Foaming tool

A tool, all-in-one technology, applied in packaging, single hand-held devices, spray devices, etc., can solve the problems of inability to construct inner channels, prone to cracks, blockages, etc., to improve fastness and sealing stability, good leak-proof performance , high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

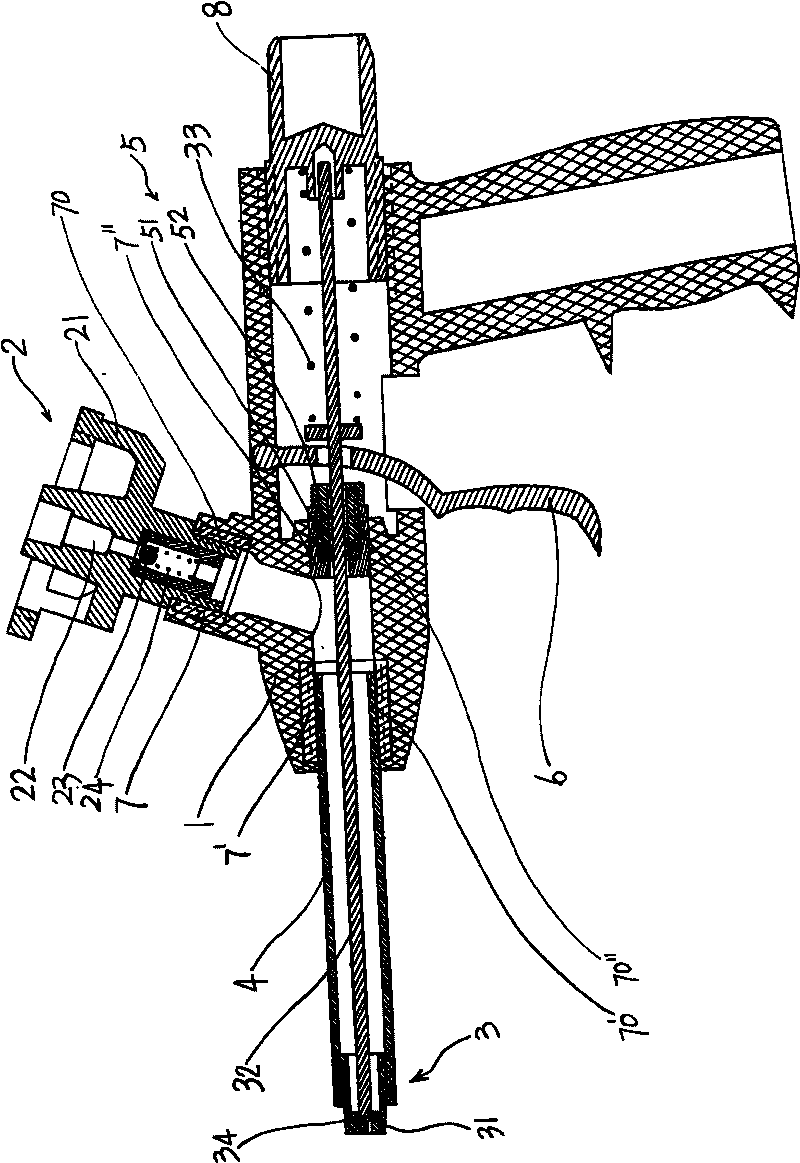

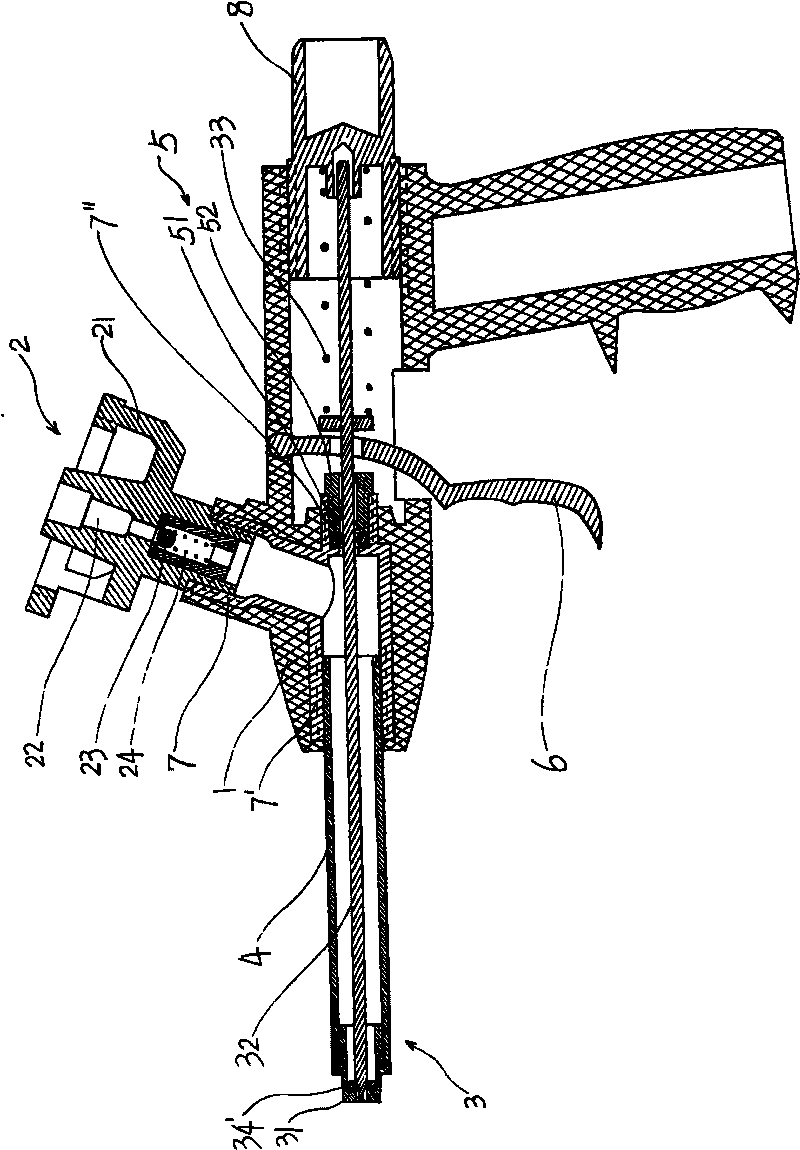

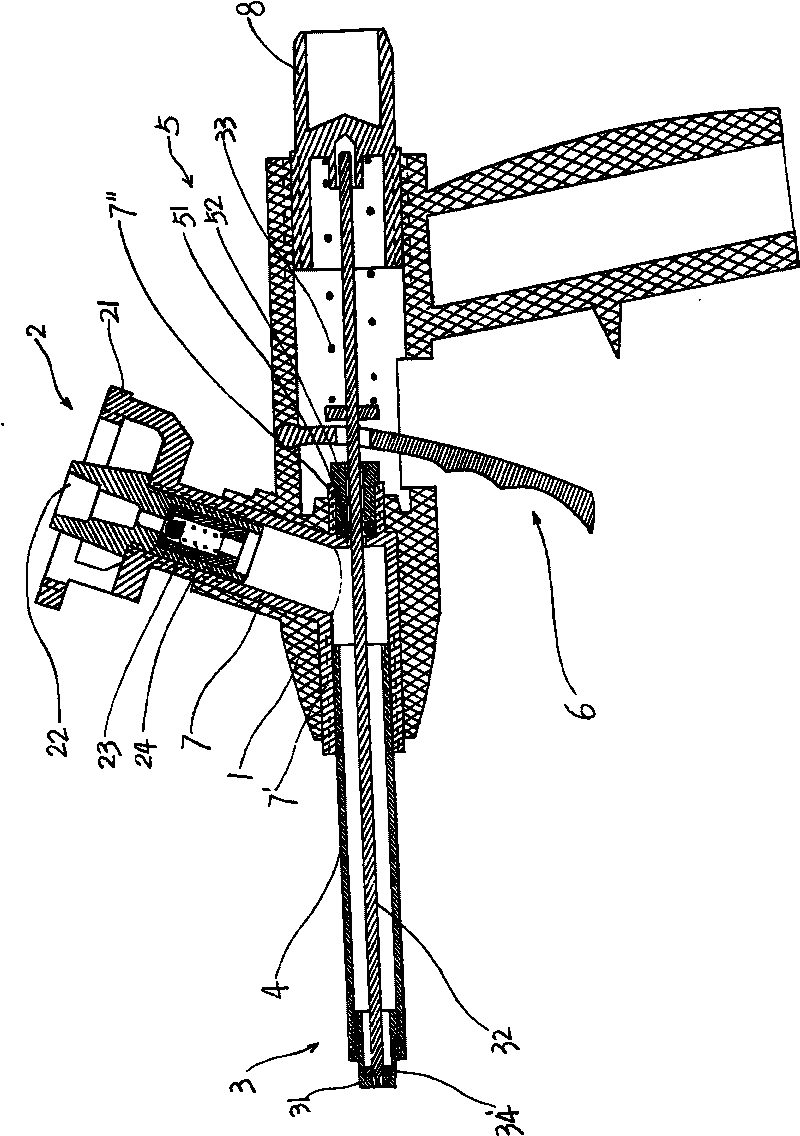

[0066] The foaming tool of the present invention, referring to all accompanying drawings, includes a gun body 1, a liquid inlet valve 2, a liquid outlet valve 3, a liquid outlet pipe 4, a sealing device 5 and a switch device 6, and the liquid inlet valve 2 includes a valve body 21, an inlet valve The liquid port 22 and the closing device, the liquid outlet valve 3 includes a liquid outlet nozzle 31, a valve core 32 and a return spring 33, the valve core 32 protrudes from the inner passage of the gun body 1 and is sealed with the gun body 1 by a sealing device 5, The switch device 6 can move the spool 32 to open or close the liquid nozzle 31. It is characterized in that: the gun body 1 is made of plastic, and the first connecting pipe 7 or the second connecting pipe 7 is embedded in the gun body 1. pipe 7 ′ or a third connecting pipe 7 ′, the valve body 32 is at least partly connected to the first connecting pipe 7 , or the outlet pipe 4 is connected to the second connecting pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com