Pesticidal composition and pesticide

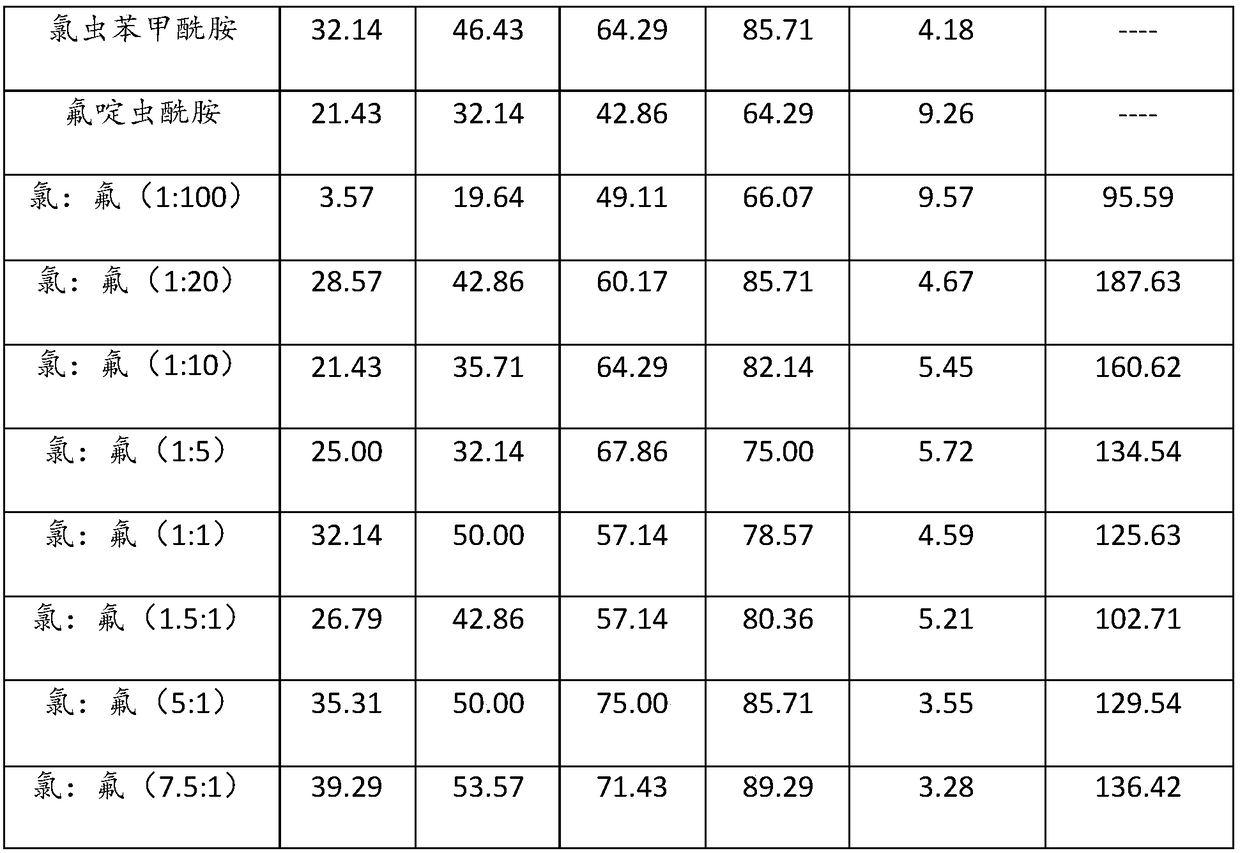

An insecticidal composition and insecticide technology, applied in the field of pesticides, can solve the problems of synergistic effect of flonicamid and chlorantraniliprole, etc., and achieve the advantages of saving pesticide application costs, convenient use, and enhancing resistance to diseases and insect pests effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Formula among the present invention: flonicamid 1%, chlorantraniliprole 0.5%, ore powder 80%, dispersant 2%, binding agent 3%, surfactant 3%, all the other fillers make up. Wherein the dispersant is corn starch, the binder is industrial gelatin, the surfactant is sodium lignosulfonate, and the filler is calcium carbonate.

[0053] (2) The production method of ore powder: the calcination process of natural ore destroys the layered crystal structure of ore, forms a porous structure between layers, expands the adsorption capacity and specific surface area, and improves the activity of minerals. The calcination process of ore: raw material→dry grinding→calcination (700-860℃)→wet superfine grinding→drying→dispersion→ore powder.

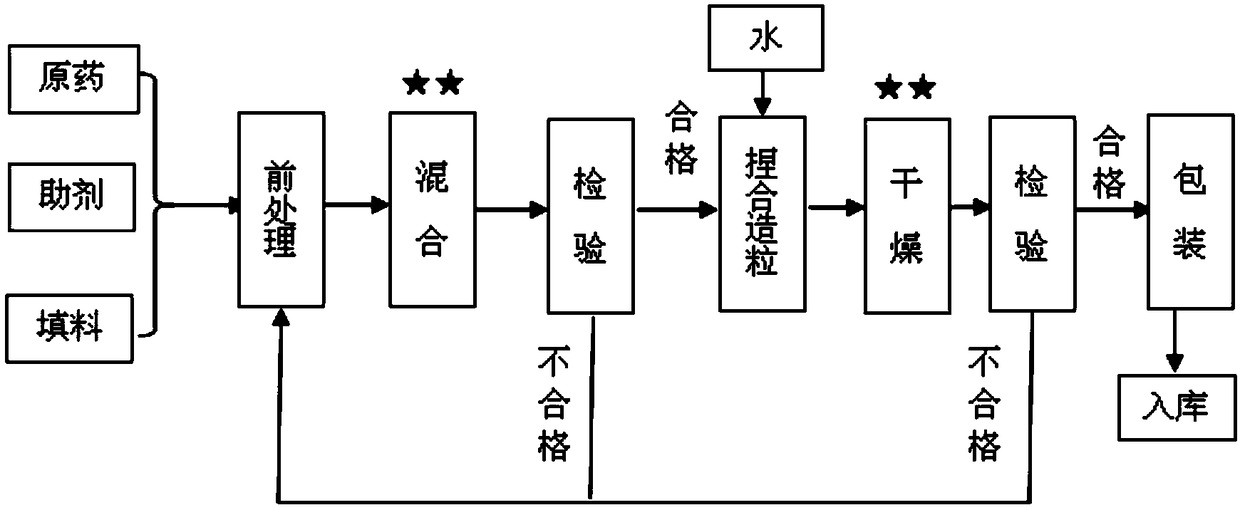

[0054] (3) The production process of granules (see figure 1 ): Accurately weigh the ingredients in (1) according to the requirements of the formula, carry out pretreatment, put them into the conical mixer for full stirring and mixing, and take ...

Embodiment 2

[0056] (1) Formula among the present invention: flonicamid 0.5%, chlorantraniliprole 0.5%, ore powder 80%, dispersant 2%, binding agent 3%, surfactant 3%, all the other fillers make up. Wherein the dispersant is corn starch, the binder is industrial gelatin, the surfactant is sodium lignosulfonate, and the filler is calcium carbonate.

[0057] (2) The production method of ore powder: the calcination process of natural ore destroys the layered crystal structure of ore, forms a porous structure between layers, expands the adsorption capacity and specific surface area, and improves the activity of minerals. The calcination process of ore: raw material→dry grinding→calcination (700-860℃)→wet superfine grinding→drying→dispersion→ore powder.

[0058] (3) Production process of granules: Accurately weigh each component in (1) according to the requirements of the formula, carry out pretreatment, put them into a conical mixer for full stirring and mixing, and take samples to test after ...

Embodiment 3

[0060] (1) Formula in the present invention: formula in the present invention: flonicamid 1.2%, chlorantraniliprole 0.8%, ore powder 80%, dispersant 2%, binding agent 3%, surfactant 3 %, the rest of the fillers make up. Wherein the dispersant is corn starch, the binder is industrial gelatin, the surfactant is sodium lignosulfonate, and the filler is calcium carbonate.

[0061] (2) The production method of ore powder: the calcination process of natural ore destroys the layered crystal structure of ore, forms a porous structure between layers, expands the adsorption capacity and specific surface area, and improves the activity of minerals. The calcination process of ore: raw material→dry grinding→calcination (700-860℃)→wet superfine grinding→drying→dispersion→ore powder.

[0062] (3) Production process of granules: Accurately weigh each component in (1) according to the requirements of the formula, carry out pretreatment, put them into a conical mixer for full stirring and mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com