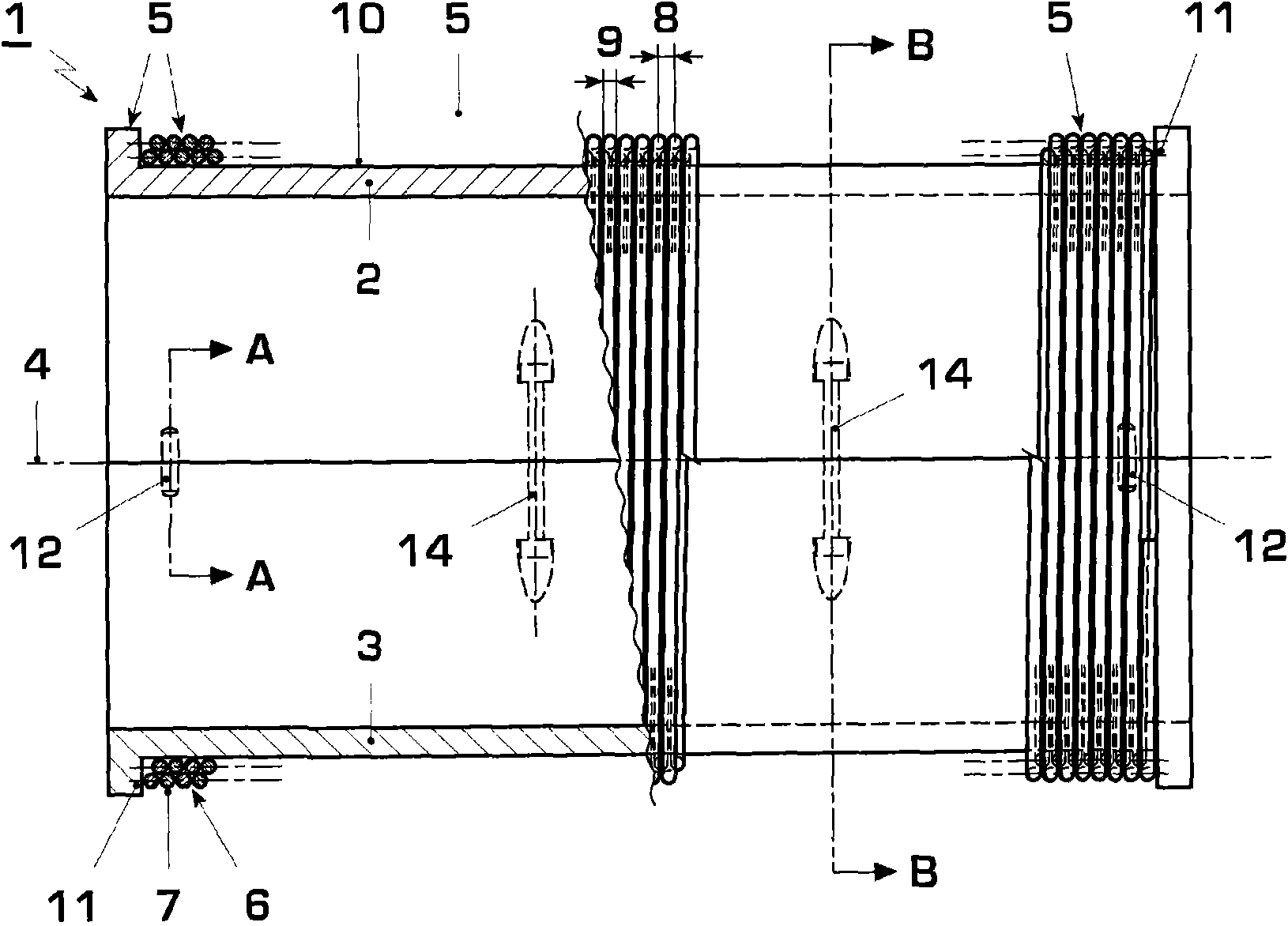

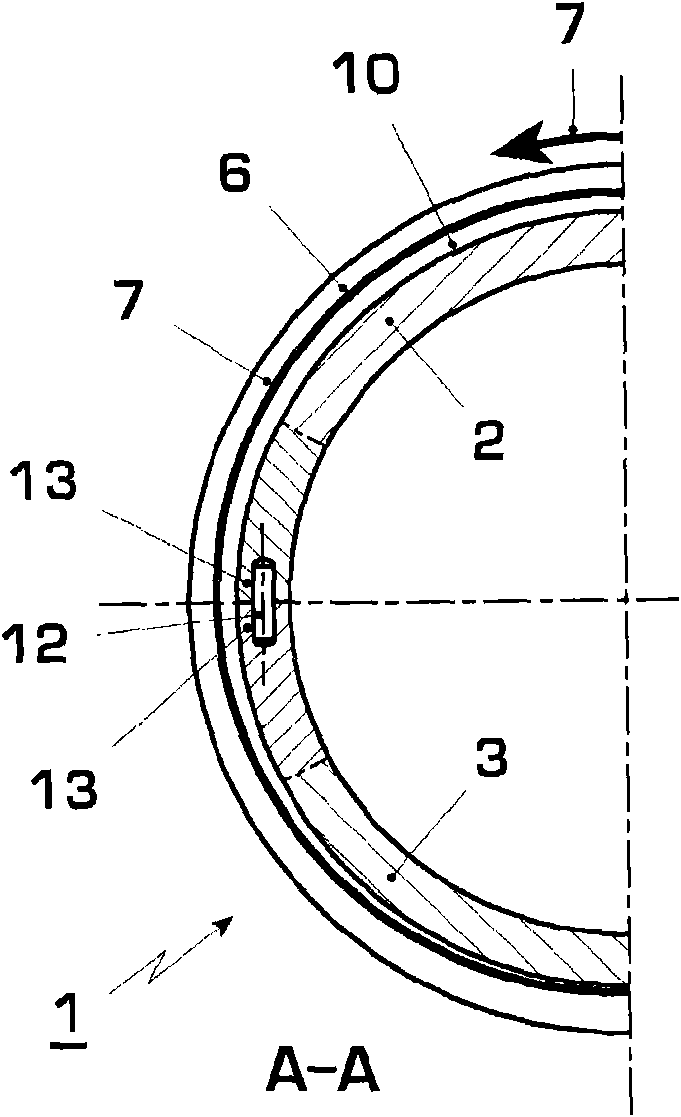

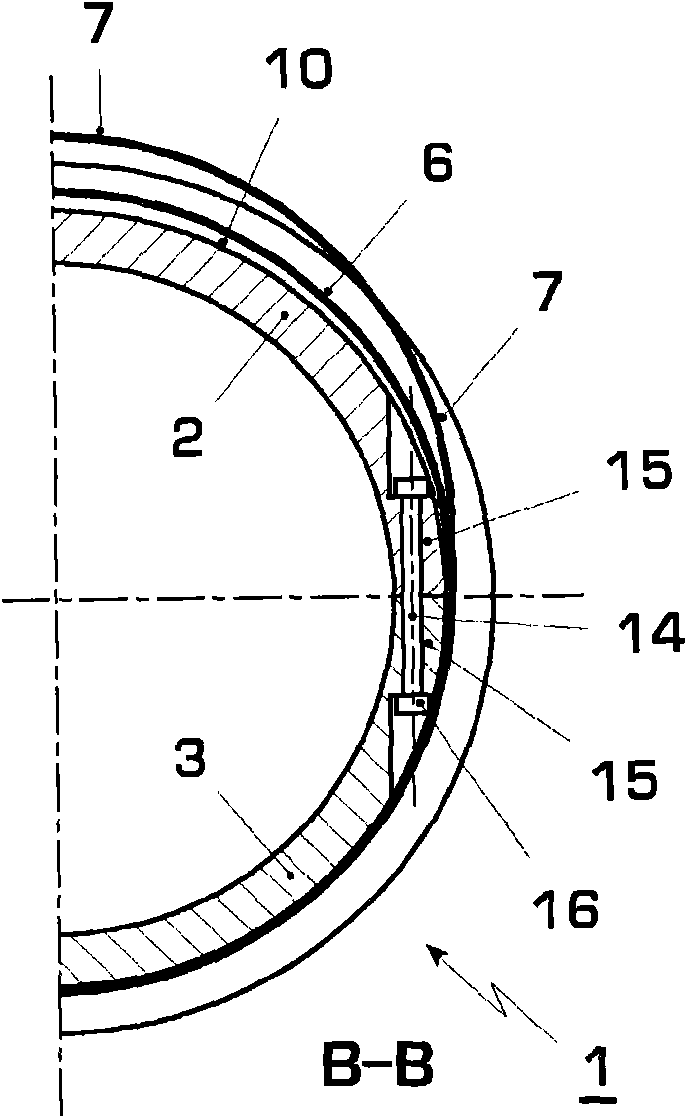

[0026] according to figure 1 , the housing 1 of the turbomachine, whose remaining parts are not shown, comprises two housing halves 2 , 3 , namely in particular an upper housing half 2 and a lower housing half 3 . The two housing halves 2 , 3 bear against one another at an axial boundary 4 , whereby the housing 1 is closed in the circumferential direction. Furthermore, the housing 1 includes a fastening device 5 which is designed in such a way that the two housing halves 2 , 3 can be fixed to each other and can be prestressed relative to each other.

[0027] The aforementioned fastening device 5 has at least one coil 6 formed with at least one guy rope 7 . The coil 6 wraps around the two housing halves 2 , 3 at their outer sides. In this case, the winding takes place in the circumferential direction or helically. The helical winding 6 here expediently has a slope 8 corresponding to the rope thickness or rope diameter 9 . Other slopes 8 are also conceivable. The guyline 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com