Electrolysis water heater

An electrolytic water heater and relay technology, used in water heaters, fluid heaters, water/sewage treatment, etc., can solve the problems of high price, inconvenient disassembly, cleaning, poor safety and energy saving, etc. Thermal conductivity, time and energy saving, ease of operation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

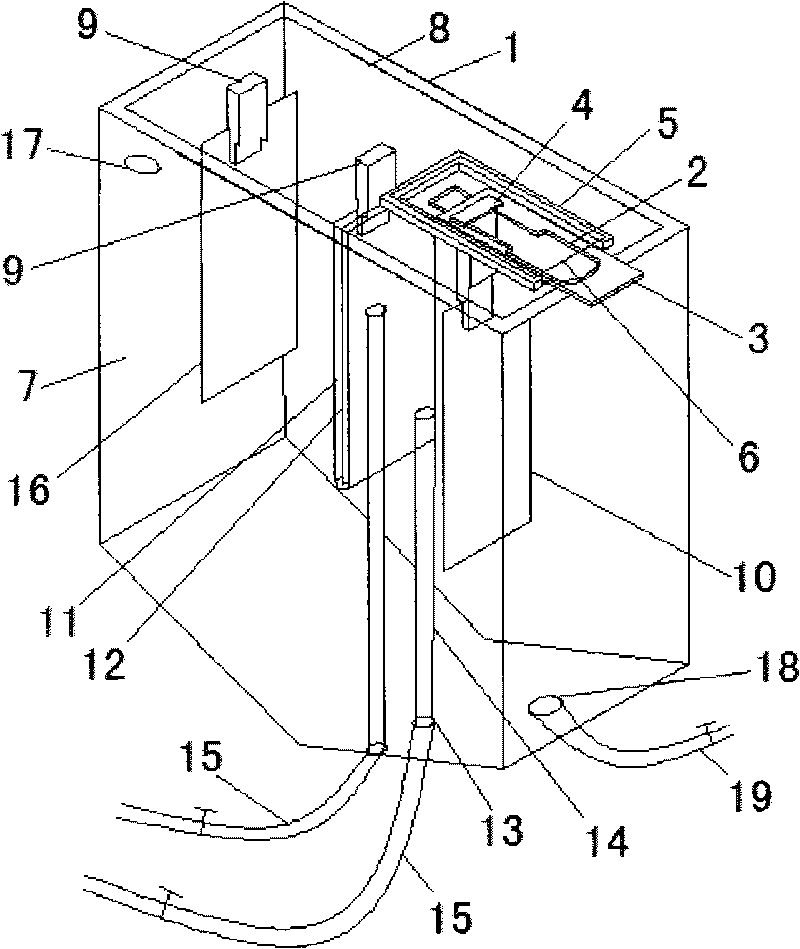

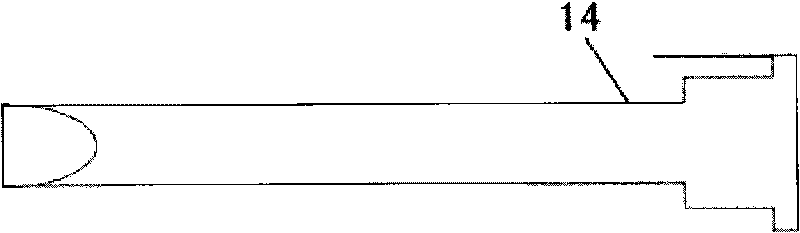

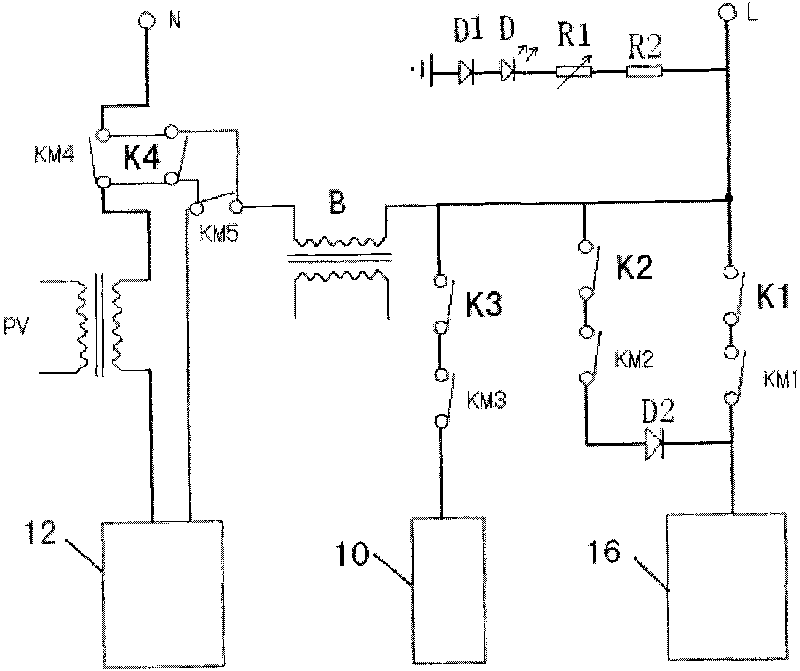

[0012] Such as figure 1 , figure 2 As shown, it includes end cover 1, T-shaped slot 2, control panel 3, slider 4, U-shaped step 5, cover plate 6, water tank 7, control circuit 8, hanger 9, fast heating anode plate 10, net sleeve 11. Cathode plate 12, water outlet hole 13, water guide pipe 14, water outlet hose 15, anode plate 16, feed hole 17, water inlet and outlet holes 18, water inlet and outlet hose 19, characterized in that: there is a T on the end cover 1 T-shaped slot 2 and T-shaped slot 2 are connected to the control panel 3, and one end of the control panel 3 has a hole that can be set on the upper end of the slider 4, and the upper end of the slider 4 is stuck in the T-shaped slot 2 and the slider 4 can be controlled by the control panel 3. The fast heating anode plate 10 is fixed on the lower end of the slider 4, and the distance between the pole plates can be adjusted by moving the slider 4, so that the size of the current can be adjusted. The three sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com