Process for producing closed-cell foam-cell polyurethane elastomer coiled materials

A polyurethane elasticity and manufacturing process technology, applied in elastic floors, roads, pavements, etc., can solve the problems of affecting the service life of sports ground, affecting the flatness of the ground, affecting the performance of athletes, etc., to achieve good elasticity, easy control, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

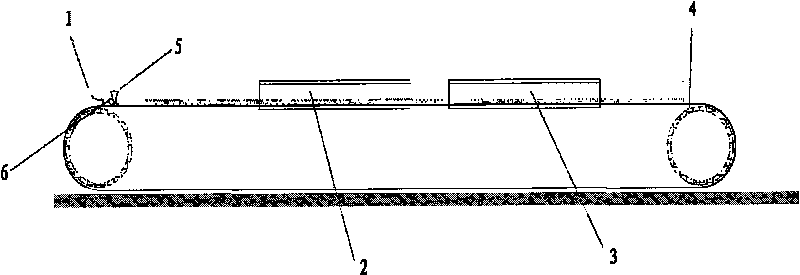

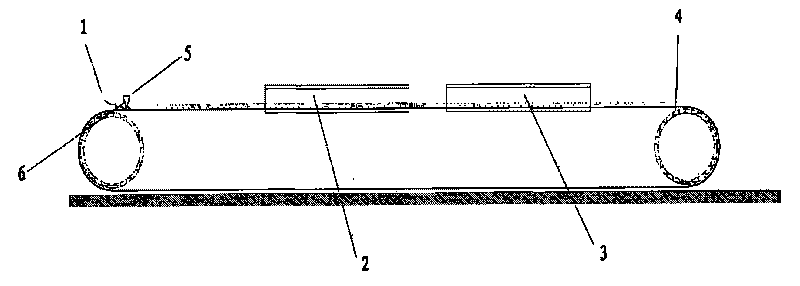

[0010] See figure 1 In the present invention, 30% of the volume of polyphenyl foam particles are uniformly mixed in a polyurethane elastomer viscous liquid at 60-70°C, and the particle size of the polyphenyl foam particles is Φ0.5mm. Stir evenly, a polyurethane polystyrene foam mixture 1 in a viscous liquid state. Then, the polyurethane-polystyrene foam mixture 1 in a viscous liquid state is scraped on the flow belt base 6 through the scraper 5, and the thickness of the polyurethane-polyphenyl foam mixture 1 is 3mm-25mm by the scraper 5. The polyurethane polystyrene foam mixture 1 is sent from the belt base 6 into the 70°C low-temperature drying tunnel 2 and heated in the drying tunnel 2 for 40 minutes, and the polyurethane liquid is cured. Then, the belt base 6 sends the cured polyurethane polystyrene foam mixture 1 into a high-temperature drying tunnel 3 at 80° C.-90° C., where it is heated for 10 minutes. The polyphenyl foam particles disappeared, and the polyphenyl foam p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com