Electrothermal speed controller of silicon oil fan

A speed control controller, electronic controller technology, applied in the direction of coolant flow control, clutch, fluid clutch, etc., can solve the problems that cannot be widely used, and the fixing method is difficult, etc., to achieve less moving parts, high reliability, The effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: see Figure 8 , The electric fan 1 is installed in front of the intercooler A and blows backward. An air duct 4 is coaxially installed behind the intercooler A, which overlaps with another air duct 4 installed in front of the cooler B. The electric heater 2 is installed coaxially with the air duct 4, and all axes are consistent with the center of the silicon oil fan clutch C. There is a wind mask 5 at the rear of the electric heater 2 to concentrate the hot air and adjust the gap. After the electric fan 1 is started, the blown air is heated by the intercooler A and the cooler B, and then is compensated by the electric heater 2 according to the control strategy and then blown to the bimetallic temperature sensor D of the silicon oil fan clutch C. After the electric heater 2 is used, the temperature of intercooler A and cooler B is no longer completely dependent, and the fan speed hysteresis effect caused by the temperature sensor is overcome, and the silicone ...

Embodiment 2

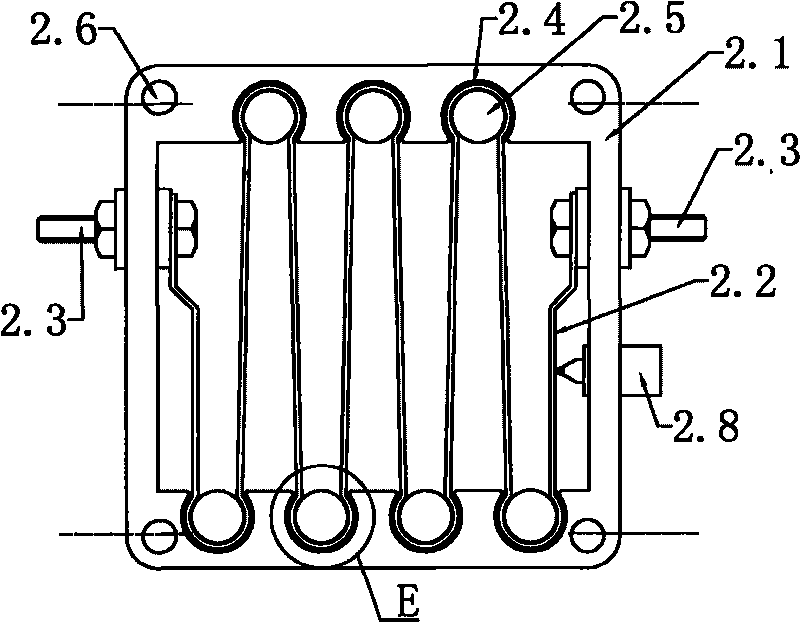

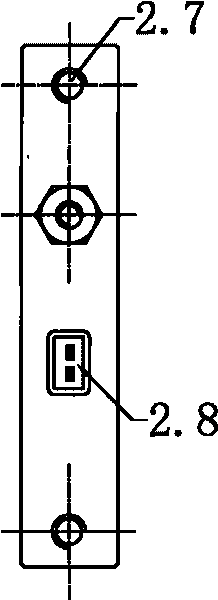

[0041] Example 2: see Picture 9 , The electric fan 1 is combined with the electric heater 2 and the air mask 5 to form a hot air blower, which is installed on the bracket E connected to the cooler behind the cooler B, and enters the electric fan 1 through the intercooler A (not shown) ), the air heated by the cooler B is further heated by the electric heater 2 and then blown to the bimetallic temperature sensor D of the silicon oil fan clutch C. After electric heater 2 is used, the temperature of intercooler A and cooler B is no longer completely dependent, and the hysteresis effect of fan speed is overcome, and the silicon oil fan clutch C can be intelligently controlled according to the temperature change rate, so that the coolant temperature is kept in the ideal range , To achieve the purpose of energy saving and emission reduction.

Embodiment 3

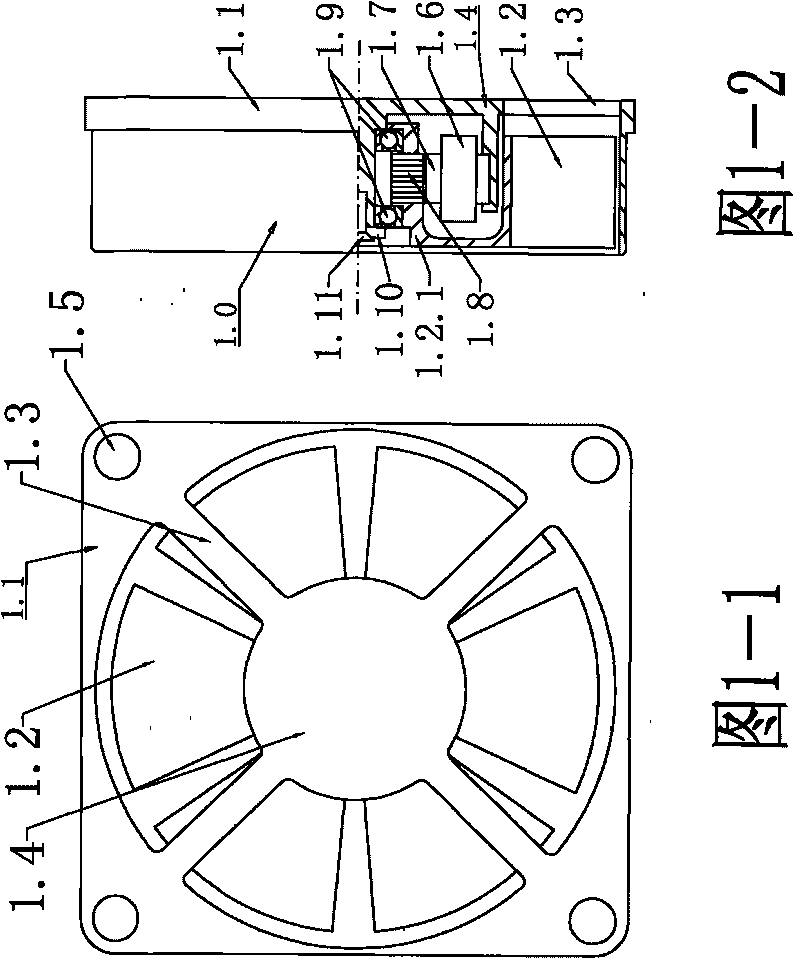

[0042] Example 3: See Picture 10 ,will image 3 The shown integrated hot air blower (the casing 1-2) is installed on the bracket E connected to the cooler behind the cooler B, and the hot air is blown to the bimetallic temperature sensor D of the silicone oil fan clutch C through the air mask 5.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap