Improved structure of cable bridge

A technology for cable trays and improved structures, which is applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of difficult manufacturing, complicated process, and inconvenient transportation, and achieve light overall weight, improve transportation efficiency, Ease of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

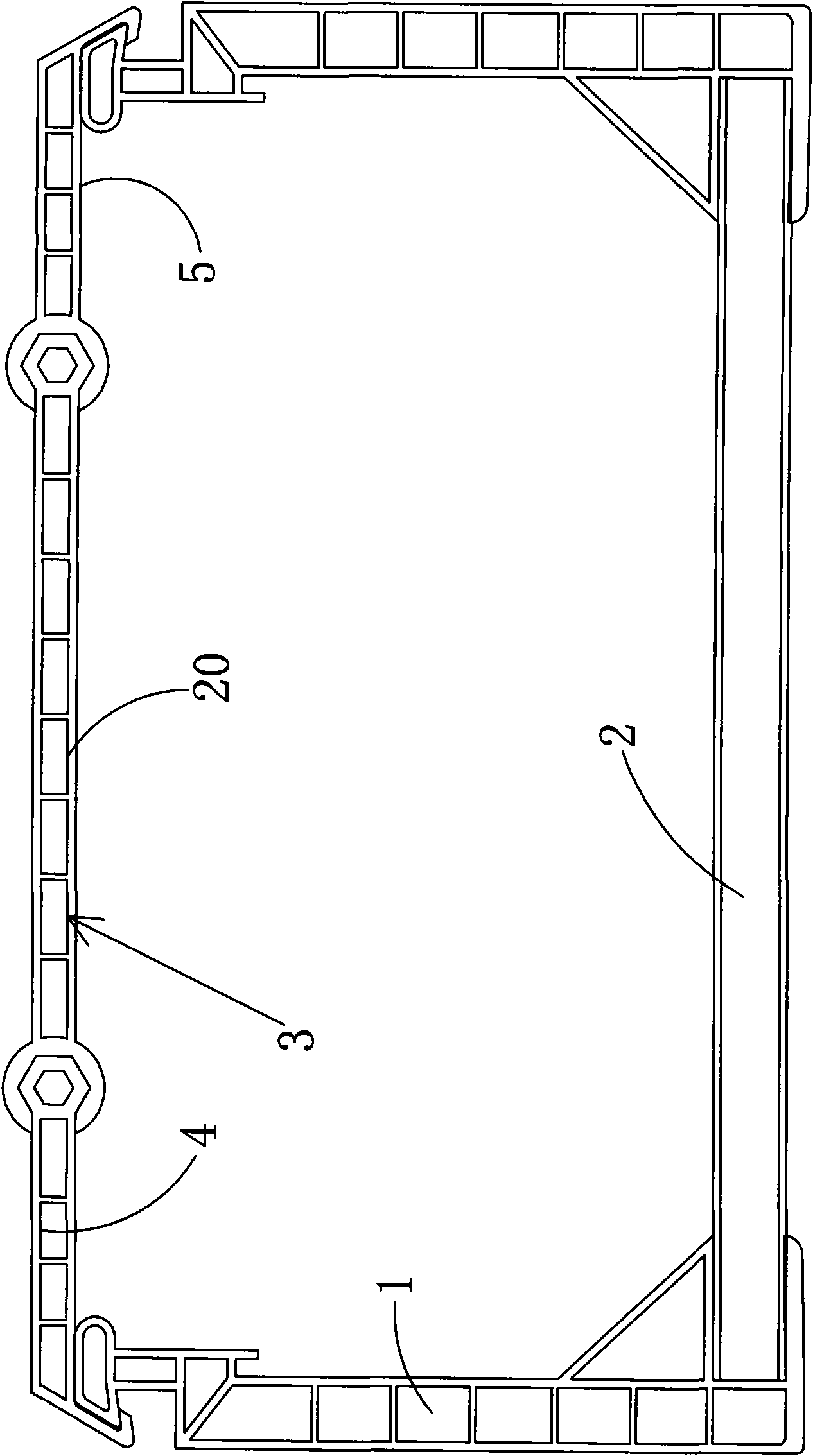

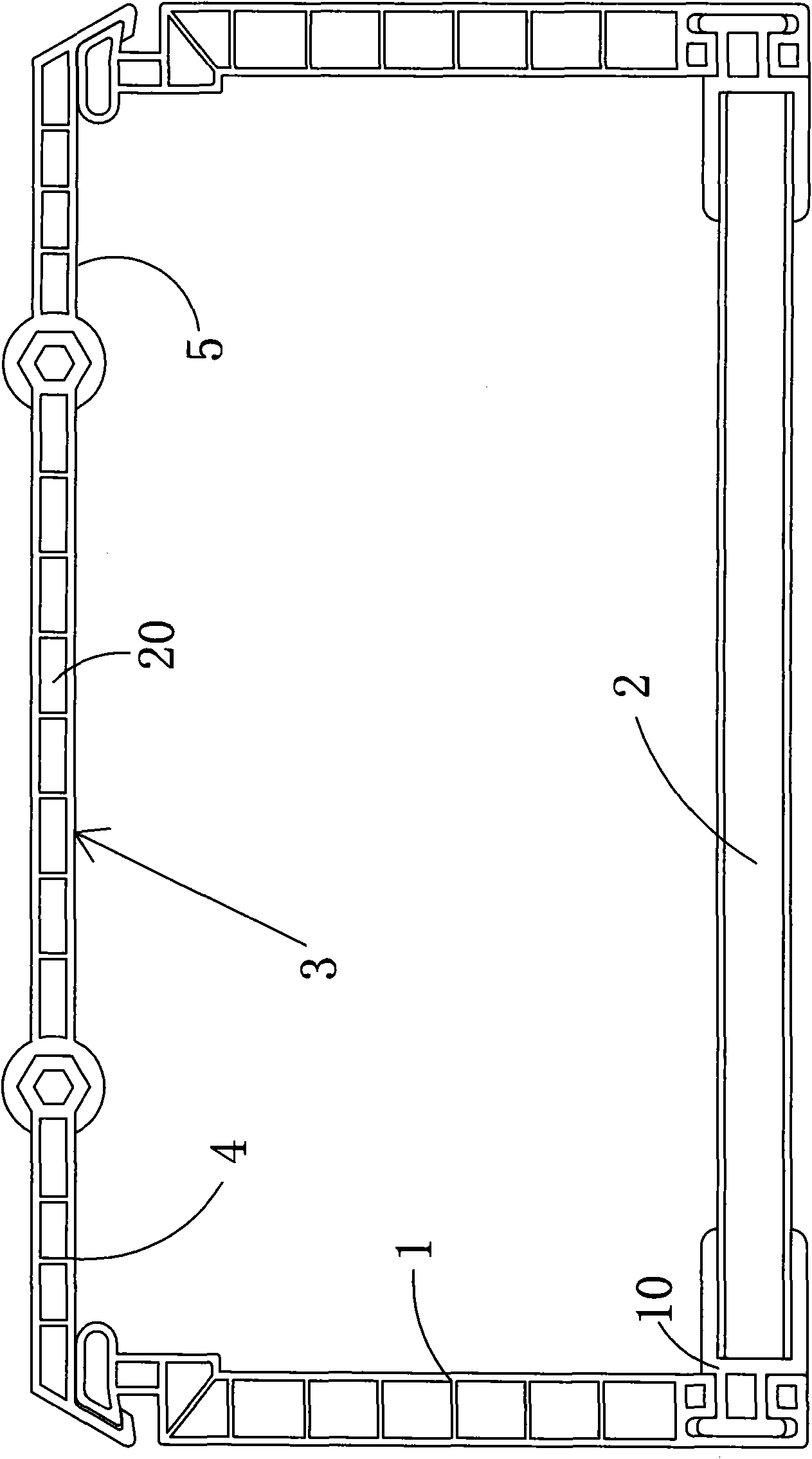

[0023] Embodiment: An improved structure of a cable bridge, including two side plates 1, a bottom plate 2 and a cover plate 3, the bottom plate 2 and the two side plates 1 are formed separately, and the two sides of the bottom plate 2 are respectively detachably fixed to the The bottom of the two side plates 1; the cover plate 3 includes first and second engaging plates 4, 5, wherein one side of the first engaging plate 4 is a convex portion 6, and one side of the second engaging plate 5 is a neck with an opening. The concave notch 7, the convex part 6 can be fixedly engaged in the concave notch 7, the other side of the first and second engaging plates 4, 5 forms a hook groove 8 toward the center of the cable tray, The top of the two side plates 1 is respectively provided with a groove 9 on the side away from the center of the cable tray, the hook groove 8 is fixedly engaged in the groove 9, and the bottom plate 2, the two side plates 1 and the cover plate 3 are all For engine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com