Fixed contact structure of disc high-current off-circuit tap-changer

A technology of tap changer and static contact, which is applied in the field of static contact structure, can solve the problems of affecting strength and rigidity, damaging the switch body, and low reliability, and achieves the effects of improving the electric field, reducing the height of the switch, and reducing the tip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

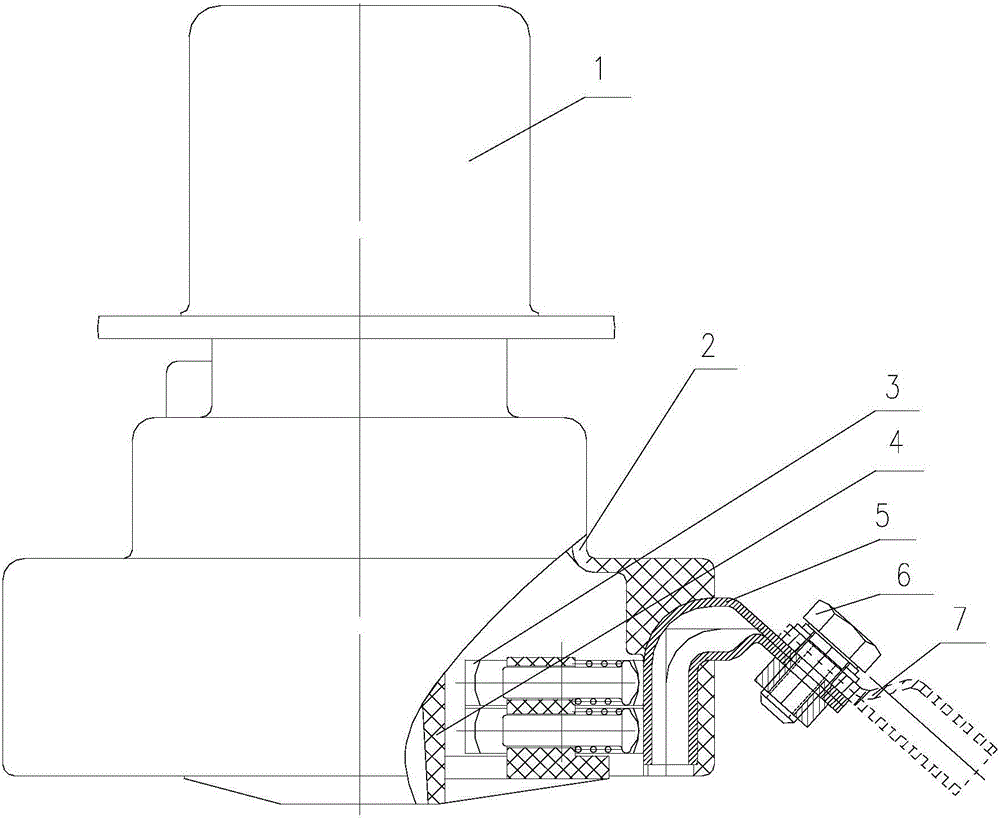

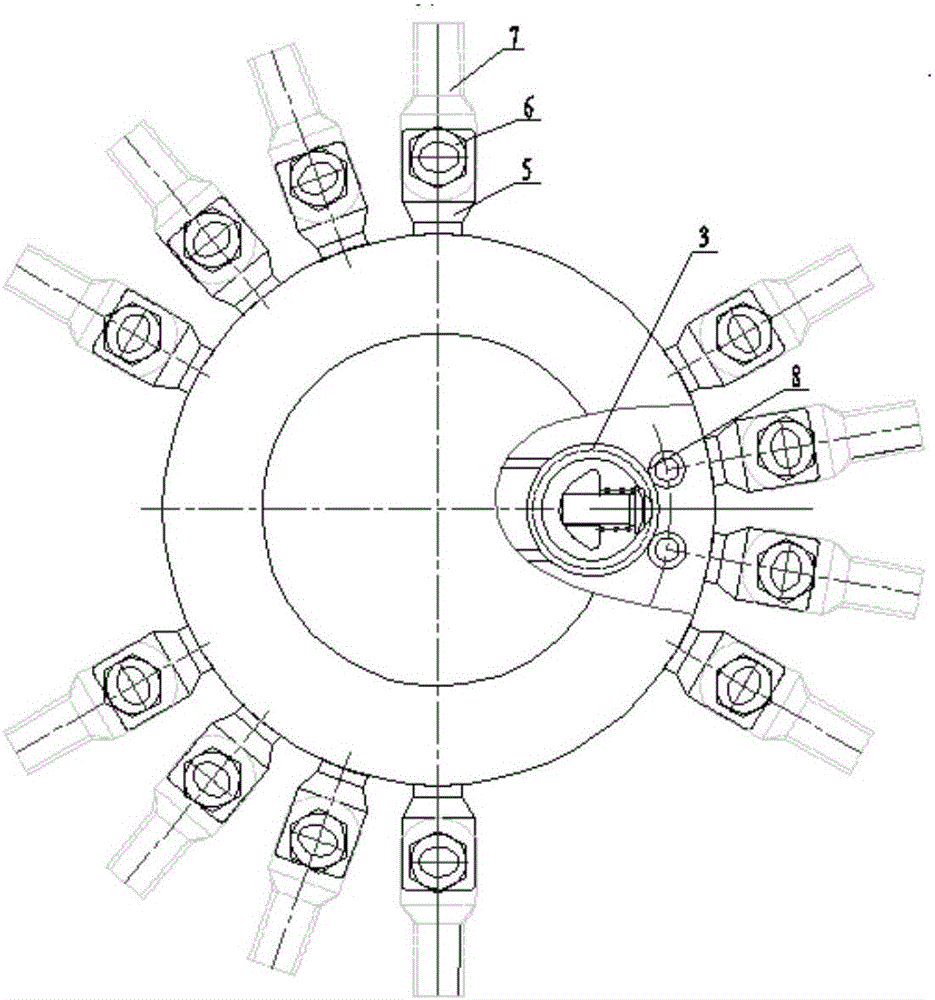

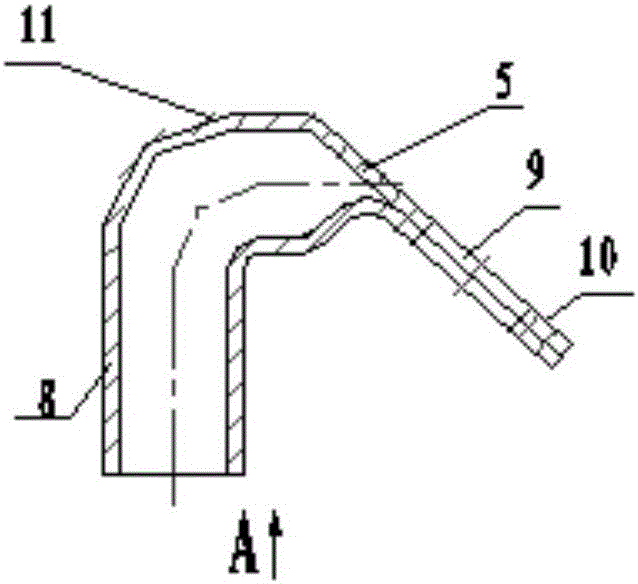

[0016] Such as Figure 1-2 As shown, this embodiment provides a static contact structure of a disc-shaped high-current non-excitation tap changer, including a switch base 2 and a rotating shaft 4 mounted on the switch base. The upper end of the rotating shaft 4 is connected to the operating positioning device 1, and the rotating shaft The lower end of 4 is equipped with a radial elastic rolling contact 3, and four sets of static contacts 5 are arranged at intervals of each phase in the circumferential direction corresponding to the radial elastic rolling contact 3 on the switch base. There are three phases in total. The static contacts 5 It includes a columnar static contact body 8 and a flat terminal 10. The static contact body 8 is configured with the radially elastic rolling contact 3. The upper end of the static contact body 8 is bent back downwards to form a wiring ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com