Grader having the cab mounted thereon

A cab and motor grader technology, which is applied in the field of motor graders, can solve the problems of obstructing the front view, the area of the front window becomes smaller, and the front view becomes worse, so as to achieve the effect of improving visibility and improving the front view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

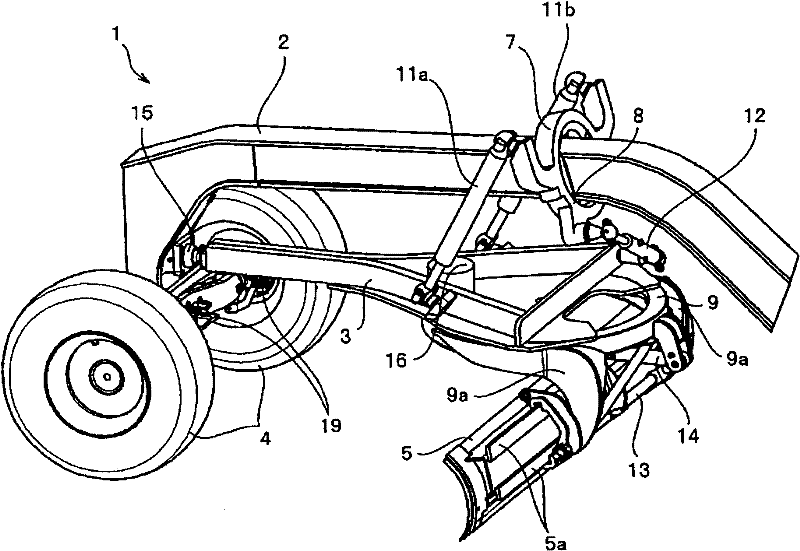

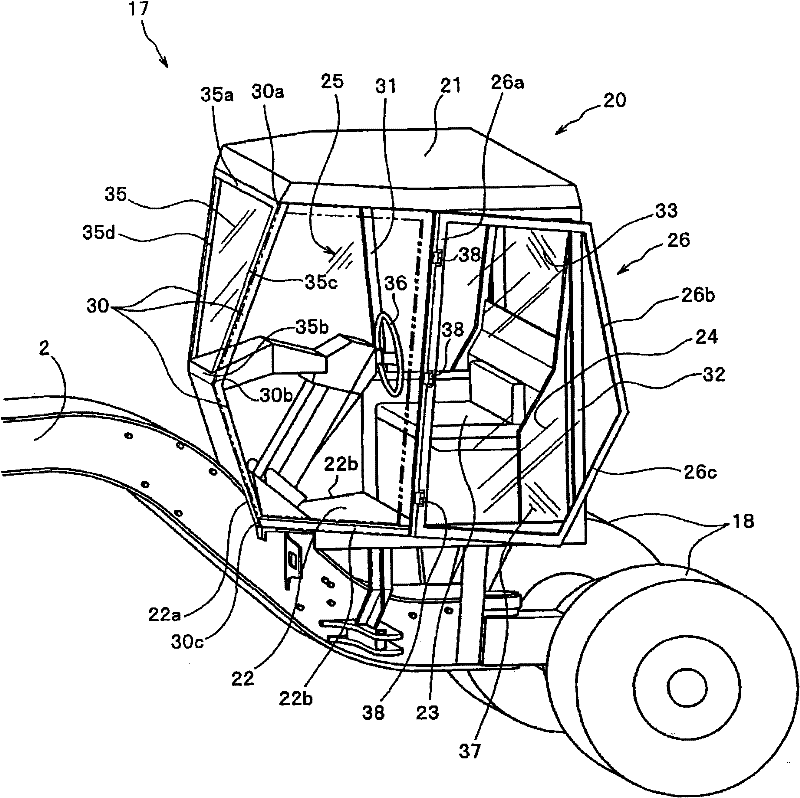

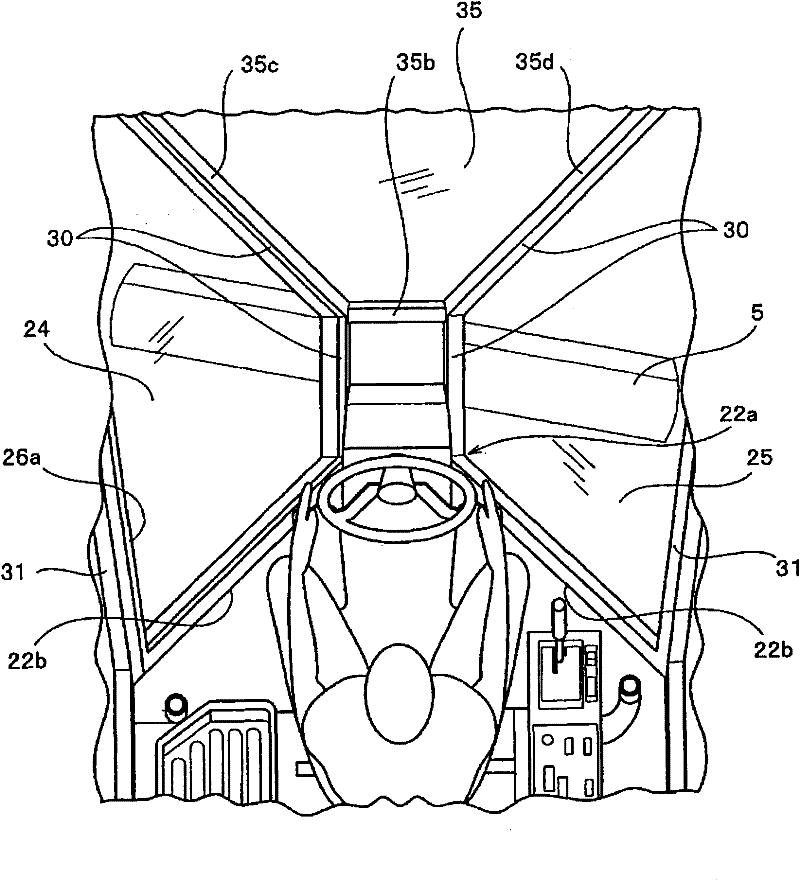

[0051] figure 1 It is an external view of the vehicle body front part of the motor grader 1 viewed from the side. That is, an external view of the front side of the front frame 2 of the motor grader 1 is shown. The appearance diagram of the operation part 17 of the car body rear portion is shown in figure 2 . In addition, the appearance of the scraper 5 viewed from the cab 20 through the floor 22 and the lower front window (32?) is given by image 3 The front perspective view of is shown.

[0052] On the front of the motor grader, such as figure 1 Shown, be provided with front wheel 4 and scraper 5 etc. that carry out operations such as cutting soil, at car body rear portion, as figure 2 Shown, be provided with rear wheel 18 and cab 20 etc. The front part of the car body is connected with the rear part of the car body through the front frame 2. Furthermore, the front frame 2 is connected to the rear part of the vehicle body, and can relatively rotate in the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com