Aluminum electrolysis capacitor

A technology of aluminum electrolytic capacitors and electrolytic paper, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of no shunt in the current path, short-circuit breakdown of capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

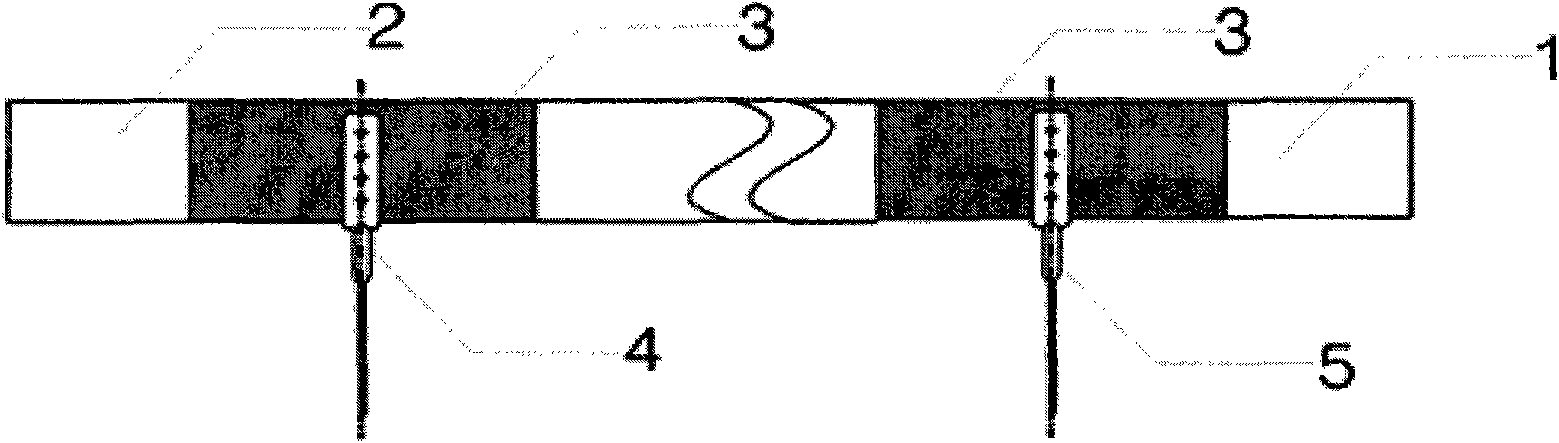

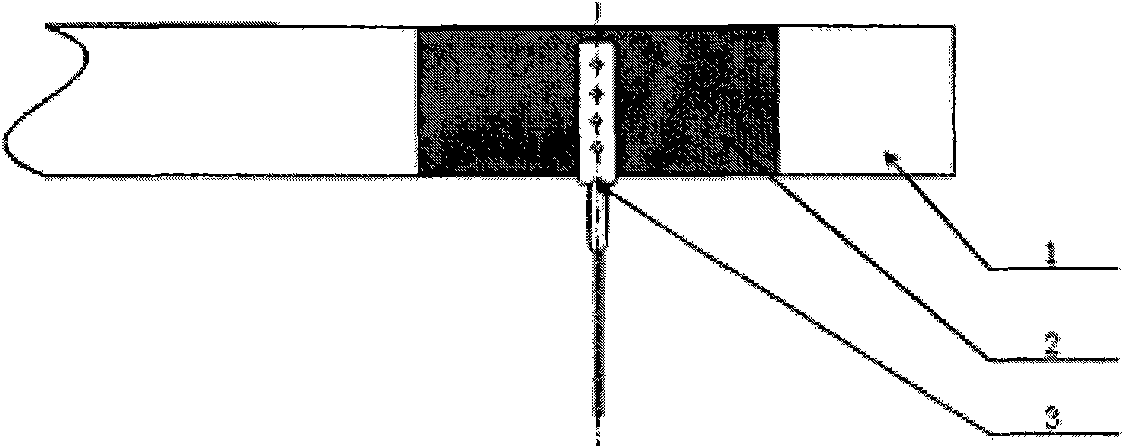

[0012] Such as figure 1 and 2 As shown, the present invention includes a positive electrode foil 2 with a positive electrode guide pin 4 riveted, a negative electrode foil 1 with a negative electrode guide pin 5 riveted, spread in the electrolytic paper between the two electrode foils, and the negative electrode foil of the aluminum electrolytic capacitor before winding 1. Riveting the negative electrode guide pin at 5 places and the positive electrode foil. The liner aluminum foil 3 is arranged on the front of the positive and negative electrode foils (2, 1), and the liner aluminum foil 3 is riveted under the positive and negative electrode guide pins (4, 5).

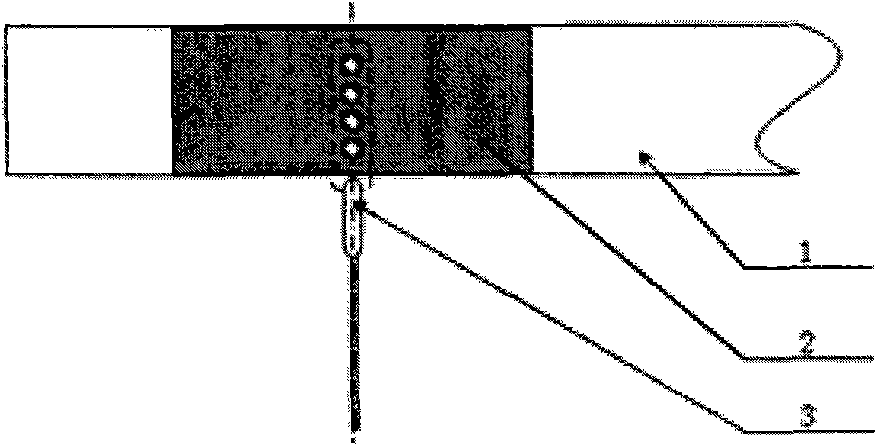

[0013] Such as image 3 As shown, another structure of the utility model is: the liner aluminum foil 3 is riveted on the back of the negative electrode foil 1, and is riveted on the back of the negative electrode guide pin 5 together with the negative electrode foil 1 .

[0014] For the same reason, the liner alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com