Nano/micron invisible nasal mask and production process and dedicated wearing device thereof

An invisible nasal mask and nanotechnology, which is applied in the field of human nasal filter devices, wearers, and invisible nasal masks, can solve the problems of unsatisfactory invisible effects of U-shaped rings, excessive area occupied by filter brackets, and high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

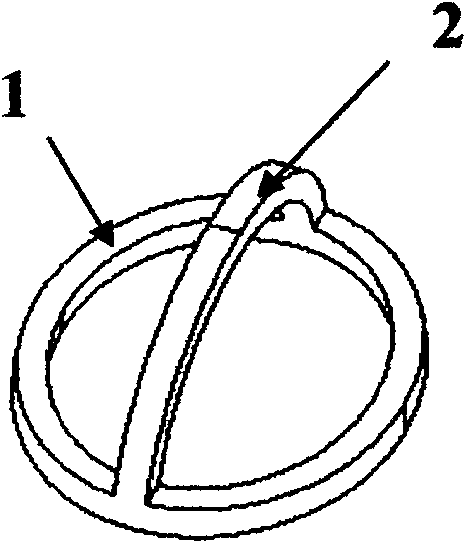

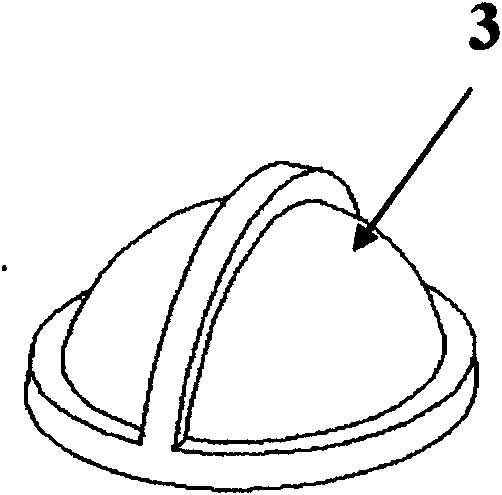

[0021] First made with plastic technology figure 1 For the elastic filter bracket with arc support 2, several metal tool plates with several pits are made, and there are grooves corresponding to the elastic filter bracket in the pits of the metal tool plates, and the figure 1 The elastic filter brackets are respectively embedded in the pits of the metal plate. In order to enable the fiber mat to be peeled off from the metal tool smoothly after spinning, a lubricant or release agent can be applied to the surface of the metal tool before spinning. Then, using melt spinning method or nano electrospinning method, the required high molecular polymer melt or solution is sprayed on a rotating metal plate equipped with several elastic filter holders, and the spun high molecular polymer A cross-linking agent is added to the material or the surface of the filter support, and the nano / micro fibers are attached to the elastic filter support through the cross-linking technology of the cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com