Shoe press belt

A shoe press, polyurethane technology, applied in the press section, textiles, papermaking, paper machines, etc., can solve the problem of harsh use environment for shoe press belts, achieve excellent mechanical properties, improve wear resistance and durability. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

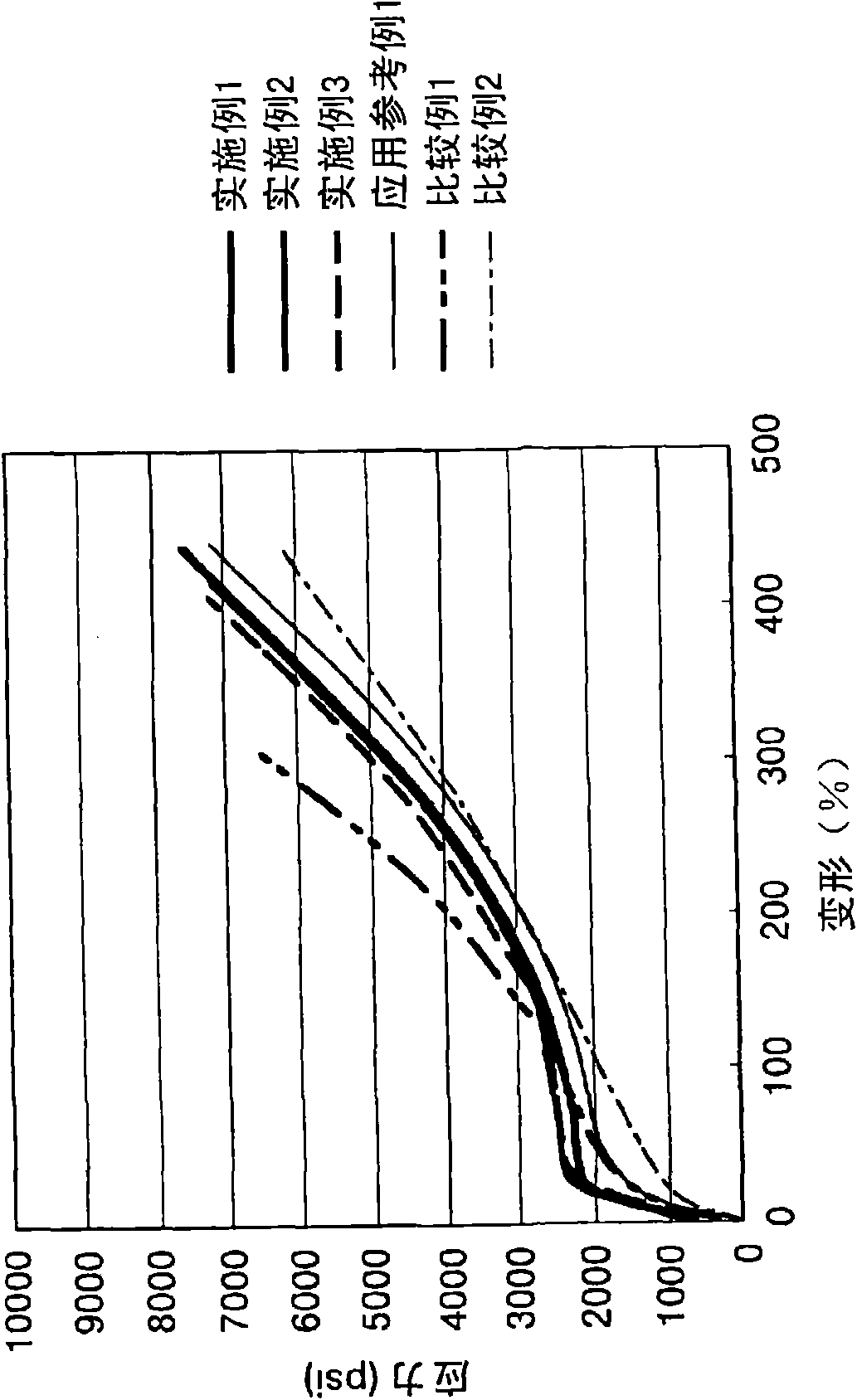

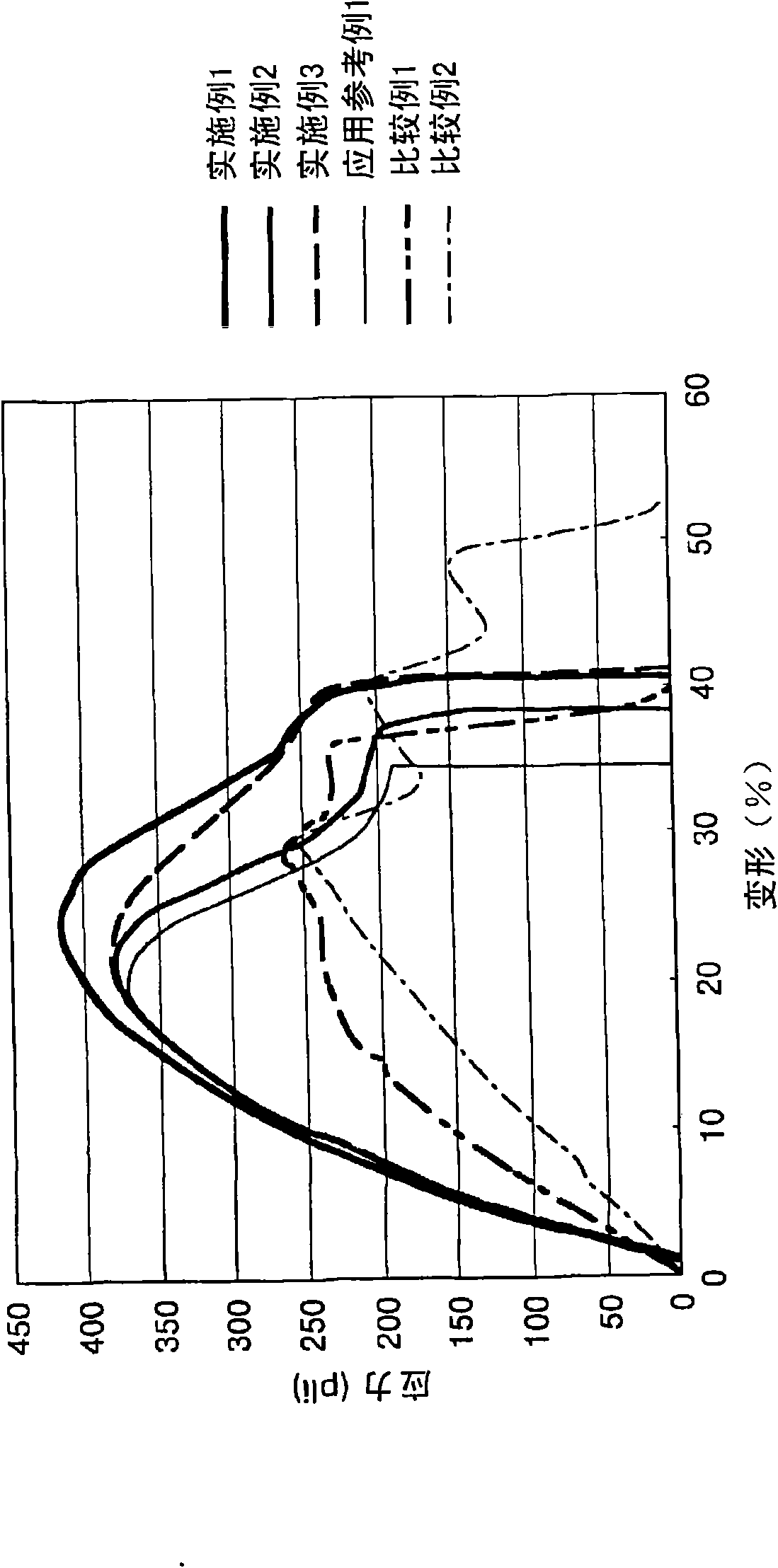

[0135] Next, in order to evaluate the physical properties of the polyurethane forming the belt 10 for a shoe press, a case where a polyurethane test piece is produced will be described.

reference example 1

[0137] A urethane prepolymer is obtained by reacting p-phenylene diisocyanate (PPDI) with polytetramethylene glycol (PTMG). A curing agent mixture was obtained using 97 mole % of 1,4-butanediol (1,4BD) and 3 mole % of 3,5-diethyltoluenediamine (ETHACURE 100).

[0138] Then, a urethane prepolymer (NCO% 5.51%, viscosity 1800 cps at 55°C, preheating temperature 66°C) and a curing agent mixture were mixed. The H / NCO equivalent ratio at this time was 0.95. In addition, this polyurethane resin mixture is simply expressed as "PPDI / PTMG / 1,4BD+ETHACURE100:H / NCO=0.95".

[0139] The mixture thus obtained was poured into a mold preheated to 127°C, the mold was heated up to 127°C, and pre-cured at 127°C for 30 minutes. Then, the upper mold was removed from the mold, and the mixture was further post-cured at 127° C. for 16 hours. Thus, a cured polyurethane sheet having a "JIS A hardness" of 98.1 degrees was obtained. A test piece (thickness: 1.5 mm) was produced from this sheet.

reference example 2

[0141] A urethane prepolymer is obtained by reacting p-phenylene diisocyanate (PPDI) with polytetramethylene glycol (PTMG). A curing agent mixture was obtained using 95 mole % of 1,4-butanediol (1,4BD) and 5 mole % of 3,5-dimethylthiotoluenediamine (ETHACURE 300).

[0142] Then, a urethane prepolymer (NCO% 5.51%, viscosity 1800 cps at 55°C, preheating temperature 66°C) and a curing agent mixture were mixed. The H / NCO equivalent ratio at this time was 0.95.

[0143] The mixture thus obtained was poured into a mold preheated to 127°C, the mold was heated to 127°C and pre-cured at 127°C for 30 minutes. Then, the upper mold was removed from the mold, and the mixture was further post-cured at 127° C. for 16 hours. Thus, a cured polyurethane sheet having a "JIS A hardness" of 98.2 degrees was obtained. A test piece (thickness: 1.5 mm) was produced from this sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap