Closed type pipe clamp assembly with vibration-proof structure

A vibration-damping structure and closed technology, applied in the direction of pipes/pipe joints/fittings, pipe supports, vehicle parts, etc., can solve the problems of high development cost, high vibration and noise of the whole vehicle, long installation and disassembly time, etc. The effect of convenience and reliability, reducing the contact area and reducing the development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, structure of the present invention is further described in detail:

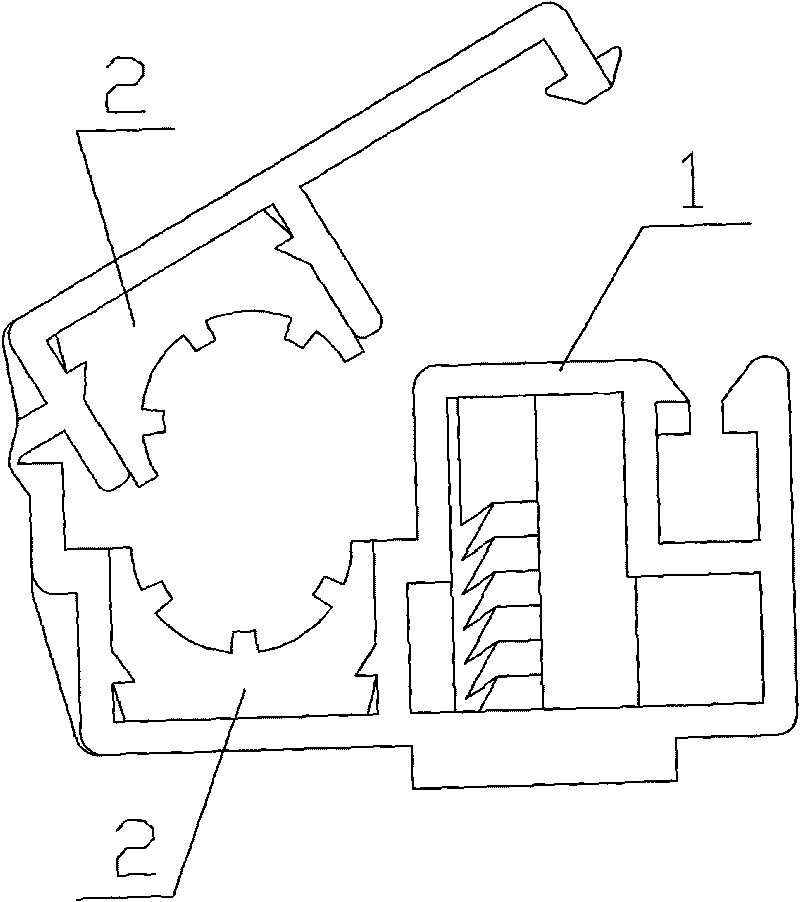

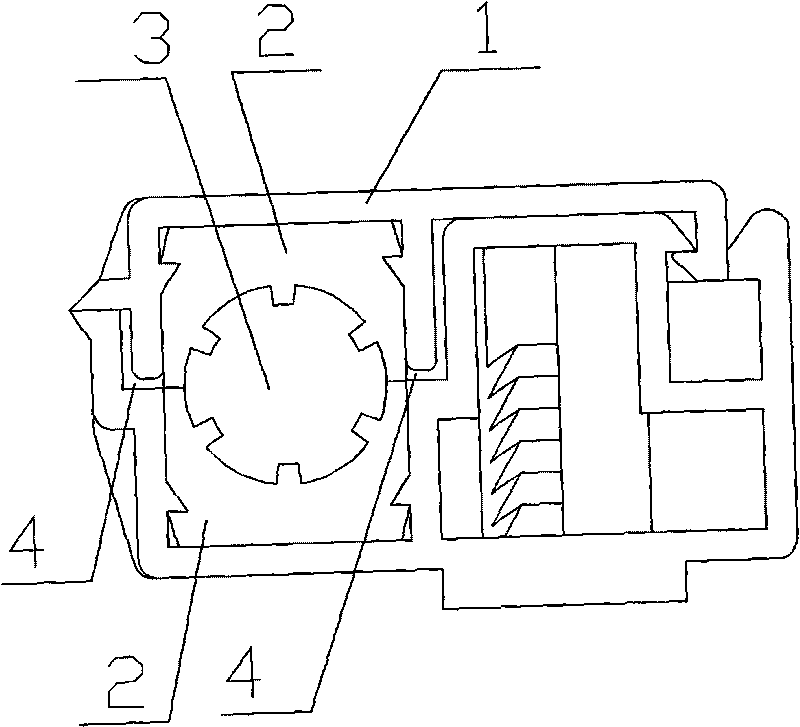

[0026] see figure 1 with figure 2 , The pipe clamp assembly consists of a pipe clamp body 1 and a vibration damping pad 2.

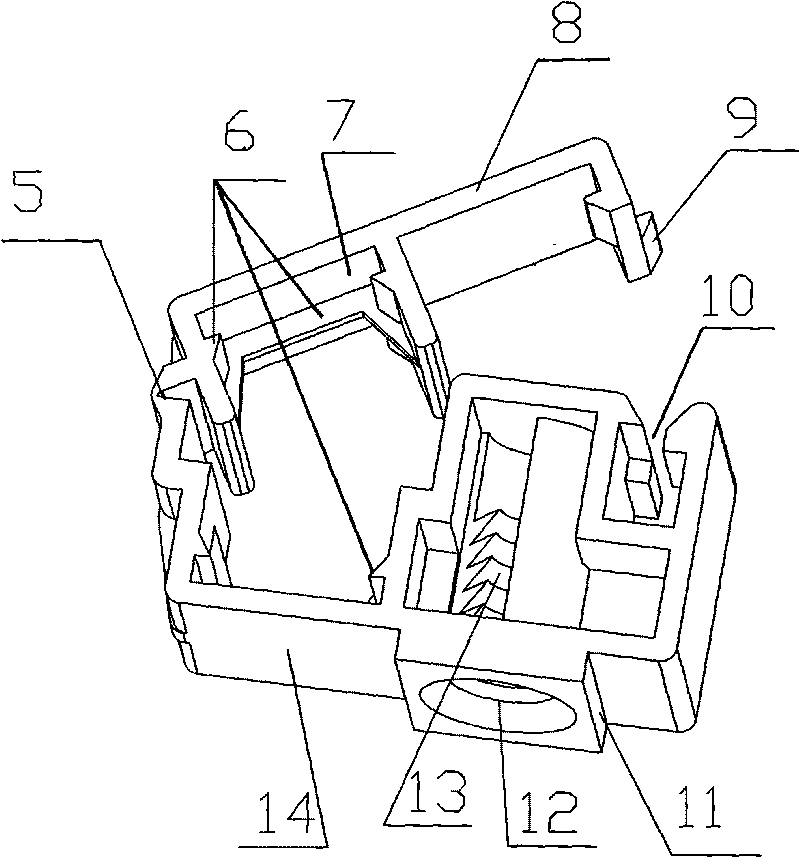

[0027] see in conjunction image 3 with Figure 4 , the pipe clamp body 1 is composed of a pipe clamp seat 14 and a pipe clamp cover 8. One end of the pipe clamp cover 8 is connected to the pipe clamp seat 14 through a flexible connecting strip 5 integrally injection molded with them. The flexible connecting strip 5 is thinner and There is a certain elasticity, so that the pipe clamp cover 8 can rotate around the flexible connecting strip 5.

[0028] There is a half-hole groove 7 on the pipe clamp cover 8, and there is a toothed chuck 9 at the end of the pipe clamp cover 8. Correspondingly, the pipe clamp seat 14 has another half hole 7 corresponding to the pipe clamp cover 8 and a slot 10 with inverted teeth. When the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com