Lens system

A lens and lens technology, applied in the field of lens systems, can solve problems such as difficult correction of aberrations in lens systems, poor imaging quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

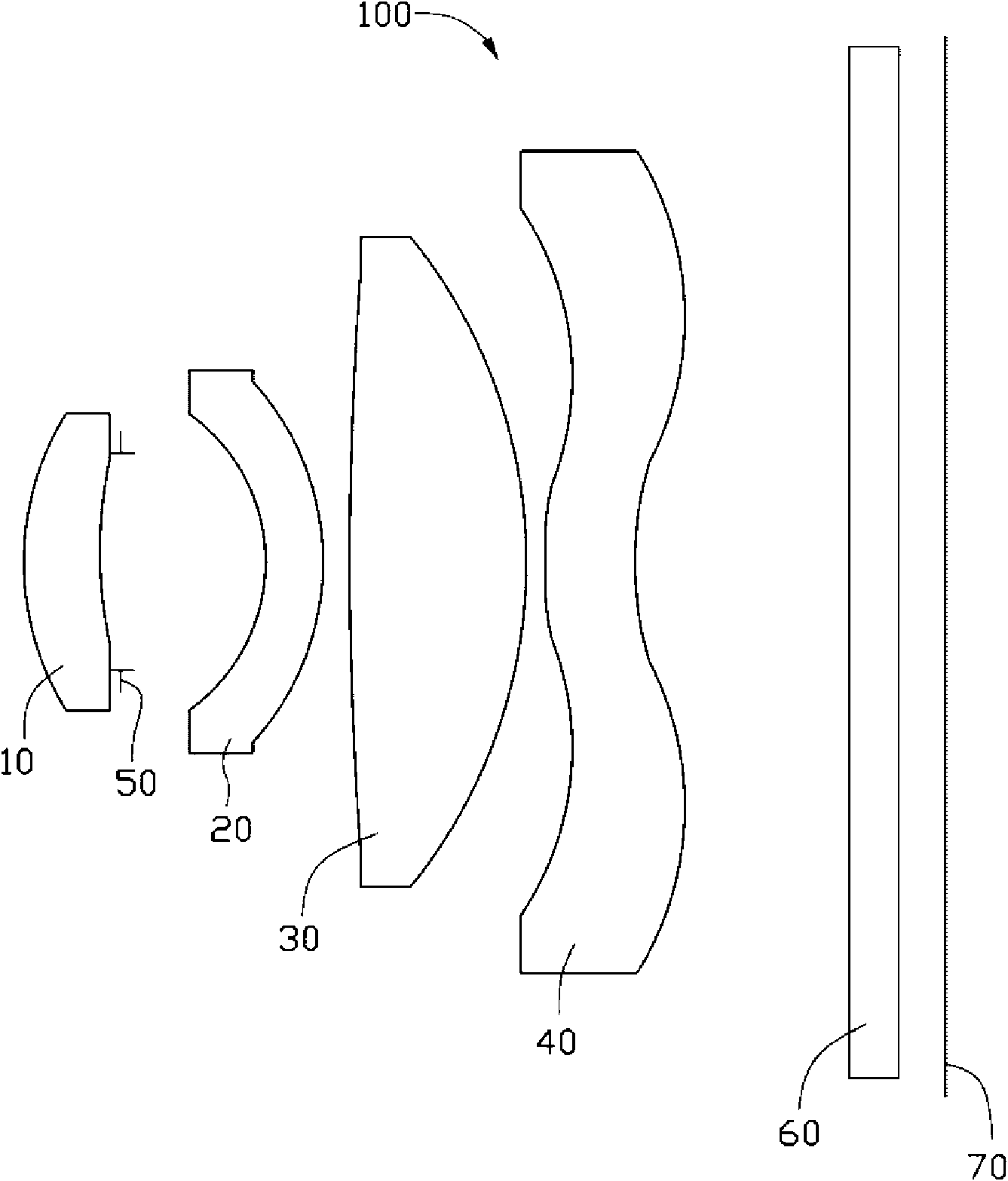

[0043] Each optical element of the lens system 100 satisfies the conditions in Table 1 and Table 2, and 2ω=74°.

[0044] Table 1

[0045]

[0046]

[0047] Table 2

[0048] the surface

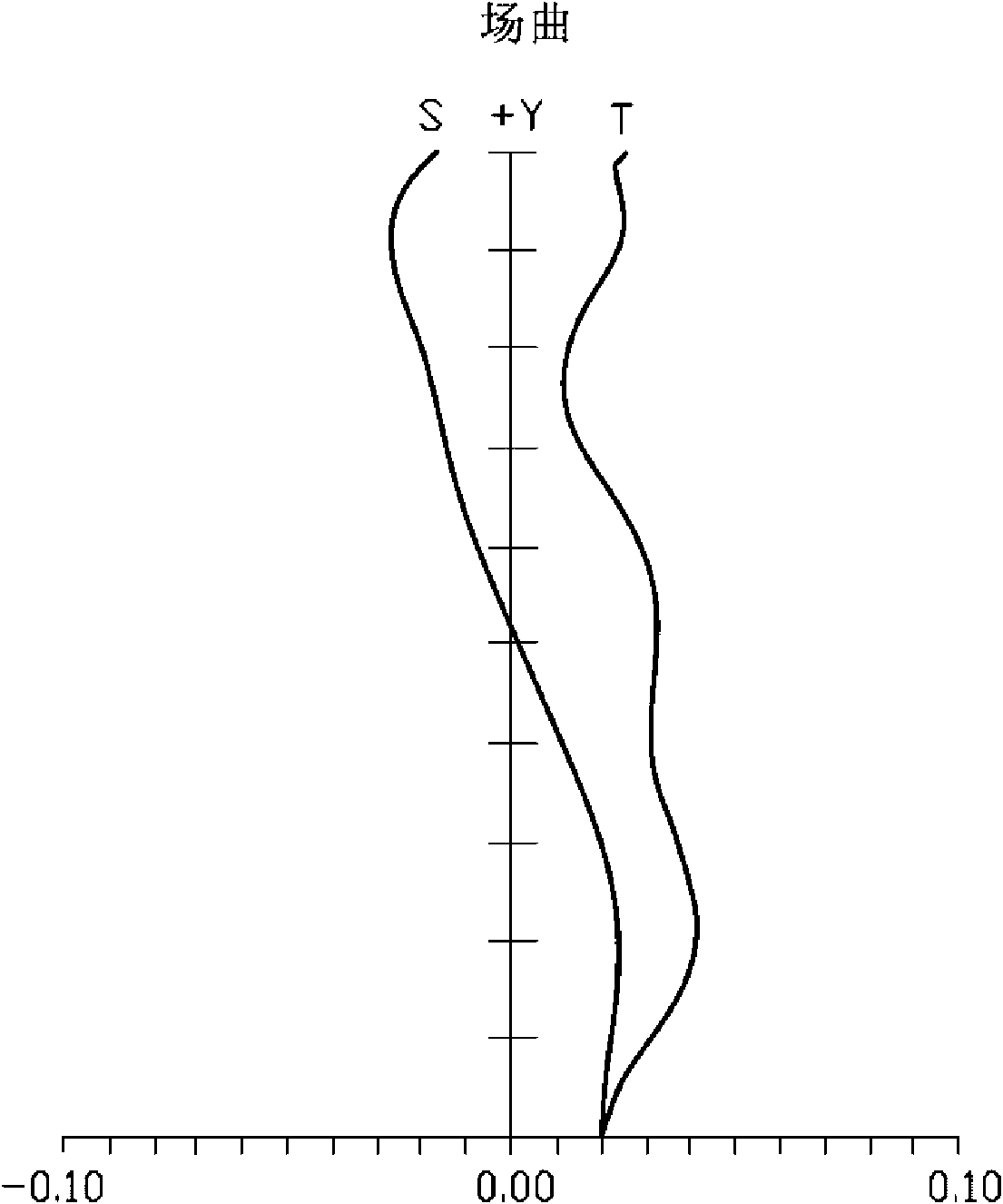

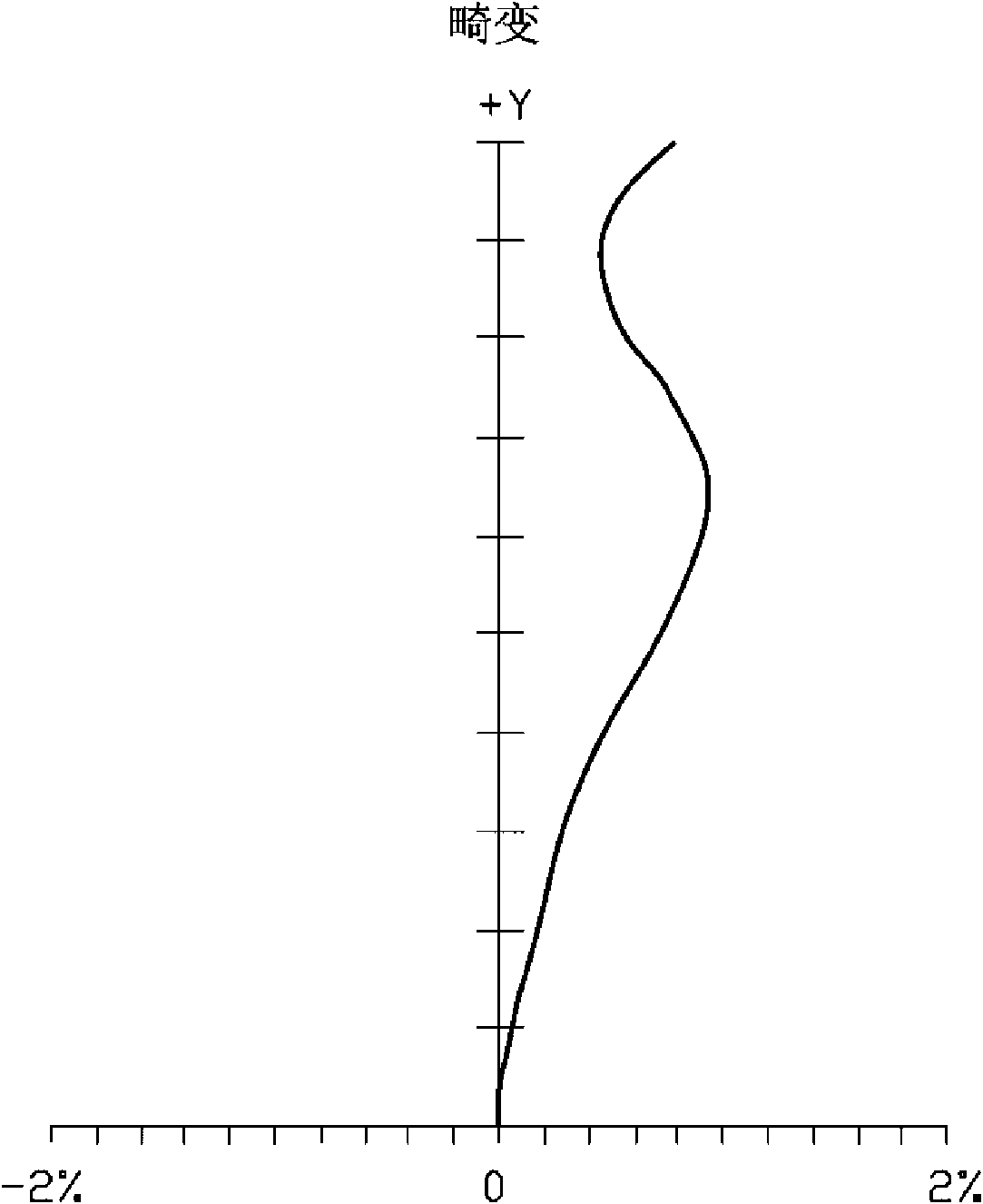

[0049] Field curvature, distortion and spherical aberration of the lens system 100 are as follows Figure 2 to Figure 4 shown. figure 2 The meridian field curvature and sagittal field curvature values are all controlled within the range of (-0.10mm, 0.10mm). image 3 The distortion rate is controlled in the range of (-2%, 2%). Figure 4 Among them, the spherical aberration values observed for f-line (value 435.8nm), d-line (value 587.6nm), and c-line (value 656.3nm) respectively. Generally speaking, the spherical aberration generated by the lens system 100 of this embodiment for visible light is within the range of (-0.05 mm, 0.05 mm). It can be seen that the aberration, field curvature and distortion of the lens system 100 can be well corrected.

no. 2 approach

[0051] Each optical element of the lens system 100 satisfies the conditions of Table 3 and Table 4, and 2ω=72°.

[0052] table 3

[0053] lens system 100

Radius of curvature (mm)

Thickness (mm)

The surface of the first lens 10 on the object side

1.406081

0.642755

1.543

56.803

The image-side surface of the first lens 10

3.657686

0.228189

-

-

The surface of the second lens 20 on the object side

1.25147

0.507969

1.632

23.415

The surface of the second lens 20 on the image side

2.54427

0.08

-

-

The surface of the third lens 30 on the object side

7.841619

0.822438

1.543

56.803

The surface of the third lens 30 on the image side

4.62433

0.206411

-

-

The fourth lens 40 is on the object side surface

1.810916

0.599514

1.632

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com