Method for controlling pests and diseases of sugarcanes

A technology for diseases and insect pests and sugarcane, which is applied in the field of controlling sugarcane cotton aphid and other sugarcane pests, can solve the problems of poor working environment and low working efficiency of pesticide application, and achieves the effects of remarkable control effect, saving manpower and material resources, and high working efficiency of pesticide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Based on the weight of 100kg of the finished hot fog agent, 18kg of omethoate, 5kg of emulsifier, 5kg of alkylphenol polyoxyethylene ether, 1kg of calcium dodecylbenzenesulfonate, and 10kg of DMF were stirred to form a clear and transparent solution, and then supplemented with methyl naphthalene. To 100kg, stir and mix to obtain the finished preparation. Use Nantong Guangyi Electromechanical Co., Ltd. 6HY series fog machine spray test. The 18% omethoate EC produced by Guangxi Tianyuan Biochemical Co., Ltd. was used as the control agent, and the traditional method of spraying was used for control. According to the statistics, the average time per mu of the hot fog machine spraying method and the normal pressure spraying method are 3.5min and 152min respectively. The control effect results are shown in Table 1.

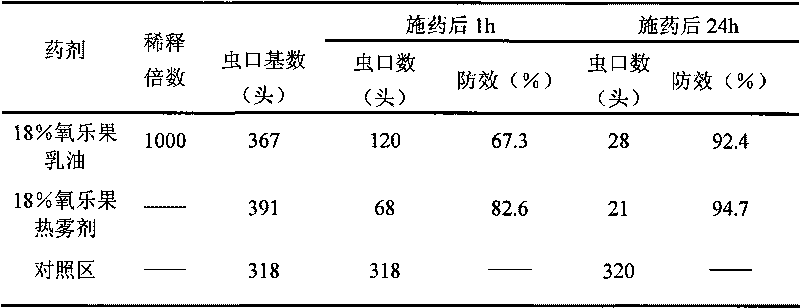

[0017] Table 1 Field test results of 18% omethoate hot spray and 18% omethoate EC to control sugarcane cotton aphid

[0018]

Embodiment 2

[0020] Based on the weight of 100kg of the finished product, stir 10kg of dichlorvos, 5kg of emulsifier, 5kg of alkylphenol polyoxyethylene ether, 1kg of calcium dodecylbenzenesulfonate, and 30kg of trimethylbenzene to form a clear and transparent solution, then make up to 100kg with diesel , Stir and mix uniformly to obtain a finished preparation. Use Nantong Guangyi Electromechanical Co., Ltd. 6HY series fog machine spray test. Take Jina EC (10% hyperosmolar dichlorvos EC) produced by Guangxi Tianyuan Biochemical Co., Ltd. as the control agent, and use the traditional method of spraying for control. According to the statistics, the average time per mu of the hot fog machine spraying method and the normal pressure spraying method are 3.2min and 145min respectively. The control effect results are shown in Table 2.

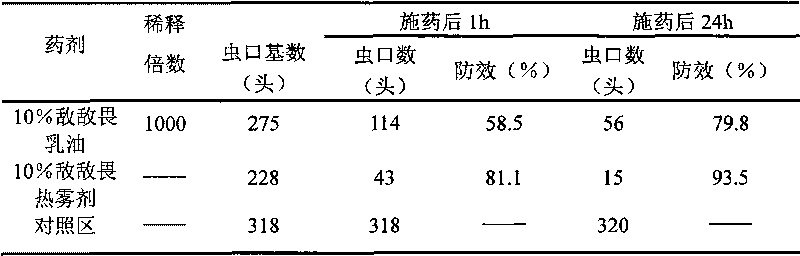

[0021] Table 2 Field test results of 10% dichlorvos hot spray and 10% dichlorvos EC to control sugarcane cotton aphid

[0022]

Embodiment 3

[0024] Based on the weight of 100kg of the finished product, stir 20kg of chlorpyrifos, 5kg of emulsifier, 5kg of alkylphenol polyoxyethylene ether, 1kg of calcium dodecylbenzenesulfonate, and 30kg of trimethylbenzene to form a clear and transparent solution, and then make up to 100kg with diesel , Stir and mix uniformly to obtain a finished preparation. Use Nantong Guangyi Electromechanical Co., Ltd. 6HY series fog machine spray test. Chlorpyrifos (480g / L hypertonic dichlorvos emulsifiable concentrate) produced by Guangxi Tianyuan Biochemical Co., Ltd. was used as the control agent and sprayed by traditional spraying methods. According to the statistics, the average time per mu of the two spraying methods of hot fog machine spraying method and atmospheric pressure spraying method is 4.1min and 161min respectively. The control effect results are shown in Table 3.

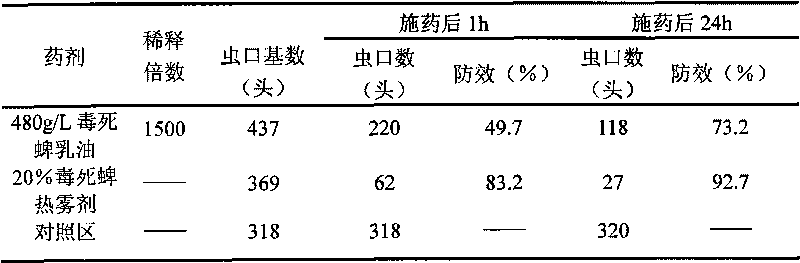

[0025] Table 3 Field test results of 20% chlorpyrifos hot spray and 480g / L chlorpyrifos EC to control sugarcane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com