Method for sampling metal material sample

A metal material, sampling space technology, applied in the sampling device and other directions, can solve the problems of deflection and breakage of the drill bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

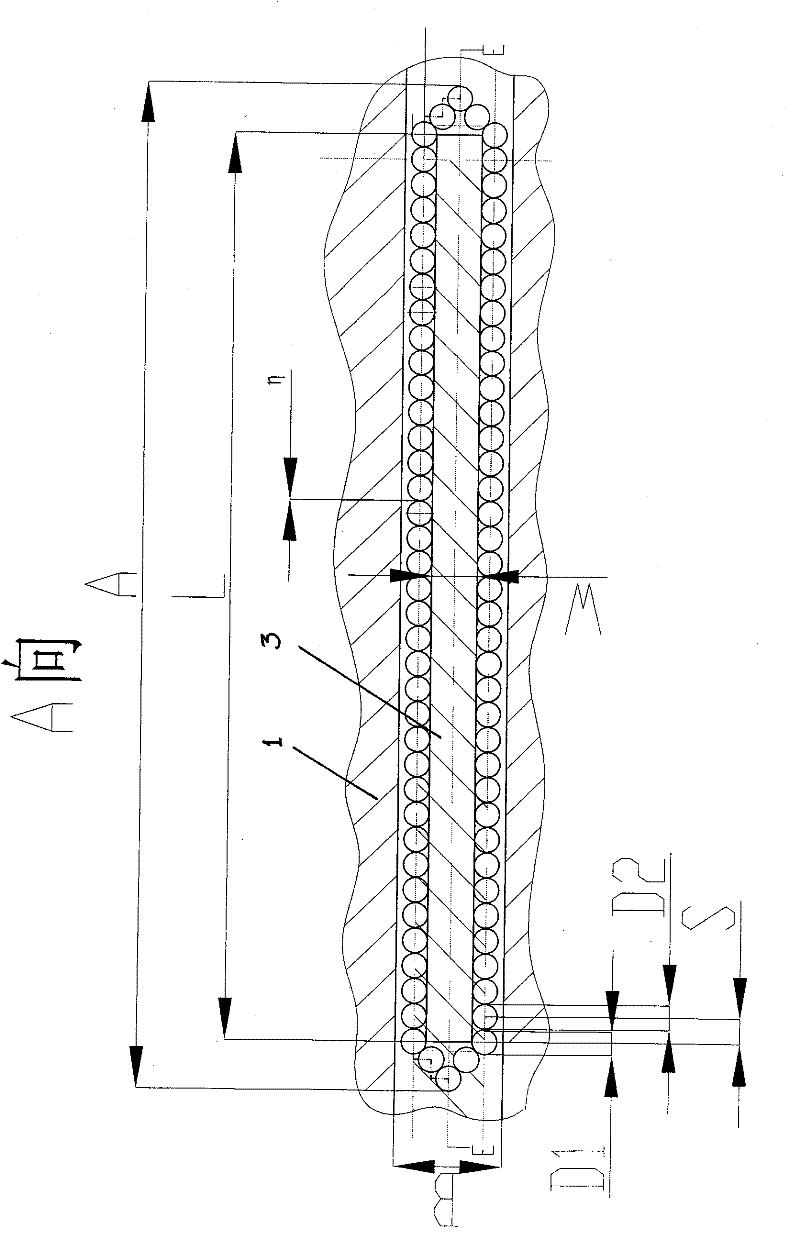

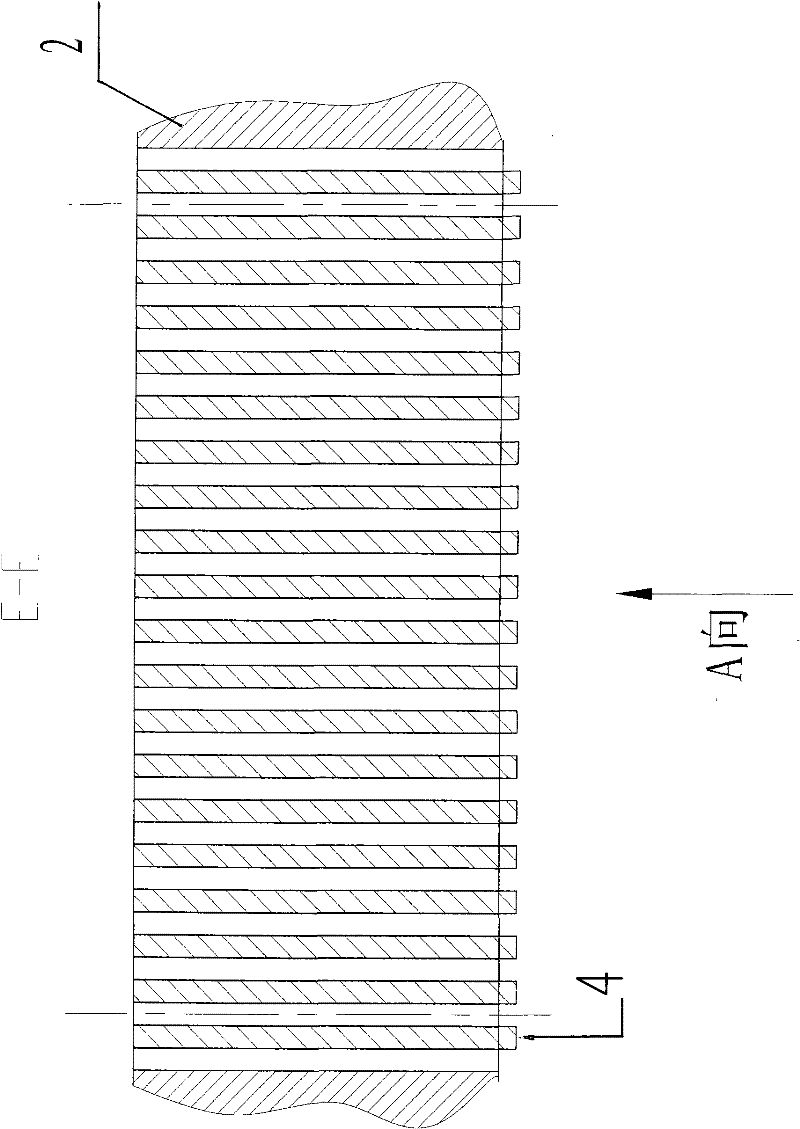

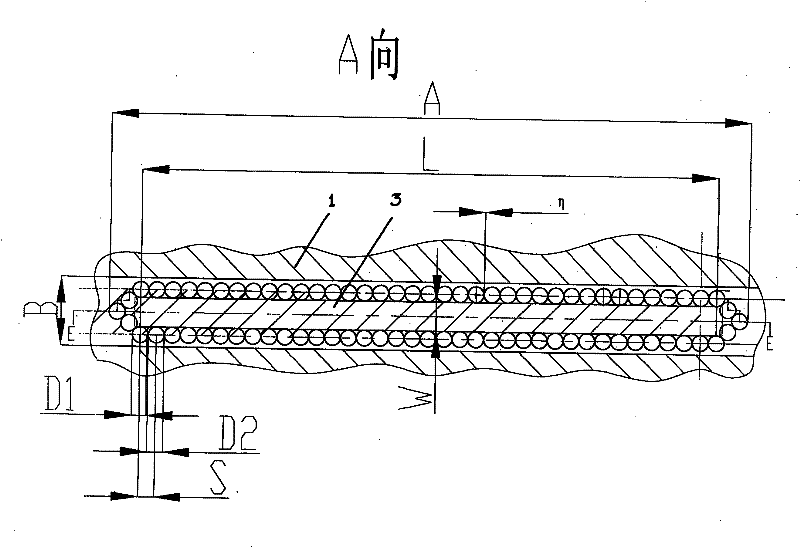

[0021] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, it is necessary to remove the weld bead inspection materials whose length L, width and thickness W are 200mm, 100mm, and 11mm respectively within the scope of the weld bead 2 with a width of 26mm. In order to ensure that the body 1 is not damaged, the sampling method of the present invention is adopted, including The following steps:

[0022] A. According to the width B=26mm of the sampling weld bead 2 and the width W=11mm of the sample 3, determine the diameter D2 of the gun drill bit D1 and the twist drill bit, that is, D1+D2<(B-W), and D1=D2 is selected in this embodiment =D=6mm, and determine the shortest processing length A according to the length L=200mm required by sample 3 and the diameter D1=6mm of the gun drill bit;

[0023] B. Use the gun drill to perform jump drilling along the center line of the drilled hole of the sample to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com