Magnetic powder brake water cooling structure

A magnetic powder brake and water cooling technology, which is applied in the direction of brake types, slack regulators, mechanical equipment, etc., can solve the problems of large impact on the production process, high cost, looseness at the water connection, etc., and achieve good sealing and leak-proof effect, structure Reasonable and stable, easy to disassemble and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

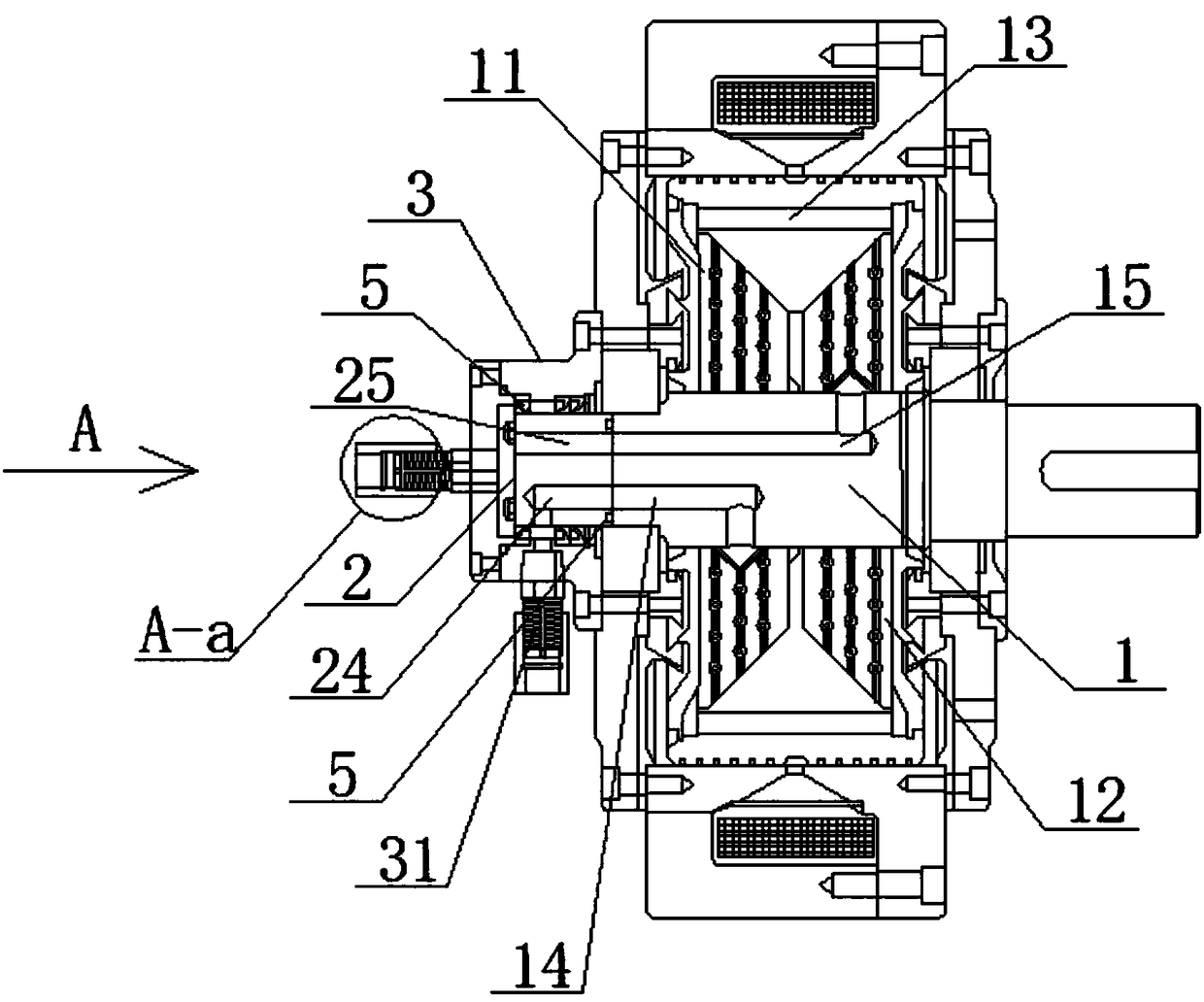

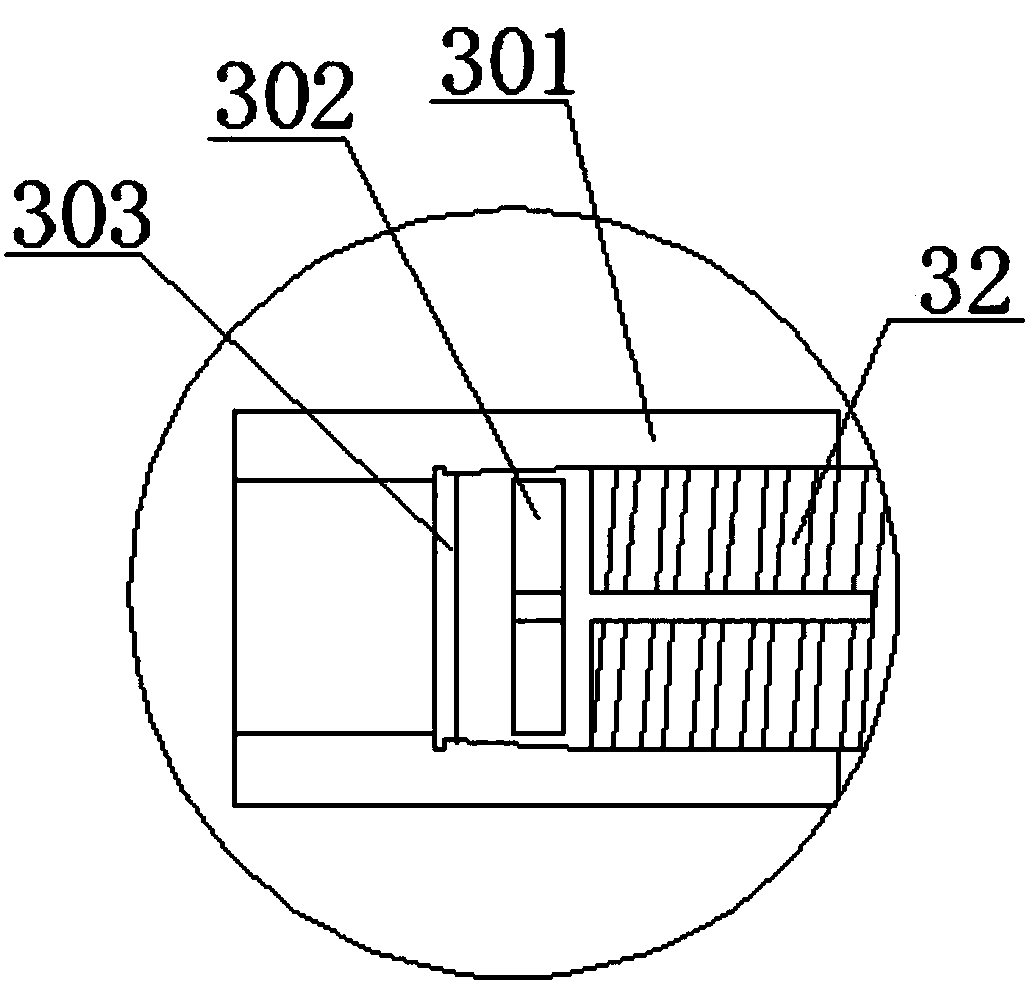

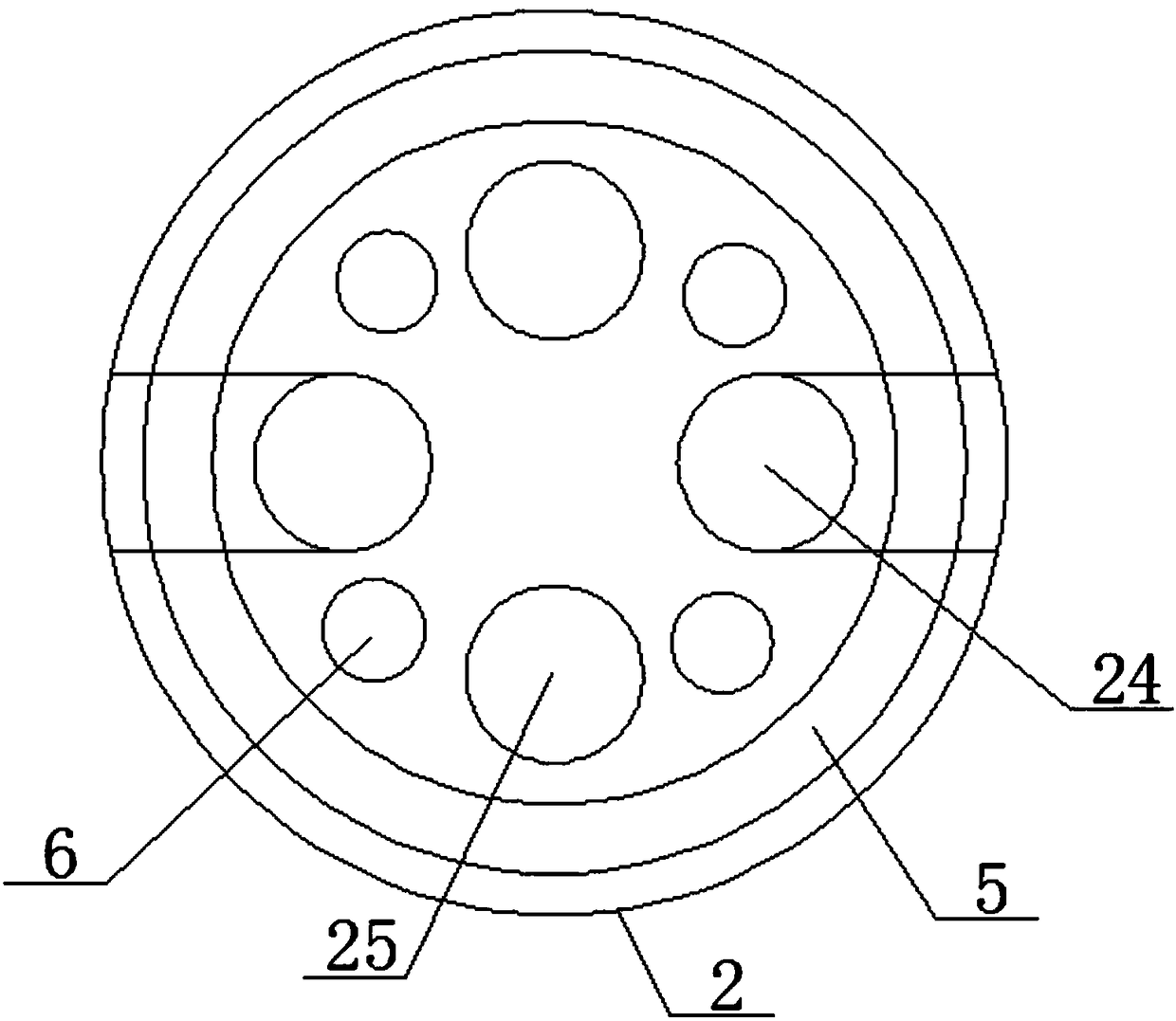

[0021] Such as Figure 1 to Figure 4 As shown, a magnetic powder brake water cooling structure includes a rotor assembly 1 that can rotate around an axis and a cooling shaft 2 coaxially and detachably fixed on the rotor assembly 1 . In the present invention, the cooling shaft 2 refers to a piece of workpiece that is detachably connected to the rotor assembly and has friction with the water seal cover 3 . In the prior art, the integrated casting of the rotor assembly and the output shaft is difficult and costly. To ensure power transmission, the rotor assembly and the output shaft are generally forged separately and then welded together. This is obviously different from the design of the present invention which is provided with the cooling shaft 2 and detachably connected to the rotor assembly, and the cooling shaft 2 is generally also a part of the output shaft and cannot be confused with the output shaft.

[0022] The above-mentioned water cooling structure for the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com